Gas pressure regulator – A.O. Smith BTI 120 User Manual

Page 12

12

MALFUNCTION OF THE SUPPLY SYSTEM, THE GAS VALVE

MUST BE CHECKED FOR SAFE OPERATION. MAKE SURE

THAT THE OUTSIDE VENTS ON THE SUPPLY REGULATORS

AND THE SAFETY VENT VALVES ARE PROTECTED AGAINST

BLOCKAGE. THESE ARE PARTS OF THE GAS SUPPLY SYSTEM,

NOT THE HEATER. VENT BLOCKAGE MAY OCCUR DURING

ICE STORMS.

TABLE 6 - GAS SUPPLY LINE SIZES (IN INCHES)*

MAXIMUM CAPACITY OF PIPE IN

CUBIC FEET PER HOUR

LENGTH

NOMINAL IRON PIPE SIZES (INCHES)

IN

FEET

1/2" 3/4" 1" 1 1/4" 1 1/2"

2"

2 1/2"

3"

4"

10

175 360 680 1400 2100 3960

6300

11000 23000

20

120 250 465 950

1460 2750

4360

7700 15800

30

97

200 375 770

1180 2200

3520

6250 12800

40

82

170 320 660

990

1900

3000

5300 10900

50

73

151 285 580

900

1680

2650

4750

9700

60

66

138 260 530

810

1520

2400

4300

8800

70

61

125 240 490

750

1400

2250

3900

8100

80

57

118 220 460

690

1300

2050

3700

7500

90

53

110 205 430

650

1220

1950

3450

7200

100

50

103 195 400

620

1150

1850

3250

6700

125

44

93

175 360

550

1020

1650

2950

6000

150

40

84

160 325

500

950

1500

2650

5500

175

37

77

145 300

460

850

1370

2450

5000

200

35

72

135 280

430

800

1280

2280

4600

IT IS IMPORTANT TO GUARD AGAINST GAS VALVE FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE

INTERNALLY TINNED AND CERTIFIED FOR GAS SERVICE.

BEFORE ATTACHING THE GAS LINE, BE SURE THAT ALL GAS

PIPE IS CLEAN ON THE INSIDE.

