Maintenance schedule, Lgj control connection diagram, Open and close control options – LiftMaster LGJ Light-Duty Gear-Reduced Jackshaft Operator for Rolling Grilles and Shutters User Manual

Page 10: Switch adjustments

10

15

LISTED DOOR OPERATOR

41B6

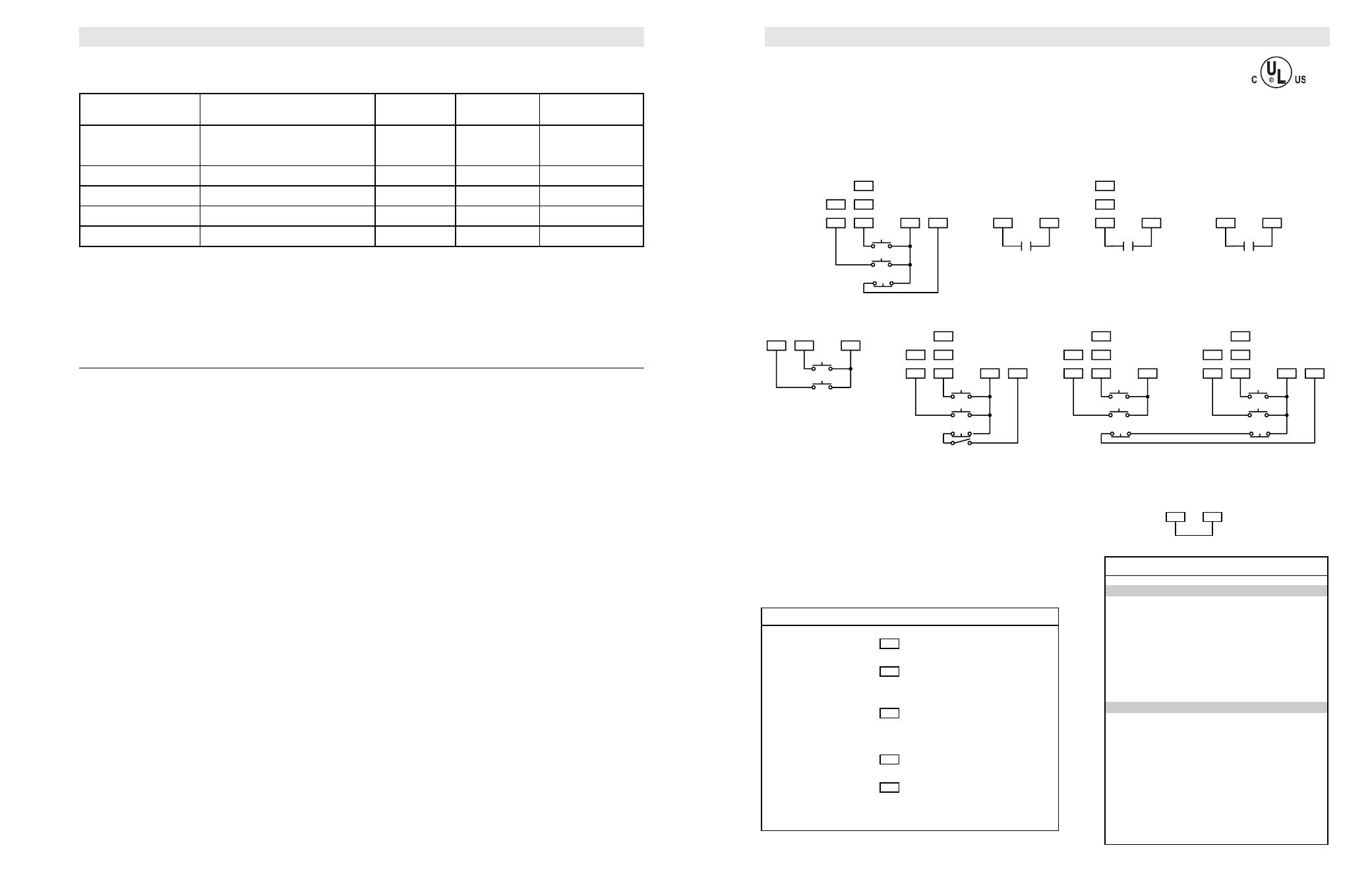

LGJ CONTROL CONNECTION DIAGRAM

NUMBERED BOXES CORRESPOND WITH TERMINALS ON J1 CONNECTOR STRIP

If Neccessary, Remove The Connector Block From The Board To Secure Each Wire Connection

Connect field wires to any terminal number shown in the respective column. See control

options below for explanation of how field control will function for each terminal number.

