A.O. Smith BTH 300A User Manual

Page 24

24

To dissolve and remove the more stubborn mineral deposits,

A.O. Smith UN•LIME ® Professional Delimer should be used.

NOTE: UN•LIME is not available in Canada. Please call Customer

Service at 1-800-265-8520 for approved alternatives.

A.O. Smith UN•LIME® Professional Delimer is an easy to handle

patented food grade acid formulated specifically for lime scale

removal from all types of water using equipment. Available in

1 gallon (3.8L) (part no. 4763) and 5 gallon (19L) (part no. 4813)

sizes. Hydrochloric base acids are not recommended for use on

glass-lined tanks.

A.O. Smith Form No. 4800 Rev. 8, entitled “Why, When and How”,

describes tank cleaning methods and materials. UN•LIME and

the booklet may be obtained through your A.O. Smith dealer or

distributor.

The cleanout opening is shown in Figure 24. To clean heater

through cleanout opening, proceed as follow:

1. Turn off water inlet valve, the heater electrical disconnect switch

and open drain valve.

2. Remove outer cover plate from lower side of heater jacket.

3. Remove cover from cleanout opening.

4. Remove lime, scale or sediment using care not to damage

the glass-lining.

5. Inspect cleanout plate gasket: If new gasket is required, replace

with A. O. Smith part no. 99038.

6. Install cleanout plate. Be sure to draw plate up tight by

tightening screws securely.

7. Close drain valve, open water inlet line and turn on the power

burner electrical disconnect switch.

8. Check for water leakage.

9. Replace outer jacket cover plate.

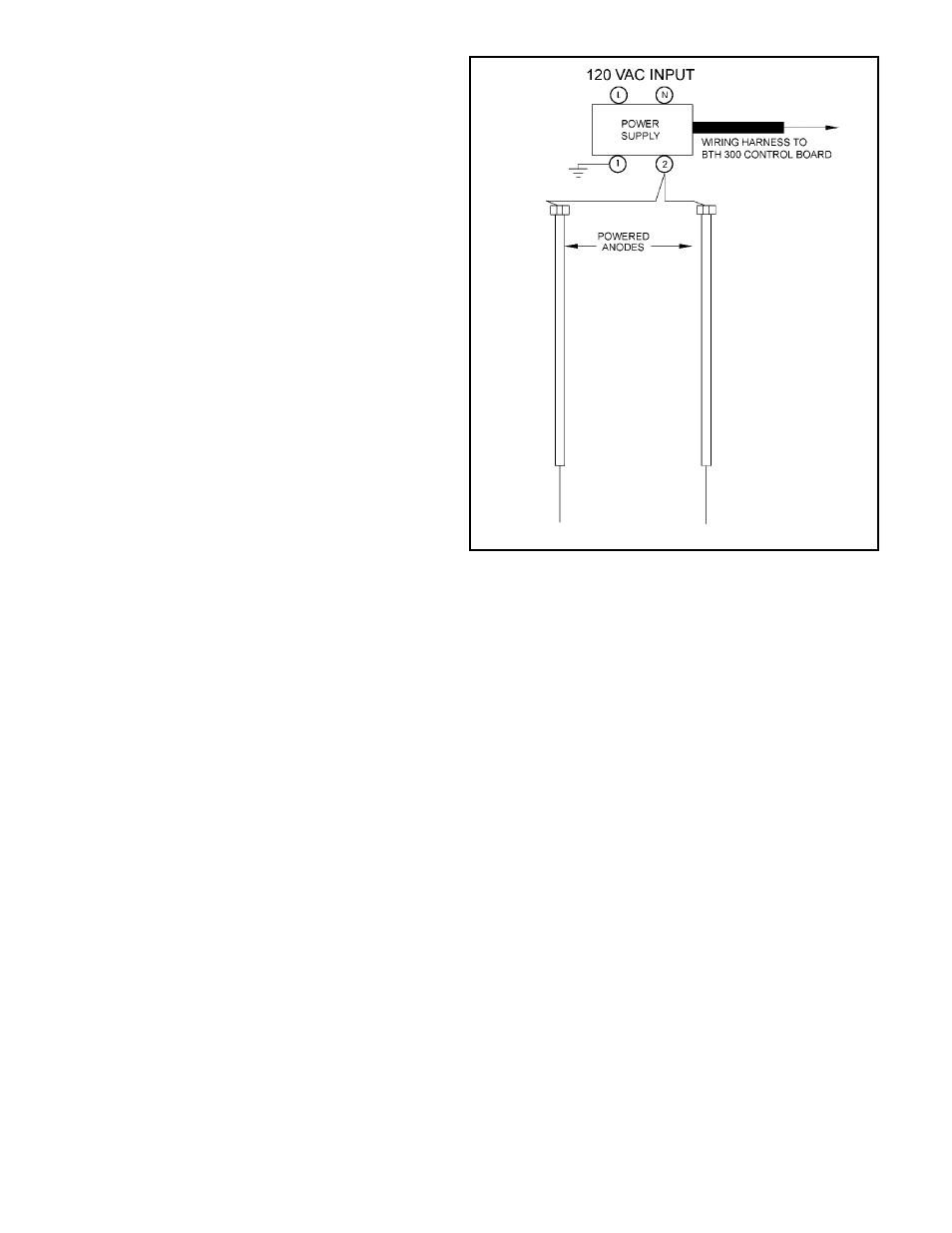

POWERED ANODE SYSTEM

The BTH-300 & 400 are factory equipped with a powered anode

system. The anodes are of a permanent design and do not need

replacing unless damaged.

POWERED ANODE OPERATION

To insure a long, trouble-free operating life, the BTH-300 & 400

are equipped with a powered anode system consisting of:

1.

A power supply with a built-in diagnostic LED.

2.

Two titanium anodes.

3.

Wiring harness with ground lead.

Replacement parts for this system may be ordered from A.O.

Smith Product Service Division; see BTH-300 & 400 parts list for

specific details.

FIGURE 25.

POWER SUPPLY LED MEANINGS:

The power supply diagnostic LED is located in the bottom right-

hand corner of the BTH-300 & 400 control board.

Steady green light means powered anode system is functioning normally.

No light means no line voltage or a defective power supply.

Flashing red light can mean (1) the heater has no water or

(2) a broken or loose connection has occurred.

DRAIN VALVE AND ACCESS PANELS

The heaters are equipped with a 3/4" drain valve.

An access panel covers the cleanout opening in the tank which is

sealed by a gasket and cover, see Figure 24.

RELIEF VALVE

At least twice a year, the temperature and pressure relief valve

should be checked to ensure that it is in operating condition. To

check the relief valve, lift the lever at the end of the valve several

times. The valve should seat properly and operate freely.

If water does not flow, remove and inspect for obstructions or

corrosion. Replace with a new valve of the recommended size as

necessary. Inspection of the valve should be performed at least

every three years. Do not attempt to repair the valve, as this could

result in improper operation and a tank explosion. In areas with

poor water conditions, it may be necessary to inspect the

T&P valve more often than every three years.