Troubleshooting, Roubleshooting – Nova-Tech Pulsafeeder OMNI DC2-DC6 User Manual

Page 27

23

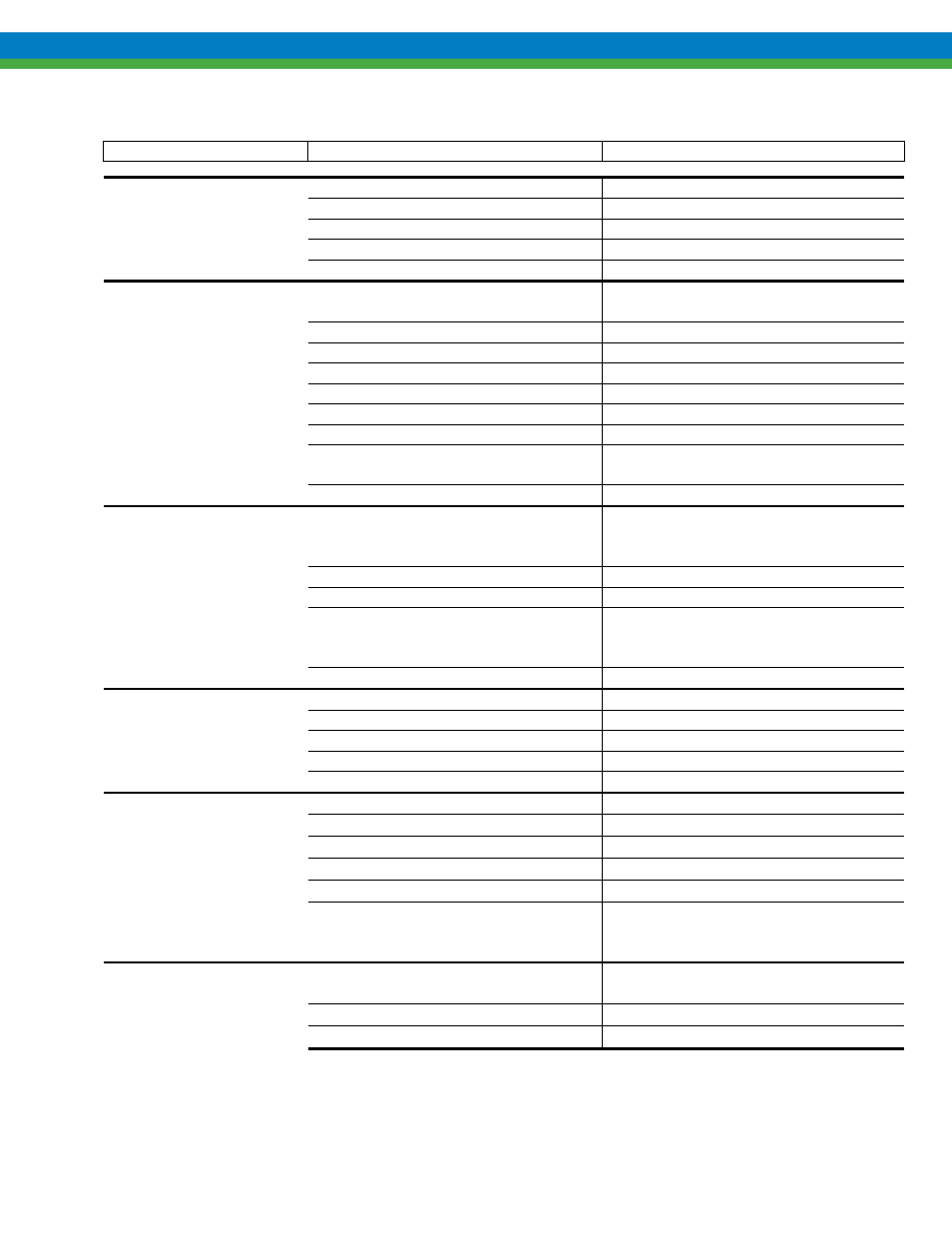

11. Troubleshooting

Difficulty

Probable Cause

Remedy

Pump does not start

Faulty power source.

Check power source.

Blown fuse, circuit breaker.

Replace - eliminate overload.

Broken wire.

Locate and repair.

Wired improperly.

Check diagram.

Process piping blockage.

Open valves, clear other obstructions.

No delivery

Motor not running.

Check power source. Check wiring

diagram (see above).

Supply tank empty.

Fill tank.

Lines clogged.

Clean and flush.

Closed line valves.

Open valves.

Ball check valves held open with solids. Clean – inspect, flush with clear fluid.

Vapor lock, cavitation.

Increase suction pressure.

Prime lost.

Re-prime, check for leak.

Strainer clogged.

Remove and clean. Replace screen if

necessary.

Stroke adjustment set at zero.

Increase stroke length setting.

Low delivery

Motor speed too low

Check voltages, frequency, wiring, and

terminal connections. Check nameplate

vs. Specifications.

Check valves worn or dirty

Clean, replace if damaged

Calibration system error

Evaluate and correct

Product viscosity too high

Lower viscosity by increasing product

temperature or dilution. Increase pump

and/or piping size

Product cavitating

Increase suction pressure.

Delivery gradually

drops.

Check valve leakage.

Clean, replace if damaged.

Leak in suction line.

Locate and correct.

Strainer fouled.

Clean or replace screen.

Product change.

Check viscosity and other variables.

Supply tank vent plugged.

Unplug vent.

Delivery erratic.

Leak in suction line.

Locate and correct.

Product cavitating.

Increase suction pressure.

Entrained air or gas in product.

Consult factory for suggested venting.

Motor speed erratic.

Check voltage and frequency.

Fouled check valves.

Clean, replace if necessary.

Inadequate backpressure

Increase discharge pressure to obtain a

minimum pressure difference of 5 pis

from suction to discharge

Delivery higher than

rated.

Suction pressure higher than discharge

pressure.

Install backpressure valve or consult

factory for piping recommendations.

Back pressure valve set too low.

Increase setting.

Back pressure valve leaks.

Repair, clean, or replace.