Perma Pure MD-R Series User Manual

Page 2

(P

s

/2P

v

)

– 1

PRINCIPLE OF OPERATION

NOTE: Pressure units must be in absolute

terms.

For proper operation, be sure that the

pressure ratio, P

s

/P

v

is greater than 2. Vacuum

pump on purge exhaust is optional.

Where:

Vp = Purge flowrate (indicated on flowmeter)

Vs = Sample flowrate (indicated on flowmeter)

Ps = Sample pressure (in absolute units)

Pv = Purge pressure (in absolute units)

V

p

= V

s

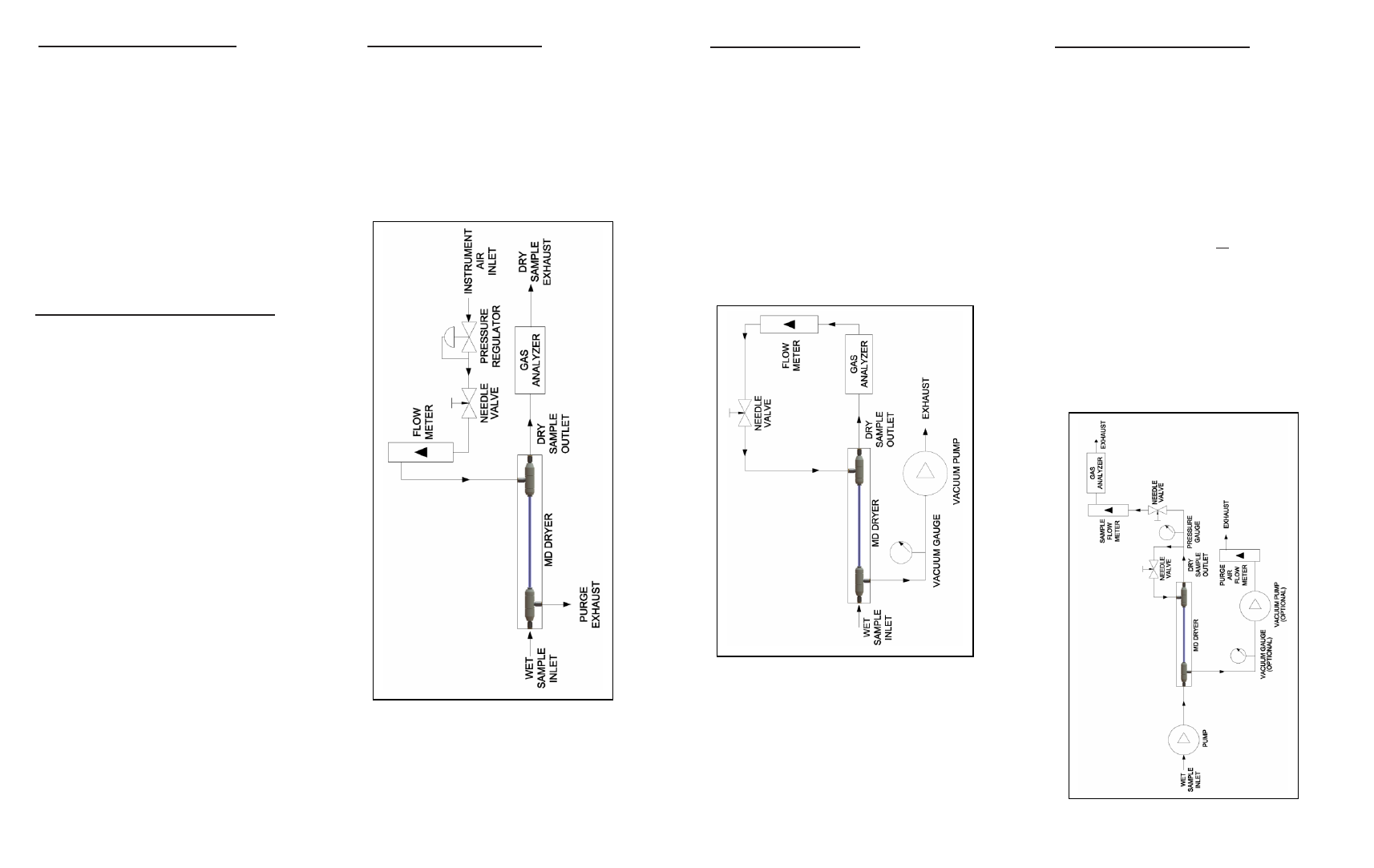

1. STANDARD METHOD

2. REFLUX METHOD

3. SPLIT SAMPLE METHOD

The reflux setup, shown in Figure 2, returns

dry sample gas back to the dryer for use as

the purge after it has gone through the

analyzer. Since this method uses all of the

dry sample gas as the purge gas, only the

sample gas flow required for analysis

passes through the dryer. This results in

high drying efficiency

.

The vacuum on the purge gas should be at

least 15” of Hg, with a higher vacuum

preferable. This vacuum level is necessary

to provide the desired 2:1 purge-to-sample

gas flow ratio.

The split sample method, shown in Figure 3,

diverts some of the sample from the main

stream to be used as the purge gas. More

sample gas passes through the dryer than is

required for the analysis, lowering the drying

efficiency when compared to the reflux

method. The following equation can be used

to determine the purge flow rate required for

the split sample method. Any units may be

used as long as they are consistent.

MD-

R™ Series gas dryers are shell and tube

moisture exchangers that transfer water

vapor between two countercurrent flowing

gas streams. The dryers consist of a Nafion

®

polymer tube surrounded by an outer tube.

Dry purge gas flowing over the exterior

surface of the Nafion tubing continuously ex-

tracts water vapor from the gas stream inside

the tubing. The driving force is the difference

in water concentration on the opposite sides

of the tubing wall. The purge gas then

carries

the water vapor away.

The most efficient way to set up MD-R

Series dryers is to have sample gas enter

through the Nafion tube (wet sample gas

inlet) and purge gas flowing countercurrent

to the sample (refer to Figure 1). Purge

gas should be instrument air or other dry

gas. If no dry purge gas is available, the

reflux or split sample purging method

shown to the right may be used.

INSTALLATION SPECIFICATIONS

When installing MD-R Series gas dryers,

the following rules apply:

1. Sample pressure equal to or greater

than purge pressure.

2. 2. Sample gas pressure not to exceed

80 psig.

3. 3. Temperatures must not exceed

120°C.

4. 4. Purge air of -40°C dew point at a

flow rate of approximately two to times

sample flow is required to achieve

rated performance.

5. Sample and purge air must flow

counter-current to each other.

6. If sample dew point is above ambient

temperature, inlet of dryer must be

heated. Call factory for details.

Figure 1 - Typical Setup

Figure 2 - Reflux Setup

Figure 3

– Split Sample Setup