Perma pure llc – Perma Pure Baldwin-Series M5 User Manual

Page 4

PERMA PURE LLC

Model M5 User’s Manual

Doc. #580: Revision: 000

Page 4 of 22

General description

The Perma Pure/Baldwin Tester’s Choice Model M5 Thermo-Electric cooler features a complete gas

conditioning system in one easy to manage enclosure. The unique design leaves additional space to

install or access other sample conditioning system components. A unique drop-down door on the

M5 cooler section, provides easy access to electronic boards and the power supply. All electronic

boards (control, relay, and display) are mounted on the door of the cooler for easy access. Sample

pump and peristaltic drain pump(s) are also mounted within the enclosure.

The process of sampling combustion

product stack gas or exhaust from internal

combustion engines requires a method to

remove the moisture from the sample,

without removing the gas components of

interest. The Tester’s Choice M5 System is

an ideal way to decrease the dew point of

combustion gases to a repeatable, stable,

constant low dew point. The Tester’s Choice

M5 system prevents water condensation in

sample pre-filters, sample pumps, and gas

analyzers. For gas analyzers where water

vapor is an interferent, a stable, repeatable,

dew point, becomes a part of the gas

analyzer performance specification. The

Tester’s Choice system provides this

constant low water concentration, resulting

in an accurate component gas

measurement.

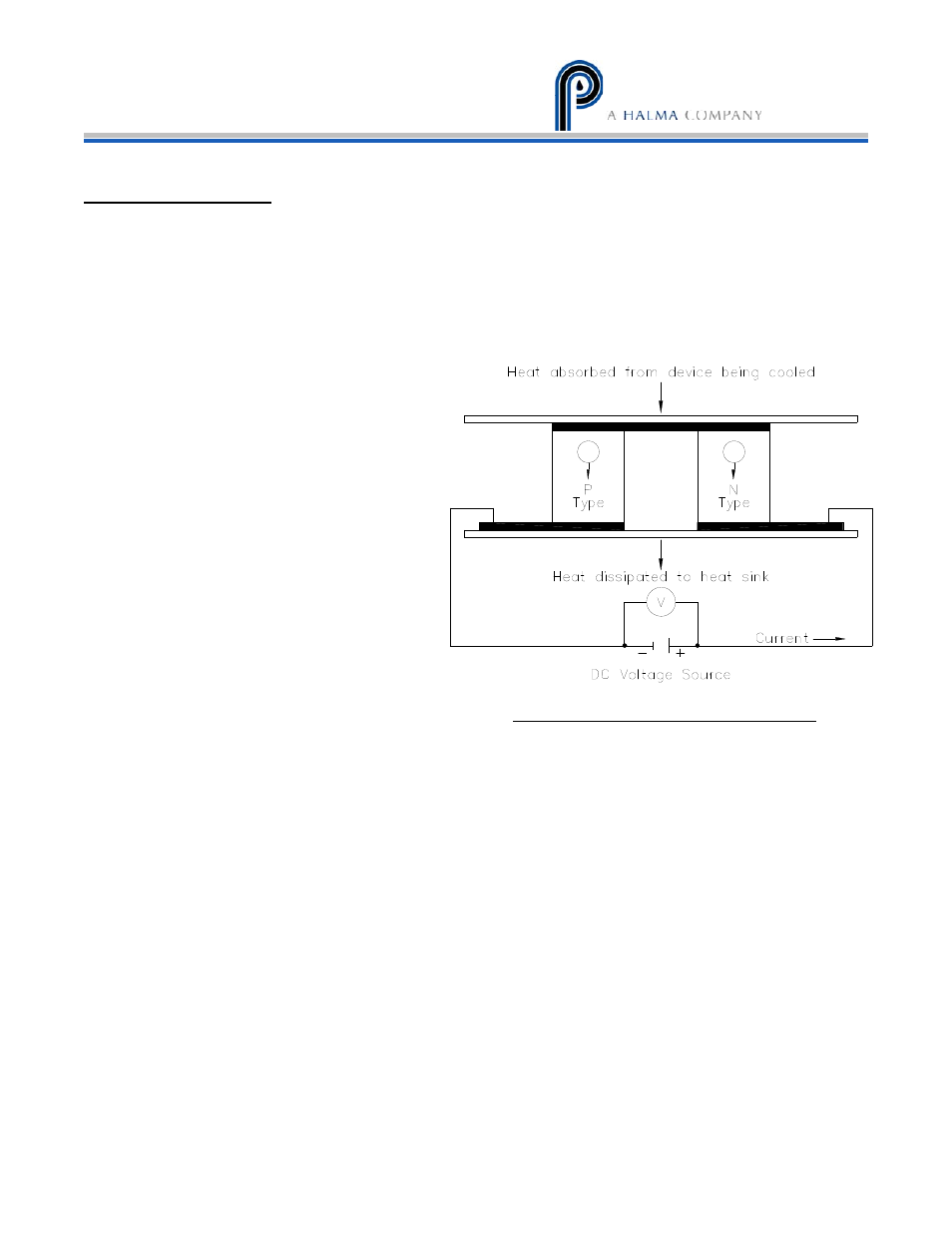

The Tester’s Choice M5 system removes the moisture from the sample gas by cooling the gas as it

passes through a laminar impinger (heat exchanger). A diagram showing the gas flow path through

an impinger is shown in the Appendix B2. The impinger, made of 316L stainless steel, Durinert

®

(a

corrosion-resistant inert coating over 316L stainless steel), PVDF (Kynar®), or glass, is mounted

within a thermally insulated heat transfer block bored to receive the impinger without a mechanical

lock. This assembly allows the easy removal of any impinger simply by slipping it out of the cooling

block by hand. The heat transfer block cools the heat exchanger through the heat pumping action

of the Peltier element. The heat transfer block is on the cold side of the thermo-electric element

and the heat sink is on the hot side of the thermo-electric element. The desired temperature is

maintained by a closed loop control system, which is implemented through an analog proportional

controller. The controller uses a type K thermocouple as a sensor.

Figure 1: Thermo-electric element (Peltier)