Maintenance schedule – Finish Thompson CQC2 User Manual

Page 9

9

MAINTENANCE SCHEDULE

EVERY USE:

CLEANUP ANY SPILLS - Antifreeze/coolants can be corrosive to the unit’s painted finish. Thoroughly wipe, rinse and

dry any spills immediately.

AS REQUIRED:

FLUSH THE EVACUATION PUMP - Dirt and grit from waste coolant can cause premature wear on the Evacuation

Pump’s impeller. Periodically flush the pump by pumping 5 gallons of cool, clean water through the RED hose.

REPLACE PUMP IMPELLER - If loss of pump performance is noticed due to pump being run dry, wear or damage

from foreign objects, replace impeller.

1.

Disconnect power, Remove the CQC2’s rear panel.

2.

Remove cover plage from the pump head (held in place with four Phillips head screws).

3.

Pull out old impeller.

4.

Lubricate the new impeller with petroleum jelly.

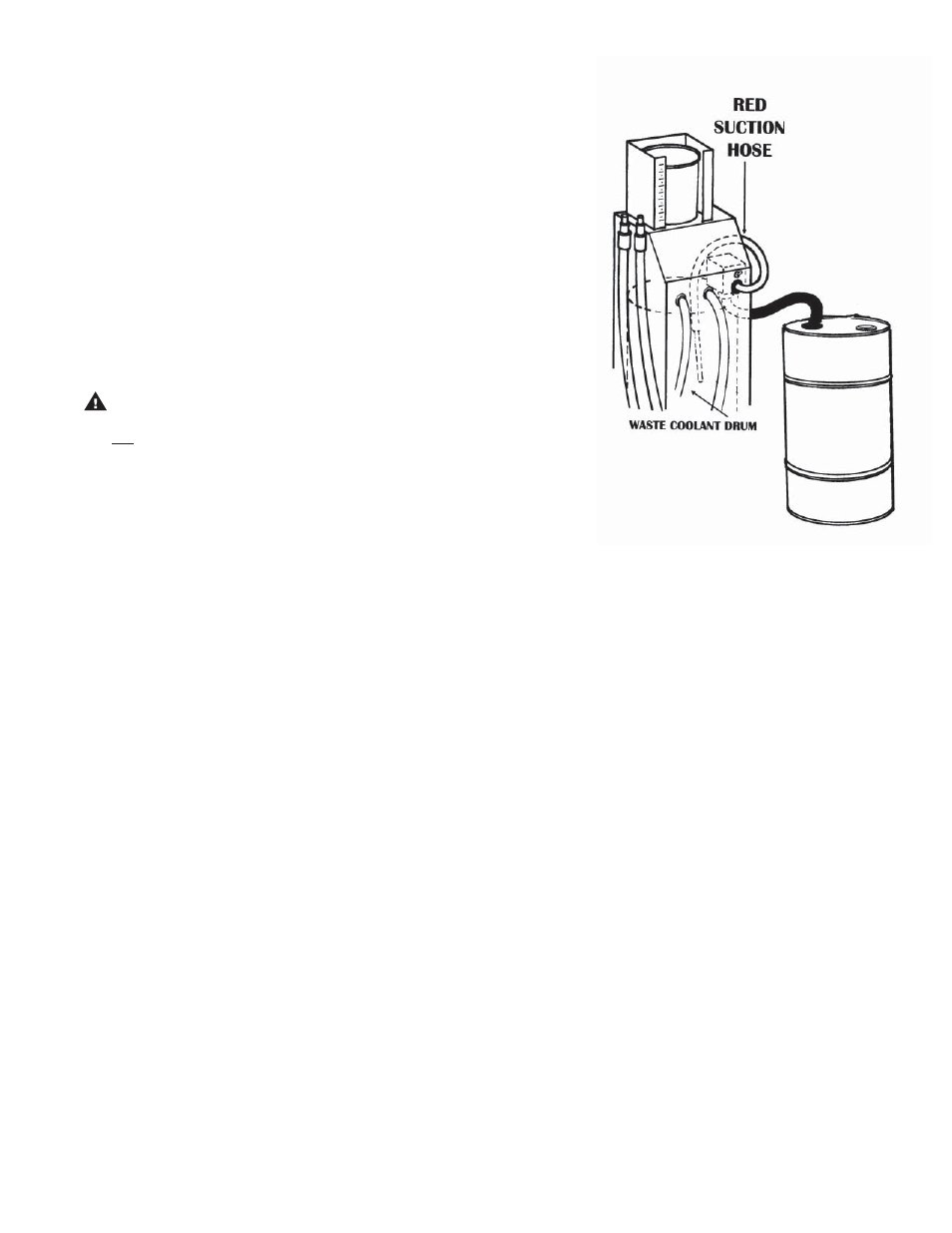

DRAINING THE WASTE COOLANT DRUM:

1.

Remove the BLACK hose from the large opening of the waste

coolant drum (located in the back of the machine) and place it into a

receiving container.

2.

Insert the wand from the RED hose into the large opening on the

waste coolant drum until it reaches the bottom.

3.

Turn ON the evacuation pump (switch located on the front bevel of

the unit).

4.

Allow the pump to run until all liquid is removed from the waste

coolant drum.

5.

Turn OFF the evacuation pump and return BLACK and RED hoses

to their original positions.

CAUTION: Never allow the pump to operate without liquid. Running

the pump dry will cause premature wear or damage the pump and is

not covered under warranty.