Installation – Poweramp POWERSTOP A 11.1996 User Manual

Page 9

Installation

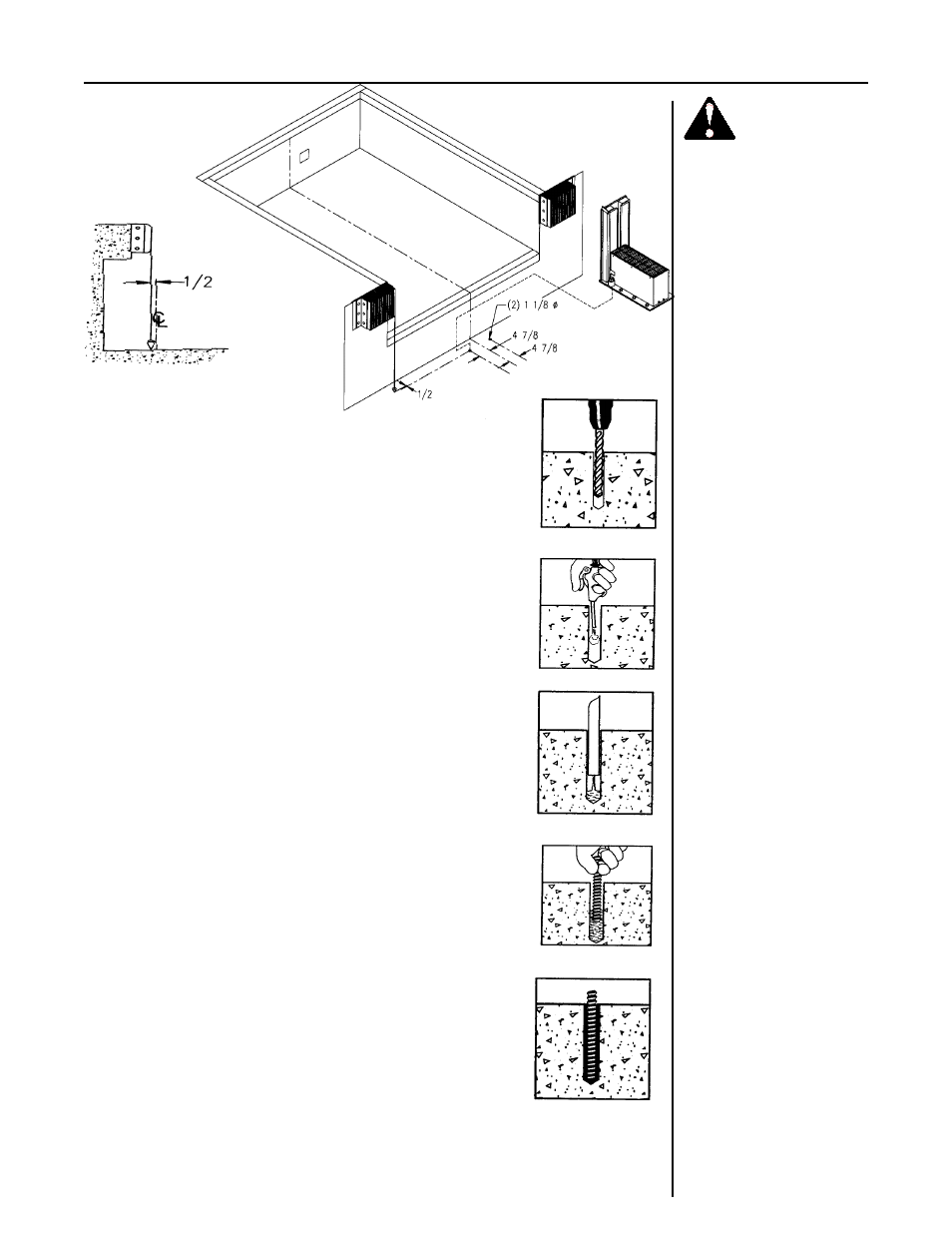

1" Main Anchors

Figure 7

Plumb line

WARNING

Proper safety apparal

should be worn when

installing the truck restraint.

as shown in Figure 7. After locating and marking the

primary anchor locations (qty. 2) on the drive surface, drill

1-1/8" diameter holes 7 to 7-1/2" deep. If drill breaks

through concrete at a depth of less than 6", consult

factory. The remaining (6) 3/4" anchor holes can be

drilled at this time.

4. Preparation of the anchor hole is necessary to assure a

long lasting installation. Prepare the 1-1/8" diameter

holes in the following manner:

A. Blow the hole clean with compressed air, brush out

using 1" nylon brush, blow clean again. Holes

should be clean and sound. They may be dry or

damp, but should be free of standing water or frost.

Be sure rod fits into hole. If larger hole is required,

the diameter should be as close as possible to the

rod diameter.

B. Fill the hole approximately half way with adhesive

mortar starting from the rear of the hole. Slowly

withdraw the nozzle as the hole fills to avoid creating

air pockets within the hole.

C. Push the threaded rod into the hole while turning

slightly to insure positive distribution of the adhesive

mortar. Be sure rod is fully seated at the bottom of

the hole and that the mortar has flowed from the top

of the hole. If an insufficient amount of adhesive is

placed in the hole, indicated by a lack of filling to the

top of the hole when the rod is inserted, the rod must

be extracted, additional adhesive added and rod

reinserted. The threaded rod used must be free of

dirt, grease, oil or other foreign material. Allow the

adhesive mortar to cure for the time specified in chart

prior to applying any load. See Figure 10. Do not

Figure 8

6