Maintenance, Troubleshooting guide, Inspecting and clean- ing the applicator – Ransburg RPA-2 Powder Applicator A12950-XXX User Manual

Page 20: Rpa-2 powder applicator - maintenance

RPA-2 POWDER APPLICATOR - Maintenance

17

LN-9271-12.2

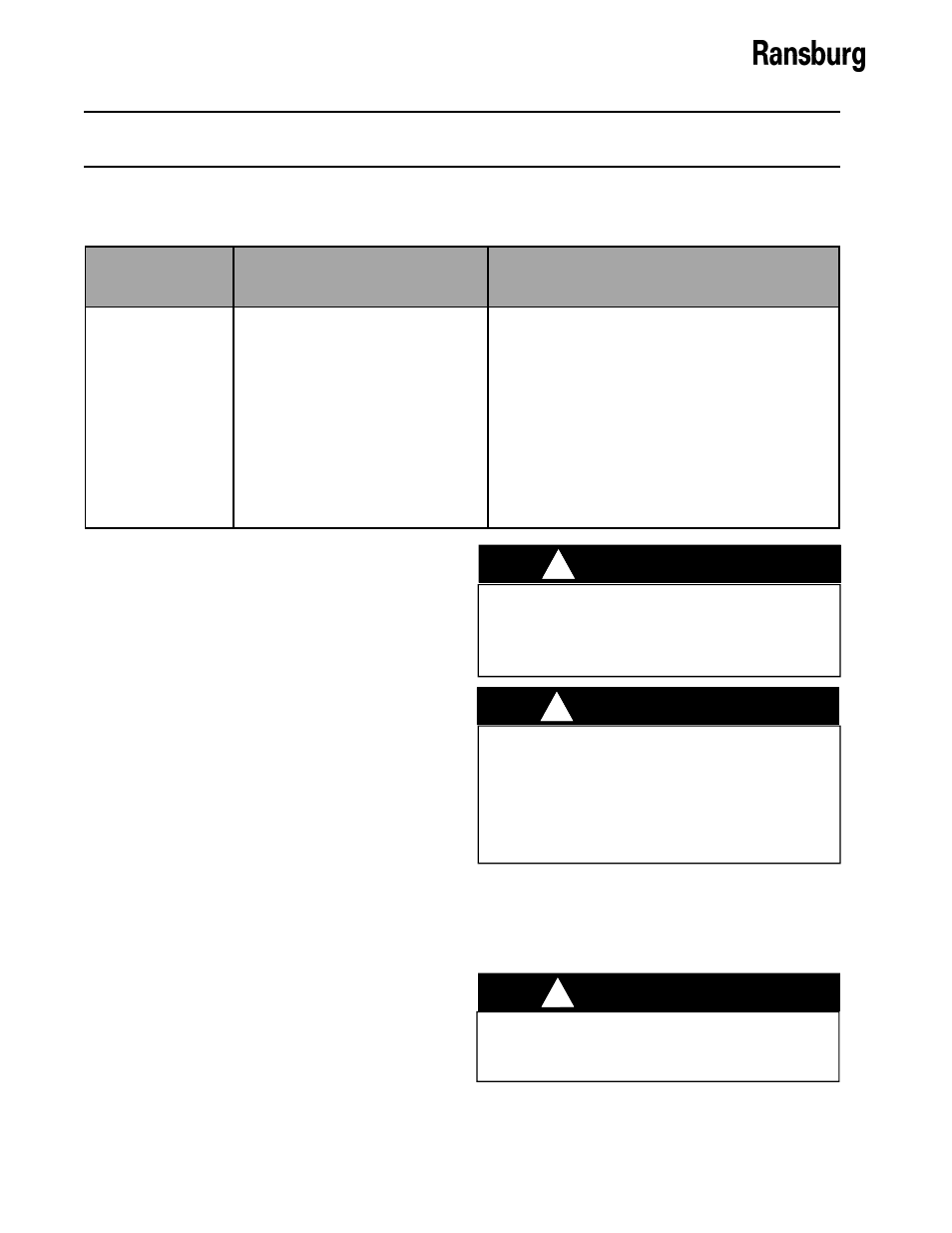

General Problem Possible Cause

Solution

Applicator sprays

powder, high volt-

age available, but

the powder does

not adhere on the

work piece.

1. High voltage too low

2. Work piece not properly

grounded

1. Increase high voltage on the control unit.

2. Check the grounding/measure

3. Look for loose connections

•

Plastic on conductive component

•

Loose fitting hinges

•

Non-conductive coating present on sub-

strate before spraying.

MAINTENANCE

TROUBLESHOOTING GUIDE

!

W A R N I N G

Be careful with nozzle electrode during

cleaning and maintenance— danger of inju-

ry! Never bend or pull electrode

Before cleaning applicator. switch off the

control unit. The compressed air used for

cleaning must be free of oil, water and other

contaminates.

!

W A R N I N G

!

W A R N I N G

Make sure the large diameter threaded

ring (applicator body to shaping ring) is al-

ways tightened well. If it is fitted loosely,

there is a danger that a discharge may occur

with the high voltage, which leads inevitably

to damaging the plastic components.

INSPECTING AND CLEAN-

ING THE APPLICATOR

1. Blow off the atomizer externally with com-

pressed air.

2. If a solvent wipe is required, use VM&P

Naphtha for a final wipe to remove any con-

ductive residue.

3. Clean the atomizer only with a damp rag.

Never immerse the components into sol-

vents.

4. Remove any impact fusion on deflector

without scratching or scoring the soft plastic

surface of the deflector. Impact fusion can

be removed with a solvent soaked towel.

5. If impact fusion is not removed, it will short-

en the life of the parts and cause defects

6. Blow out all powder hoses with high

volume/high velocity air purge during clean-

ing.