OR

OR

OR

11

9

7

8

4

3

5

OPEN

CLOSE

STOP

STANDARD

3 BUTTON CONTROL

10

5

SENSING

EDGE

8

5

9

11

ANY OPEN

CONTROL

(SEE NOTE)

6

5

ANY

OPEN & CLOSE

CONTROL

(SEE NOTE)

OR

OR

OR

11

9

7

8

4

3

5

OPEN

CLOSE

STOP

OR

OR

OR

11

9

7

8

4

5

OPEN

CLOSE

STOP

OR

OR

OR

11

9

7

8

4

3

5

OPEN

CLOSE

STOP

OR

OR

11

4

5

OPEN

OFF

ON

CLOSE

2 BUTTON

CONTROL

(SEE NOTE)

3 BUTTON CONTROL

WITH

KEYED LOCK-OUT

3 BUTTON CONTROL

WITH

MULTIPLE CONTROL STATIONS

WHEN CONNECTING AN

OPEN CONTROL TO:

- Open control will require constant

pressure to keep door moving.

- Open control will only require

momentary contact and will set or

reset timer to close.

- Open control will only require

momentary contact and will NOT

set or reset timer to close.

WHEN CONNECTING AN

CLOSE CONTROL TO:

- Close control will require constant

pressure to keep door moving.

- Close control will only require

momentary contact.

DO NOT add unless using an

entrapment Protection device.

11

9

8

4

7

OPEN AND CLOSE CONTROL OPTIONS

IMPORTANT NOTE:

WHEN STOP BUTTON IS NOT USED, ADD A JUMPER FROM

TERMINAL 3 TO TERMINAL 5.

3

5

MAXIMUM RUN TIME:

1 - ON: Maximum run time is 90 seconds.

OFF: Maximum run time is 45 seconds.

MAXIMUM RUN TIME:

2 - ON: CLOSE limit switch B

OFF: CLOSE limit switch A

MAXIMUM RUN TIME:

3 - OFF: (DO NOT ADJUST)

4 - OFF: (DO NOT ADJUST)

CONSULT FACTORY FOR ADJUSTEMENT

SWITCH #1 SETTINGS

SWITCH #2 SETTINGS

TIMER TO CLOSE SWITCH SETTING:

O = ON F = OFF

1 2 3 4

O O O O

F O O O

O F O O

F F O O

O O F O

F O F O

O F F O

F F F O

1 2 3 4

O O O F

F O O F

O F O F

F F O F

O O F F

F O F F

O F F F

F F F F

= Disabled

= 2 sec

= 3 sec

= 13 sec

= 15 sec

= 23 sec

= 32.5 sec

= 43.6 sec

= 72 sec

= 88 sec

= 107 sec

= 126sec

= 148 sec

= 172 sec

= 198 sec

= 224 sec

SETTING

SETTING

TIME

TIME

SWITCH ADJUSTMENTS

OR

OR

Use SAE 30 Oil (Never use grease or silicone spray).

Repeat ALL procedures.

Do not lubricate motor. Motor bearings are rated for continuous operation.

Inspect and service whenever a malfunction is observed or suspected.

CAUTION: BEFORE SERVICING, ALWAYS DISCONNECT OPERATOR FROM POWER SUPPLY.

Check at the intervals listed in the following chart.

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION

SPANS AMERICA

INSTALLATION AND SERVICE INFORMATION

ARE AVAILABLE 6 DAYS A WEEK

CALL OUR TOLL FREE NUMBER - 1-800-528-2806

HOURS 7:00 TO 3:30 p.m. (Mountain Std. Time)

MONDAY Through SATURDAY

WHEN ORDERING REPAIR PARTS

PLEASE SUPPLY THE FOLLOWING INFORMATION:

PART NUMBER DESCRIPTION MODEL NUMBER

ADDRESS ORDER TO:

THE CHAMBERLAIN GROUP, INC.

Electronic Parts & Service Dept.

2301 N. Forbes Blvd., Suite 104

Tucson, AZ 85745

EVERY

EVERY

EVERY

ITEM

PROCEDURE

3 MONTHS

6 MONTHS

12 MONTHS

Drive Chain

Check for excessive slack.

Check & adjust as required.

Lubricate.*

Sprockets

Check set screw tightness

Fasteners

Check & tighten as required

Manual Disconnect

Check & Operate

Bearings & Shafts

Check for wear & lubricate

MAINTENANCE SCHEDULE