Powermate PW0923500 User Manual

Page 6

Following is information concerning the four nozzles pro-

vided with your pressure washer.

NOTE: The force of the spray on the surface you are

cleaning increases as you move closer to the surface.

0° High Pressure (Red): The water stream discharged is

very aggressive. Use with extreme caution to prevent damage

to the surface being cleaned or injury to persons or animals.

15° High Pressure (Yellow): This is the nozzle used for

most cleaning applications. It provides wide coverage and a

powerful water stream.

40° High Pressure (White): This nozzle is used for

cleaning with a wider coverage over a larger area with a

powerful water stream.

65° Low Pressure (Black): Provides low pressure spray

and a wide coverage. Used primarily when operating the

chemical injector to apply chemicals.

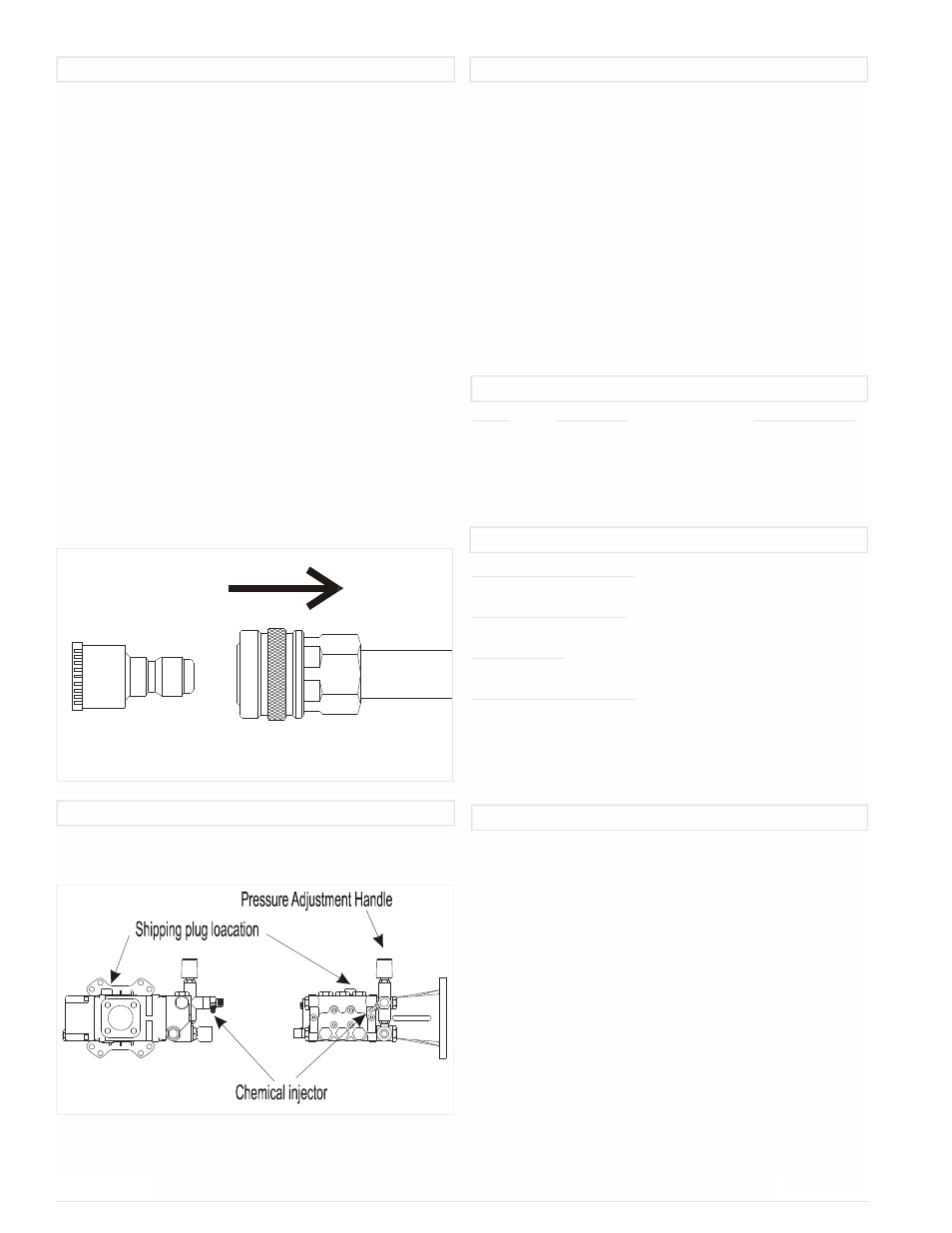

Replacing the Nozzles

To replace a nozzle with a different nozzle, an easy quick

connect has been added to the end of the wand. With the

handle in the locked close position and the wand pointing

away from the user. Pull back on the quick connect fitting and

pull out the nozzle and replace with desired nozzle.

The pump is shipped with a shipping plug, this will need

to be replaced with the vent plug that is supplied.

PRESSURE ADJUSTMENT

The pressure is adjustable by turning the pressure adjust-

ment knob located on the pump of the pressure washer. The

knob must be set at the extreme clockwise position for maxi-

mum pressure and turned several turns counter clockwise for

maximum pressure.

NOTE: With the pressure adjustment knob turned to

the maximum pressure position (clockwise), the pump

pressure may exceed the rated pressure of the machine

which could over load the engine. Adjust the knob counter

clockwise to reduce the pressure and lower the power

requirements of your pressure washer pump.

The pressure may also be regulated by the use of the

engine speed.

6

Item#

Description

Torque Amount

6

Screw

43 in.-lbs

10

Screw with Lock Washer

85 in.-lbs.

34

Hex Head Cap Screw,

222 in.-lbs.

Valve Casing

32

Plug

59 in-lbs.

Inlet Pressure . . . . . . . . . . . . .Positive Inlet Pressure Required

RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Up to 3600 RPM

Temperature of Pumped Fluids . . . . . . . . . . . . . . .Up to 160°F

Inlet Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(2) 1/2” BSP

Discharge Ports . . . . . . . . . . . . . . . . . . . . . . . . . . .(2) 3/8” BSP

Key Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8mm

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 lbs.

Crankcase oil Capacity . . . . . . . . . . . . . . . . . . . . . . .14.2 fl. oz.

Change oil after (HR) . . . . . . . . . . . . . .Initially 50/Every 500

Consult the pump manufacturer for special requirements that

must be met if the pump is to operate beyond one or more of

the limits specified above.

Plunger Packing Kit (9152)

Order # 0057908

Valve Assembly Kit (9116)

Order # 0057909

Oil Seal Kit (9144)

Order # 0057910

Unloader Repair Kit (9516)

Order # 0057962

P321 SERIES TORQUE SPECIFICATIONS

P321 SERIES REPAIR KITS

P321 SPECIFICATIONS

SPRAY NOZZLE SELECTION

PUMP PREPARATION

PRESSURE ADJUSTMENT

English