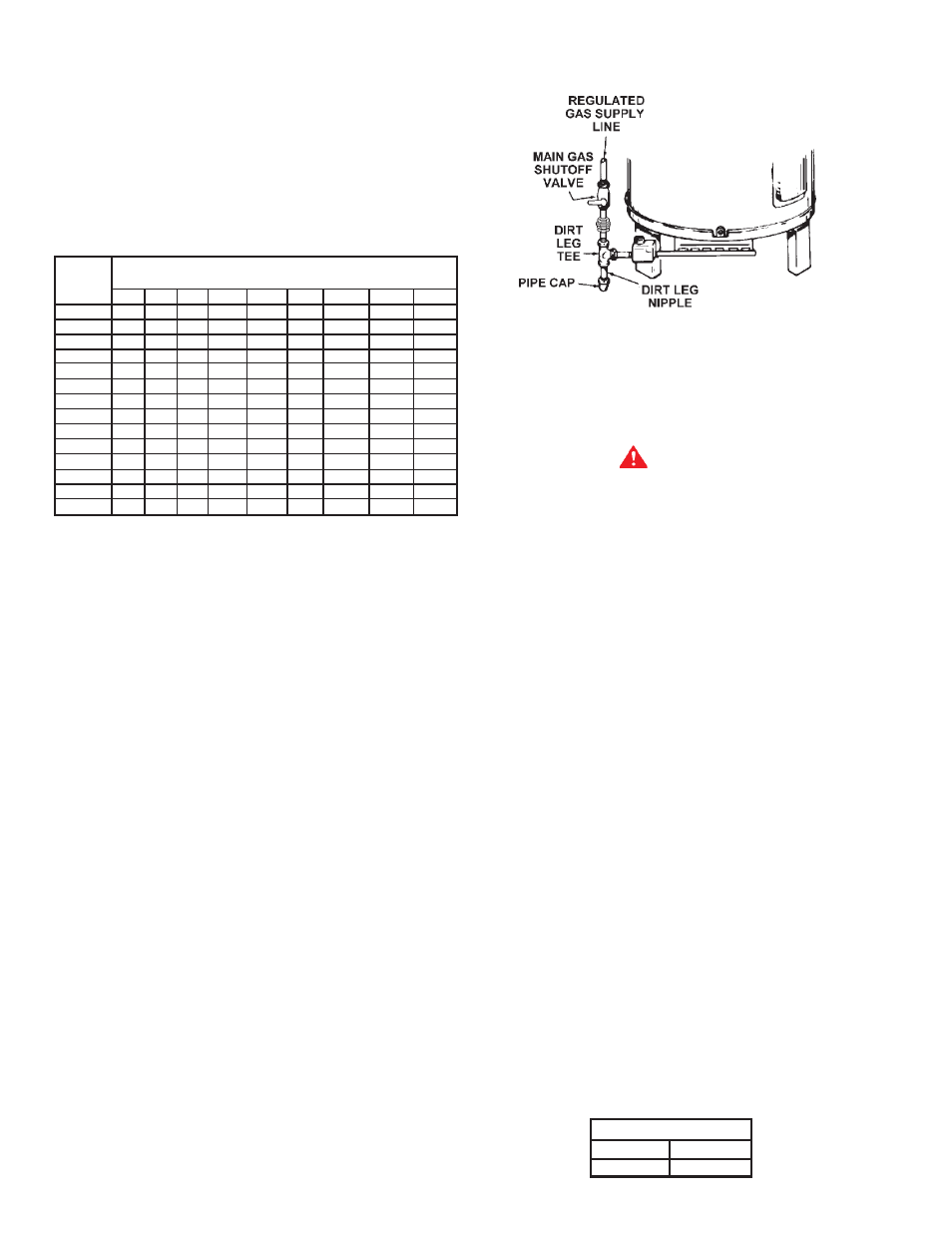

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED SEDIMENT

TRAP OR DRIP LEG) MUST BE INCORPORATED IN THE PIPING

(SEE FIG. 8). THE DIRT LEG MUST BE READILY ACCESSIBLE

AND NOT SUBJECT TO FREEZING CONDITIONS. INSTALL IN

ACCORDANCE WITH RECOMMENDATIONS OF SERVING GAS

SUPPLIERS. REFER TO THE LATEST VERSION OF THE

NATIONAL FUEL GAS CODE.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to gas valve inlet.

Apply joint compounds (pipe dope) sparingly and only to the

male threads of pipe joints. Do not apply compounds to the first

two threads. Use compounds resistant to the action of liquefied

petroleum gases.

BEFORE PLACING THE HEATER IN OPERATION, CHECK FOR

GAS LEAKAGE.

Use soap and water solution or other material

acceptable for the purpose in locating the leaks.

DO NOT USE

MATCHES, CANDLES, FLAME OR OTHER SOURCES OF

IGNITION FOR THIS PURPOSE.

DISCONNECT THE HEATER AND ITS MANUAL GAS SHUTOFF

VALVE FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY

SUPPLY PRESSURE TESTING EXCEEDING 1/2 PSIG. GAS

SUPPLY LINE MUST BE CAPPED WHEN DISCONNECTED

FROM THE HEATER FOR TEST PRESSURES OF 1/2 PSIG OR

LESS. THE APPLIANCE NEED NOT BE DISCONNECTED, BUT

MUST BE ISOLATED FROM THE SUPPLY PRESSURE TEST BY

CLOSING THE MANUAL GAS SHUTOFF VALVE.

GAS PIPING AND DIRT LEG INSTALLATION

FIGURE 9

PURGING

Gas line purging is required with new piping or systems in which

air has entered.

CAUTION

PURGING SHOULD BE PERFORMED BY PERSONS

EXPERIENCED IN THIS TYPE GAS SERVICE. TO AVOID RISK

OF FIRE OR EXPLOSION, PURGE DISCHARGE MUST NOT

ENTER CONFINED AREAS OR SPACES WHERE IGNITION CAN

OCCUR. THE AREA MUST BE WELL VENTILATED AND ALL

SOURCES OF IGNITION MUST BE INACTIVATED OR REMOVED.

GAS METER SIZE — NATURAL GASES ONLY

Be sure the gas meter has sufficient capacity to supply the full

rated gas input of the water heater as well as the requirements

of all other gas fired equipment supplied by the meter. If gas

meter is too small, ask the gas company to install a larger meter

having adequate capacity.

GAS PRESSURE REGULATOR

The gas pressure regulator is built into the gas valve and is

equipped to operate on the gas specified on model and rating

plate. The regulator is factory adjusted to deliver gas to burner at

correct water column pressure allowing for a nominal pressure

drop through the controls.

The minimum gas supply pressure for input adjustment must

not be less than 4.5" w.c. for natural gas.

Do not subject the combination gas valve to inlet gas pressures

of more than 14.0" W.C. - natural gas. A service regulator is

necessary if higher gas pressures are encountered.

Gas pressure specified in Table 7, refer to flow pressure taken

at pressure tap of automatic gas valve while heater is operating.

TABLE 7

MANIFOLD GAS PRESSURE IN INCHES

OF WATER COLUMN (ALL MODELS*)

TYPE OF GAS

Natural

Propane

3.5

10.0