Gas & vapour sampling, Sorbent tube features, Sorbent break through – SKC Limited AirChek 3000 Deluxe Pump Step By Step Guide User Manual

Page 15

www.skcltd.com

224-G1 Issue D

Page 13

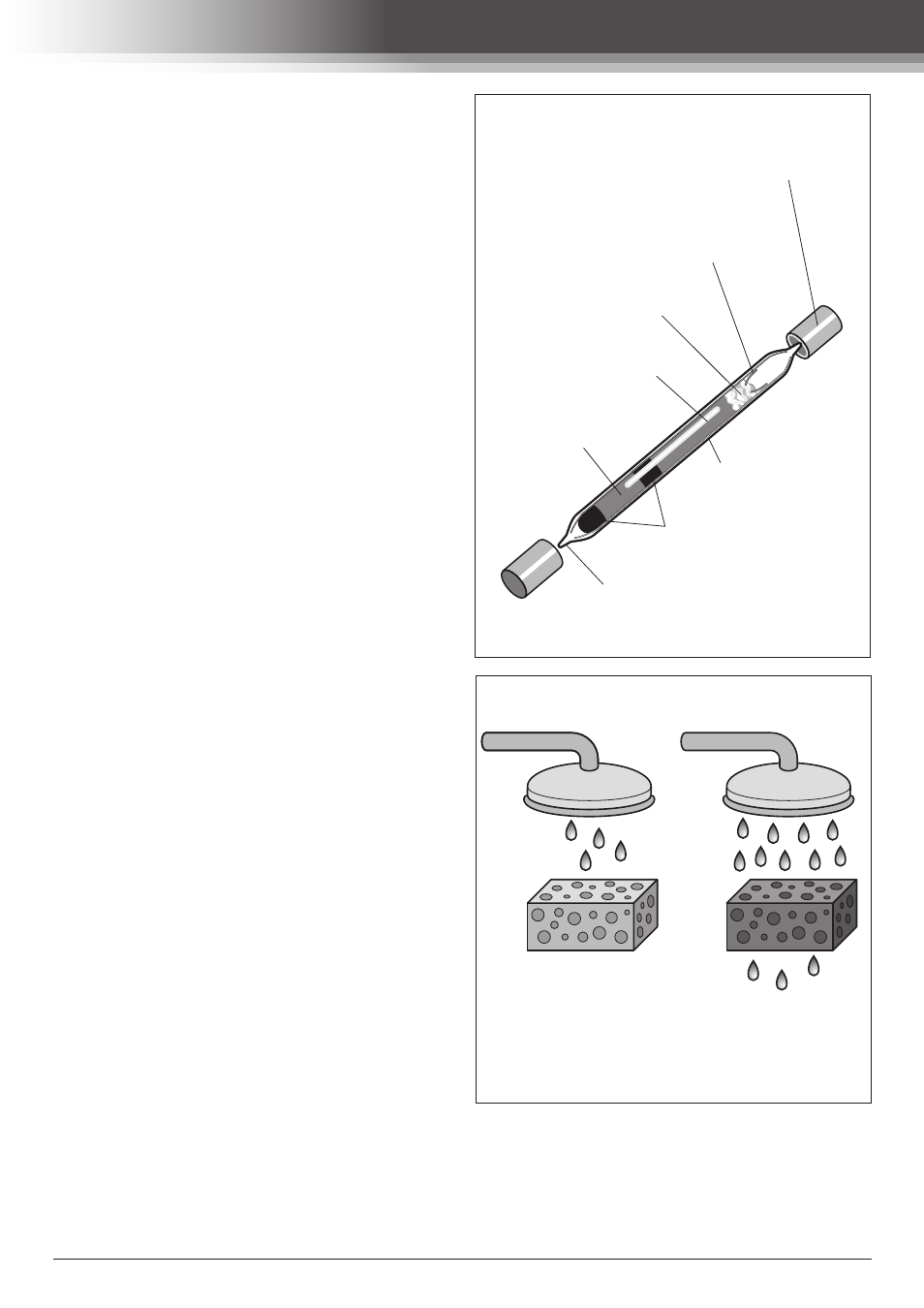

Sorbent Tube Features

Gas & Vapour Sampling

To sample for gases or vapours, especially for

longer periods such as 8 hour TWA, the use

of sorbent tubes is a widely accepted method.

A Sorbent is like a sponge, which soaks up

the molecules of the material being sampled

(which can subsequently be extracted and

analysed). Activated charcoal is the most

commonly used material but it cannot adsorb

every substance, which is why other materials

such as Silica Gel and Tenax are often used.

Once the pollutant has been trapped by a

sorbent tube it then needs to be removed for

analysis. This is achieved using either a solvent

wash or heat, which drives the collected

chemicals off the sorbent and into an analytical

instrument such as a Gas Chromatograph.

Most tubes have two layers of sorbent in them,

the smallest of which (usually situated nearest

the pump) is known as the backup. Analysis

of the backup sorbent reveals whether

breakthrough has occurred (see figure below).

Breakthrough occurs when the main layer of

sorbent (nearest the open end of the tube)

has become flooded with the contaminant

chemicals which then overflow into the backup

layer.

Gas is sampled in one of the two following

ways using a sorbent:

1. Active sampling using pumps and tubes.

2. Passive (or Diffusive) sampling using

badges.

There are many different types of sorbents

and an even larger number of different sorbent

tubes. Each tube is designed and validated

for a specific substance. Sorbent tubes vary

in size from the Standard Charcoal Tube (6 x

70mm) to ''Jumbo Tubes'' (10mm x 110mm)

and they have different separators between

the sorbent beds.

NIOSH approved sealing caps

prevent contamination

High purity glass wool

precise amount for uniform

pressure drop

Glass tube

drawn to very close tolerances

for repeatable results

Backup sorbent layer

detects sample breakthrough

Precision lockspring

holds sorbent layers securely

in place to prevent sample

channeling; allows transporting

without damaging sample

(patented)

Sorbent layer

precisely controlled surface

area, pore size, adsorptive

characteristics, particle size

Foam separator

for uniform pressure drop

Precision sealed tips

permit safe, easy breaking to the

specified opening size

Contaminant

saturates sorbent

leading to

break through

Sorbent Break Through

All contaminant

adsorbed by

sorbent