Filter specifications installation, Replacing filter element, Performance – Perma Pure FF-250-Series Filter User Manual

Page 2: Part numbers for replacement

PRESSURE DROP vs. FLOW

0

10

20

30

40

50

60

70

80

90

0

5

10

15

20

25

FLOWRATE, LPM OF AIR, 0 PSIG

PRE

S

S

URE

DR

O

P

,

I

N

CHE

S O

F

W

A

T

E

R CO

LU

M

N

Description

Specification

Top and Bottom Materials

316 SST or Kynar®

Shell Material

Borosilicate Glass or 316 SST

Maximum Temperature

Shell: Kynar 120°C, SST 230°C

Maximum Pressure

30 PSIG

Dimensions

2.5" dia. X 4.0" h

Inlet, Outlet and Drain Ports 1/8" NPT Female

Center Bolt

1/4-20 x 3.25", Hastelloy® C276

FILTER SPECIFICATIONS

INSTALLATION

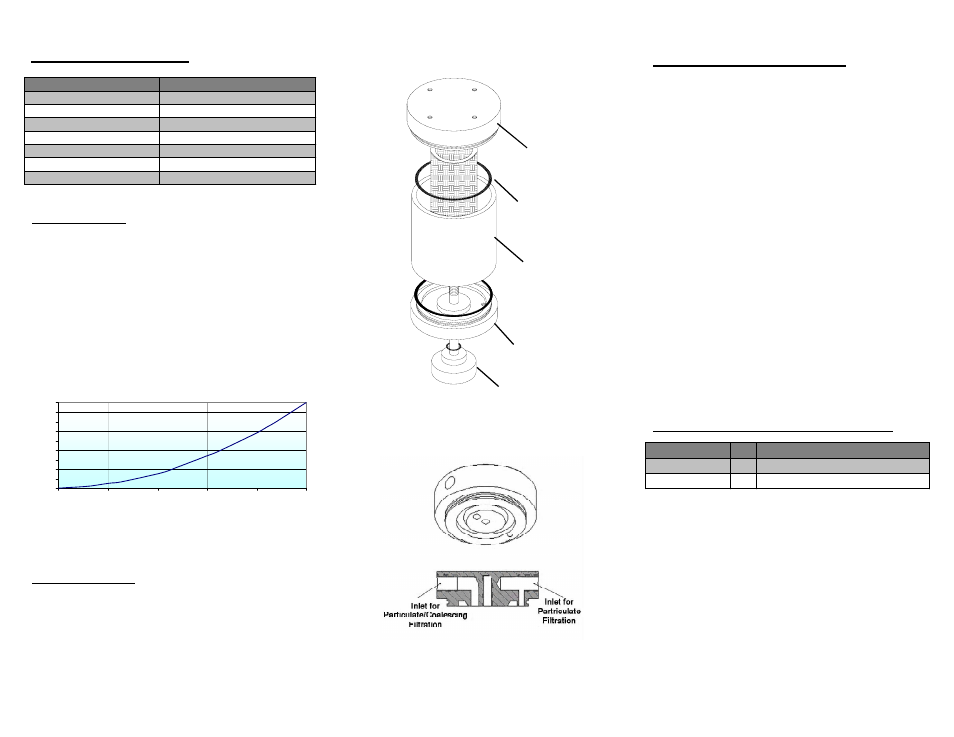

Figure 2 - Pressure Drop Curve

All ports are 1/8” NPT female. To use filter as a

particulate filter, connect sample to port aligned

with hole on underside of top cap. (Refer to

Figure 4)

To use as a coalescer, have sample flow inside

filter element by connecting sample inlet to other

port.

REPLACING FILTER ELEMENT

Figure 3 - Exploded View

PERFORMANCE

FF-250 filters will remove liquid droplets and

particles down to 0.1 micron with an efficiency of

95% or greater.

PART NUMBERS FOR REPLACEMENT

Bolt

Bottom Cap

Shell

Top Cap

O-ring

FF-250 filter should be checked regularly to ensure

element is in good condition. If filter element

appears to be dirty or begins to cause flow

restriction in system, it should be replaced.

1. Loosen bolt on bottom of filter housing.

2. Pull assembly apart and remove element.

3. Install glass shell onto bottom piece - a slight

twist may be necessary to get the shell over the

o-ring.

4. Place the new element into grooves in top and

bottom of housing.

5. Assemble top to shell assembly.

6. Make sure the element is seated correctly in top

groove.

7. Replace bolt through bottom piece and screw

into top piece. Tighten just enough so it does not

vibrate loose.

Figure 4 - Top Cap

Part Number Qty Description

FF-250-E-2.5G

1 Replacement Filter Element

FF-250-3

1 Replacement O-Rings, Set of 3