Adjustment and testing, Testing powerhook operating range – Poweramp POWERHOOK P4111-0010 5.2006 User Manual

Page 30

28

4111-0010 — December 2004

NOTE: Test operating range of PowerHook without

truck/trailer backed into dock.

1. Make sure the selector switch is in Normal and

BYPASS mode has not been activated.

-Red Inside Light, No Amber Light

-Green Outside Light

2. Momentarily press the ENGAGE button. Hook

should lower, fully extend, fully raise, partially

retract, lower, and then fully retract.

-Inside Amber Light for 30 seconds, then Red

*Alarm will sound if equipped

-Outside Red Light for 30 seconds, then Green

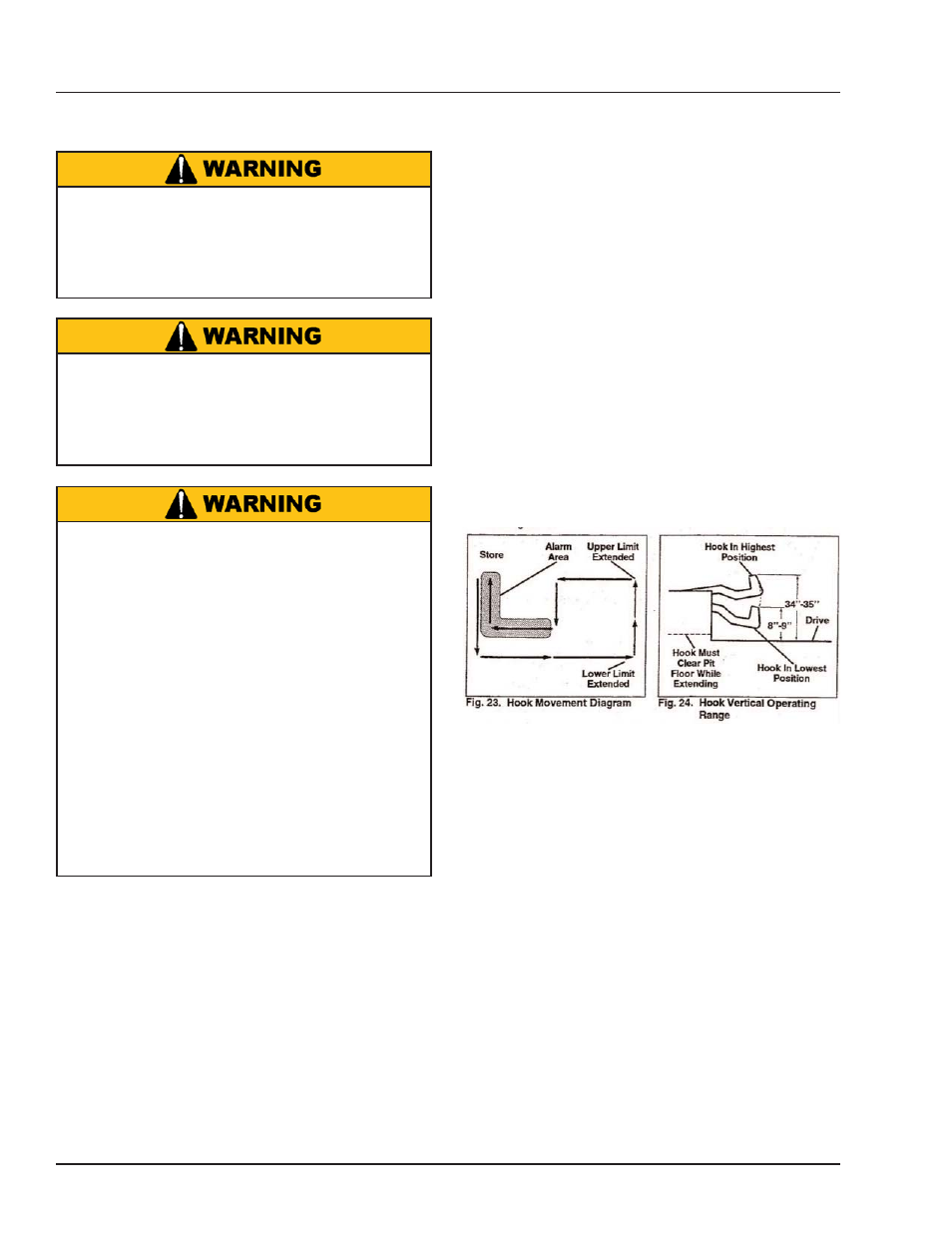

1. Measure upper and lower limits of operating

range. The upper and lower limits of the vertical

operating range should be 30”-35” and 8”-9”

respectively (Application Dependent).

Testing PowerHook Operating Range

ADJUSTMENT AND TESTING

Follow the installation instructions found in

the PowerHook Installation & Operation

Manual prior to attempting any adjustments.

With the PowerHook installed in the hook

pan and power supplied to the pump/motor,

proceed with the PowerHook adjustments.

NOTE: Hook cannot be stopped while cycling.

Obtain measurements by placing tape measure next

to the moving hook.

IMPORTANT: The upper and lower limits of the

operating range will vary with application pit depth.

These limits may not be attainable if variations in

dock height and/or pit depth exist. Consult factory if

this situation occurs.

When service under the dock leveler is required,

always lock all electrical disconnects in the OFF

position after raising the platform and engaging the

maintenance prop. Failure to do this may result in

serious personal injury or death.

Always post safety warnings and barricade the

work area at dock level and ground level to prevent

unauthorized use of the dock leveler before

maintenance is complete. Failure to do this may

result in serious personal injury or death.

Always stand clear of the dock leveler lip when

working in front of the dock leveler.

The maintenance prop MUST be in the service

position when working under the dock leveler. For

maximum protection, use an OSHA approved

locking device to lock the maintenance prop in the

service position. Only the person servicing the

equipment should have the key to unlock the

maintenance prop.

Unless the dock leveler is equipped with a tethered

remote, two people are required to engage the

maintenance prop: one person to operate the unit,

the other person to engage the maintenance prop.

Failure to follow these instructions may result in

serious personal injury or death.