Venting – HTP 399M User Manual

Page 13

13

D. EXHAUST VENT AND INTAKE AIR PIPE

SIZING

1.

For the 399M the exhaust vent and air intake

pipes should be 4" Schedule 40 or 80.

2.

The total combined equivalent length of

exhaust vent and intake air pipe should not

exceed 85 feet.

a. The equivalent length of elbows, tees, and

other fittings are listed in the Friction Loss

Table 4.1.

b. For example: If the exhaust vent has two 90°

elbows and 10 feet of PVC pipe we will cal-

culate:

Exhaust Vent Pipe Equivalent Length = (2x5)+10=20 feet

Further, if the intake air pipe has two 90°

elbows, one 45° elbow and 10 feet of PVC

pipe, the following calculation applies:

Air Intake Pipe Equivalent Length = (2x5)+3+10=23 feet

Finally, if a concentric vent kit is used we

find:

Total Combined Equivalent Length = 20+23+3=46 feet

Therefore, the total combined equivalent

length is 46 feet which is well below the

maximum of 85 feet.

c. The intake air pipe and the exhaust vent are

intended to penetrate the same wall or roof

of the building.

d. Effort should be made to keep a minimum

difference in equivalent length between the

air intake pipe and the exhaust vent.

4.

The minimum combined equivalent length is

16 equivalent feet.

5.

The maximum combined equivalent length

can be extended by increasing the diameter

of the vent pipe. However, the transitions

should begin a minimum of 15 equivalent feet

from the boiler.

a. Transitions should always be made in verti-

cal sections of pipe to prevent the conden-

sate from pooling in the vent pipe.

b. Use a 6” x 4” reducing coupling to transition

from the 399M boiler connections to 6”

vent.

c. The maximum equivalent length for the

increased diameter vent pipes is 125 feet.

d. If the transition occurs at a distance greater

than 15 equivalent feet from the boiler, the

maximum equivalent length will be reduced.

See Table 4.2. Standard Vent Pipe is 4" and

Oversized Vent Pipe is 6" for the 399M.

E. EXHAUST VENT AND AIR INTAKE PIPE

INSTALLATION

1.

On the 399M Boiler the 4" exhaust vent con-

nection is located at the rear of the boiler and

the air intake is higher and toward the left side

when the boiler is viewed from the front. The

air intake connection is intended for a slip fit.

No sealant or adhesive is required.

2.

Use only solid PVC, CPVC, or ABS schedule

40 or 80 pipe. FOAM CORE PIPING IS NOT

APPROVED.

3.

Remove all burrs and debris from joints and

fittings.

4.

All joints must be properly cleaned, primed,

and cemented. Use only cement and primer

approved for use with the pipe material.

Cement must conform to ASTM D2564 for

PVC or CPVC pipe and ASTM D2235 for ABS

pipe.

VENTING

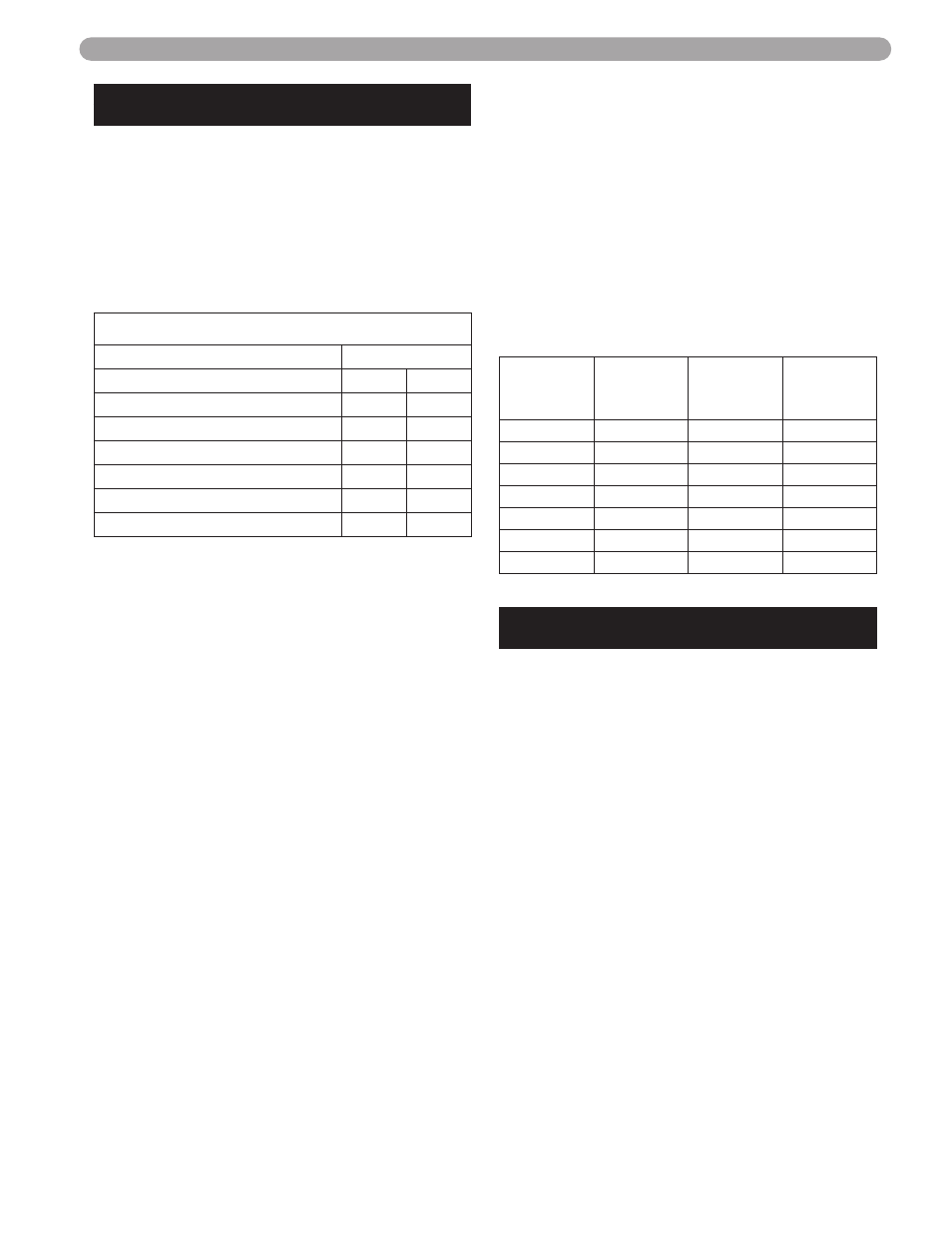

Transition

Point

(ft from

boiler

TEL of

Standard 2"

or 3" Vent

Pipe (ft)

TEL of

Oversized 3"

or 4" Vent

Pipe (ft)

Maximum

TEL of all

Vent Pipe (ft)

15

30

95

125

20

40

77-1/2

117-1/2

25

50

60-1/2

110-1/2

30

60

43

103

35

70

26

96

40

80

8-1/2

88-1/2

None

85

0

85

FRICTION LOSS EQUIVALENT IN PIPING AND FITTINGS

FITTINGS OR PIPING

EQUIVALENT FEET

4"

6"

90 DEGREE ELBOW*

3'

1'

45 DEGREE ELBOW

1'

1'

COUPLING

0'

0'

AIR INLET TEE

0'

0'

STRAIGHT PIPE

1'

0.5'

V2000 4" VENT KIT

1'

N/A

Table 4.2: Vent Termination Kits

Table 4.1

TEL = Total Equivalent Length

*Friction loss for long radius elbow is 1 foot less