Description of components – Perma Pure ZERO-AIR GENERATOR User Manual

Page 4

3

Form #240

Zero-Air Generator Manual

Rev 11/98

Description of Components

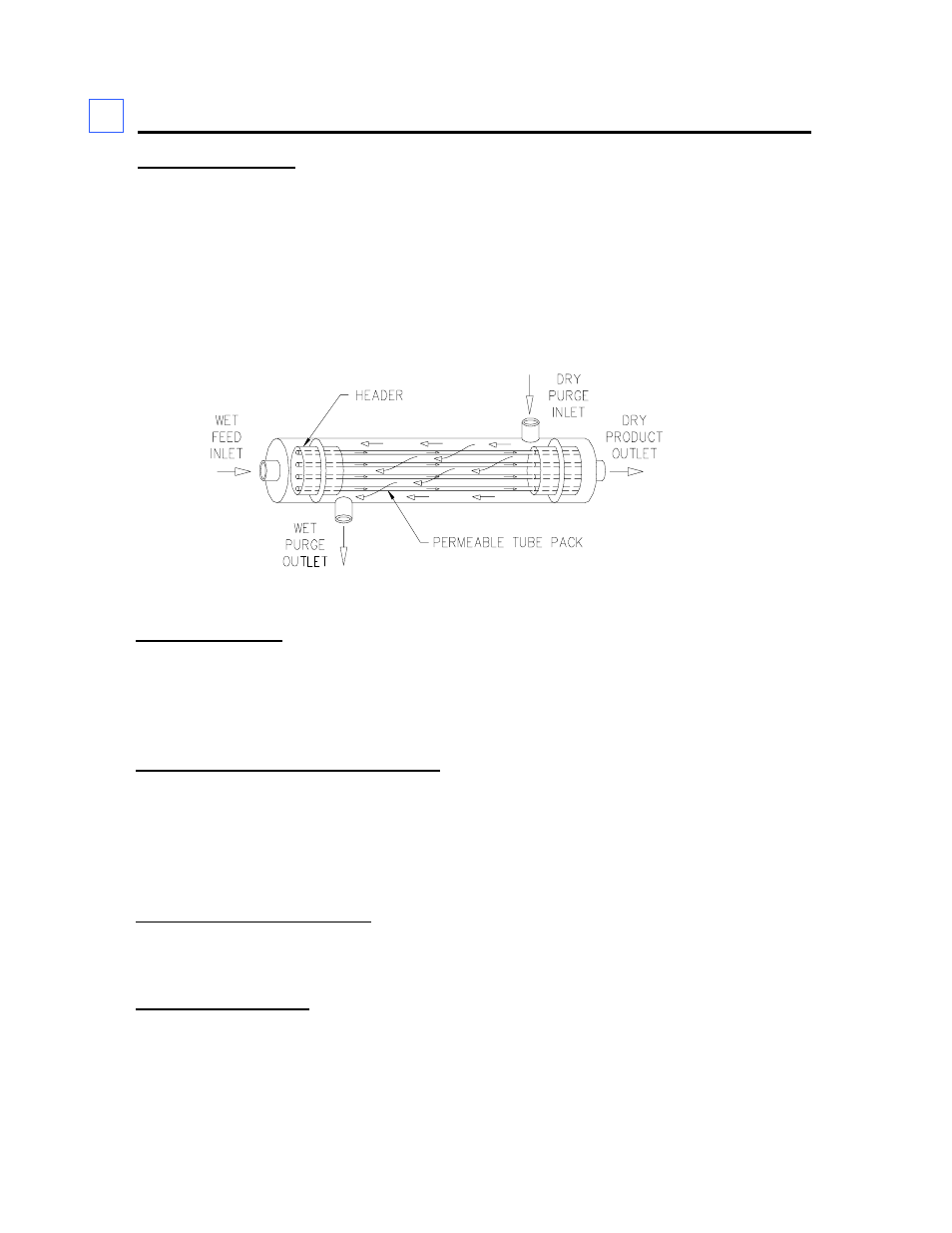

2.1 Perma Pure Dryer

Water vapor and certain polar organic compounds (i.e. alcohols, ketones) are removed

here. A bundle of Nafion

tubes is housed inside the dryer shell. As the wet compressed

air flows through the tubes, the water vapor is absorbed through the membrane and

carried off by a counter-current purge air flow at a reduced pressure. The driving force for

this process, known as permeation distillation, is the difference in partial vapor pressure of

water between the product and purge gas flows. In this system, a portion of the dried air

is expanded and used as the purge gas.

Figure 2 – Perma Pure Nafion Membrane Dryer Schematic

2.2 Ultraviolet Lamp

Used for the destruction of bacteria into carbonaceous by-products. The lamp produces

approximately 1-3 PPM of ozone (O

3

), which then breaks down microorganisms into

carbon compounds that are removed further downstream. The lamp also oxidizes NO to

NO

2

, which is readily removed by system adsorbents.

2.3 Activated Carbon/Alumina Mixture

This is a blend of high performance activated carbon and impregnated alumina pellets.

This mixture will remove trace quantities of chlorine (Cl

2

), hydrogen fluoride (HF),

hydrogen sulfide (H

2

S), nitrogen oxides (NO

x

), ozone (O

3

), sulfur dioxide (SO

2

), sulfur

trioxide (SO

3

), and general hydrocarbons (HC). In addition to removing these substances,

the mixture changes from purple to brown, indicating the need for replacement.

2.4 Carbon Monoxide Catalyst

Palladium impregnated alumina pellets are used to convert low levels of CO to CO

2

. This

catalyst is not consumable, and should last for the lifetime of the unit.

2.5 1

µµµµ

Particulate Filter

The last stage of purification is the particulate filter. This filter has an absolute retention

rating of 1 micron, and a 93% rating for particles down to 0.1 micron. The disposable

filter is housed in a transparent plastic housing, allowing easy visual determination of the

filter’s condition.

2