Mody Pumps G 902_G906TSS316 User Manual

Page 5

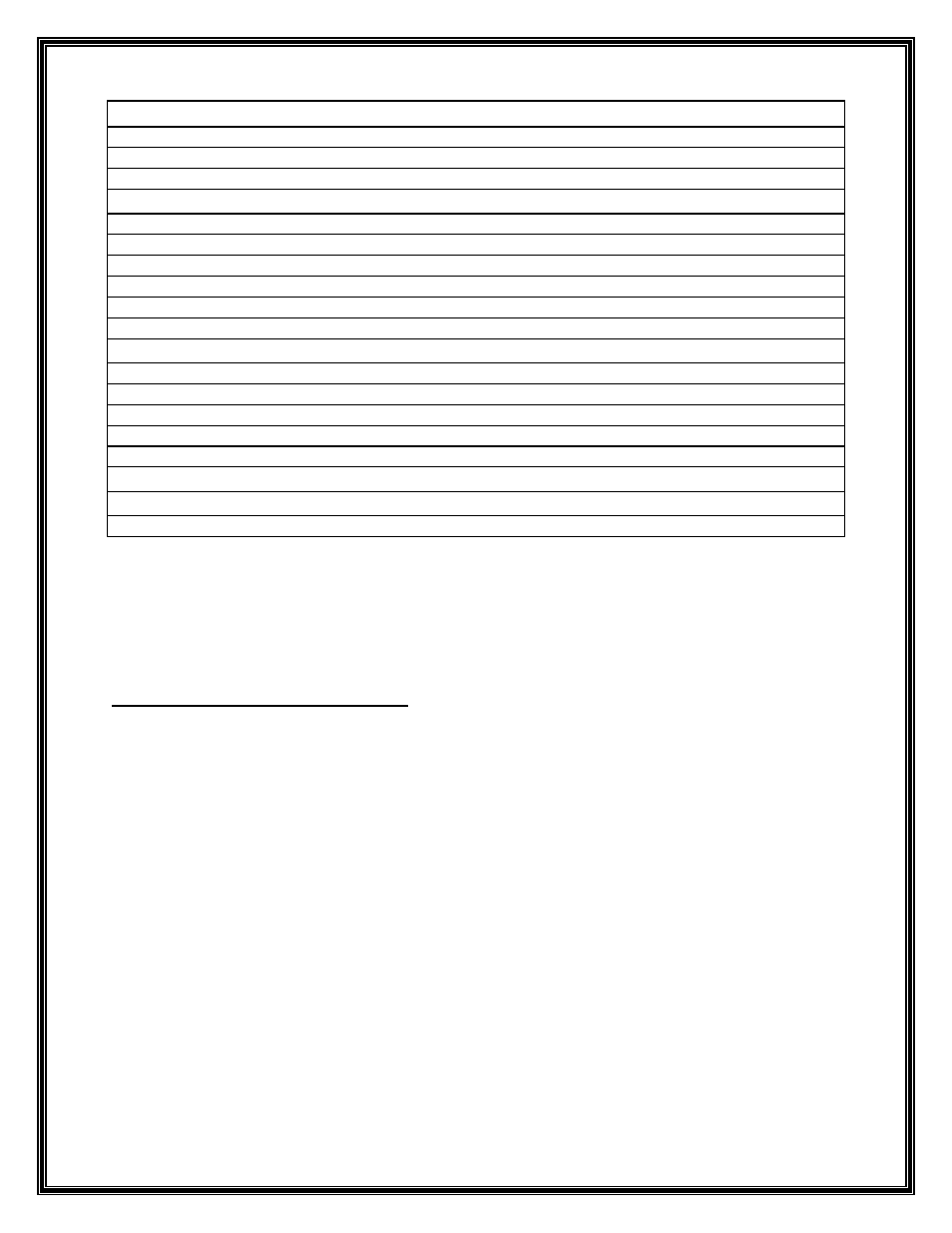

TROUBLE GUIDE CAUSE REMEDY

1.FUSES BLOWN. 1.REPLACE FUSES

2.CABLE DAMAGED 2.SHORTEN/REPLACE CABLE

PUMP DOES NOT START

. 3 NO POWER. 3.CHECK SOURCE

4.BLOCKED IMPELLER. 4.CLEAN BOTTOM PARTS.

5.STATOR WINDING BURNT. 5.REPLACE STATOR.

1.BLOCKED IMPELLER. 1.CLEAN BOTTOM PARTS.

2.IMPELLER ROT. WRONG 2.SHIFT TWO PHASE CONN.

PUMP STARTS BUT STOPS.

3.CONNECTED FOR WRONG 3.CHECK & RECONNECT.

VOLTAGE.

4.VOLTAGE TOO LOW/HIGH. 4.APPROACH POWER CO.

1.IMPELLER ROT.BACKWARD. 1.SHIFT TWO PHASE CONN.

2.PUMP WORN DOWN. 2.REPLACE IMPELLER.

PUMP GIVES TOO LITTLE

3.LONG HOSE AND DIAMETER 3.CHECK PRESSURE LOSSES

WATER.

TOO SMALL.

4.PRESSURE HEAD TOO HIGH 4.INSTALL BIGGER PUMP.

MAINTENANCE REQUIREMENTS

.

THE SERVICE LIFE OF A SUBMERSIBLE PUMP DEPENDS MAINLY ON TWO THINGS: THE

DEPENDABILITY OF THE SEALING SYSTEM AND THE WEAR RESISTANCE OF THE PUMP ITSELF.

• CHECK LEVEL AND CONDITION OF THE OIL AT SERVICE EVERY SIX MONTHS. IF THE

OIL IS EMULSIFIED BY WATER THE SEAL PACKAGE MUST BE REMOVED FROM THE ROTOR

SHAFT FOR FURTHER ACTION.

• THE SHAFT SEAL SHOULD BE CHECKED FOR WEAR EVERY 2500 HRS. OF OPERATION. IF

SEAL FACES SHOW ANY SIGNS OF WEAR, THEY SHOULD BE RECONDITIONED/REPLACED.

REFER SHEET 2 FOR SERVICE OF THE SEAL PACKAGE.

• ENSURE THAT THE PUMP IS PROPERLY TRIMMED AT ALL TIMES. AS THE IMPELLER GETS

WORN OUT, THE CAPACITY OF THE UNIT WILL DROP, AND IT IS ESSENTIAL TO

MAINTAIN THE ORIGINAL CLEARANCE BETWEEN THE IMPELLER AND DIFFUSER TO OBTAIN

SATISFACTORY PERFORMANCE. THIS CAN BE ADJUSTED BY INSERTING METALLIC SHIMS

BEHIND THE IMPELLER BOSS.

• PERIODICALLY (ONCE A MONTH) IT IS ADVISABLE TO DISMANTLE THE STRAINER AND TO

CLEAN THE IMPELLER CAVITIES. FREQUENTLY FOREIGN MATTER WILL BE DEPOSITED

WHICH SHOULD BE CLEANED FOR OPTIMUM PERFORMANCE.