Jackco Models 66300B User Manual

Page 5

Caution: To prevent personal injury, all inspection, maintenance, and repair

procedures must be performed when the jack is free of load.

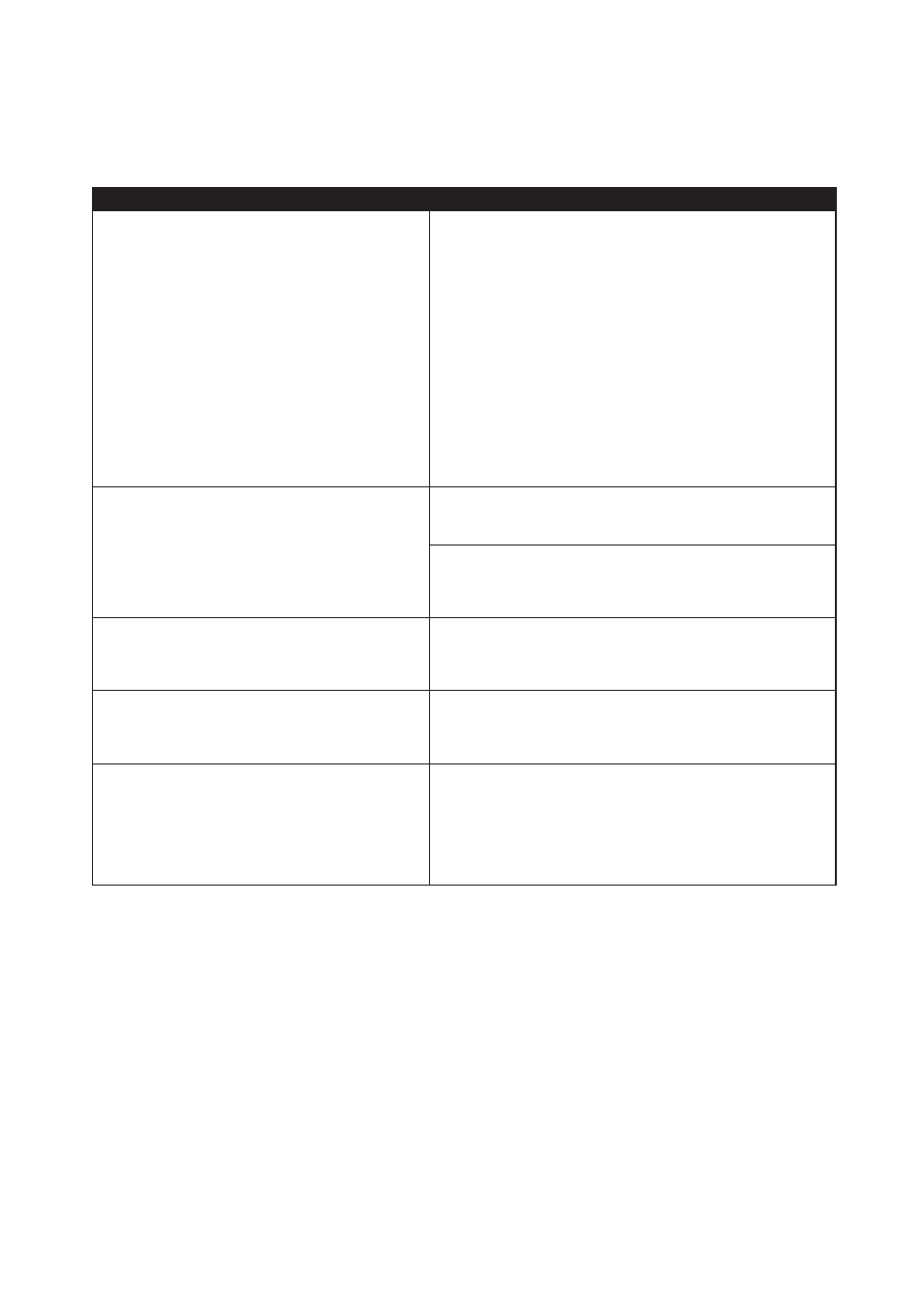

TROUBLESHOOTING

Trouble

Solution

Jack will not lift load or leaks down

excessively

1. The release valve is not closed. Turn the

valve clockwise tightly. If this does not

work, remove handle, lubricate handle

receptacle and handle end, then retry.

2.Low on hydraulic fluid. Follow Step 5 of

the "ASSEMBLY" procedure on page 3.

3.Pump seals or back-up ring may be

defective. Clean hydraulic fluid passages,

replace seals and refill hydraulic fluid.

(Must be serviced by qualified service

center

Jack will not lift to its full height

1.Low on hydraulic fluid. Follow Step 5 of

the "ASSEMBLY" procedure on page 3.

2.The hydraulic system has trapped air.

Follow Step 5 of the "ASSEMBLY"

procedure on page 3.

Jack will not lower completely

Return spring is broken or linkages are

binding. Replace spring if broken. Grease

pivot shaft and all lift arm linkages.

Jack will not lift smoothly or jack

feels spongy

The hydraulic system has trapped air.

Follow Step 5 of the "ASSEMBLY"

procedure on page 3.

Jack will not hold load or handle

rises

Discharge ball is not sealing hydraulic

system and oil may be dirty. Manually flush

hydraulic system. Open the release valve,

as required, to raise and lower the lift arm.

Manually raise and lower lift arm.

5