Mach III Clutch T4C2H-21L, T4C2H-21LCA, T4C2H-21LSS User Manual

Page 4

7/9/2013

TORQLIM_NEMA_MANUAL

Page 4 of 5

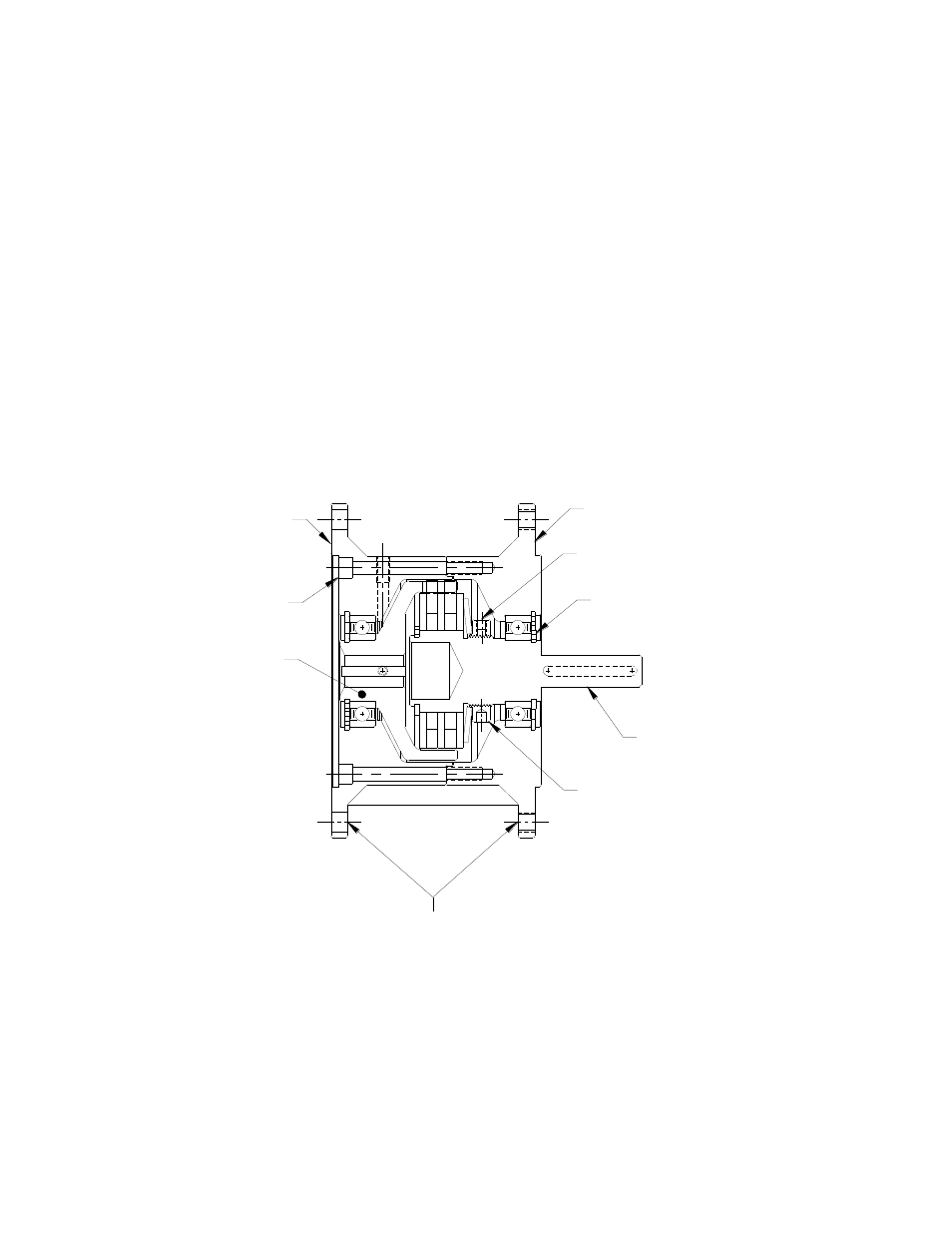

MOUNTING

HOLES

G

D

C

F

E

B

A

H

B. FRICTION DISC & SPRING REPLACEMENT

(1)

Remove the spring, drive discs and friction discs.

(2)

Drive discs should be clean, dry and free of burrs or nicks.

(3)

Reassemble drive & friction disc section according to reference drawing using new

spring, drive discs & friction discs as necessary.

(4)

Assure that drive discs move freely on the drive hub and that the lugs of the friction disc

discs move freely in the drive slots of the sleeve.

C. REASSEMBLY

(1)

Replace the spring and nut.

(2)

Adjust to desired torque by placing the tabs of the friction discs into the slots of the

female hub which should be attached to a fixed shaft. A torque wrench can be attached

to the drive hub and adjustments to the nut should be made until the desired torque is

achieved.

(3)

Tighten locking screw in adjustment nut.

(4)

Insert drive hub into bearing using Loctite

®

#609 retaining compound on inner race of

the bearing (if needed old Loctite

®

can be removed using a scraper) and replace

retainer ring.

(5)

Place housing halves back together and reinstall the 3 cap screws.

(6)

See “Torque Limiter Installation” portion of these instructions for the proper procedure

for reinstalling to the motor.

VII.

Torque Setting Instructions

(1) Remove the (3) socket head cap screws (REF. A) from the female adapter (REF. B).

(2) Separate the two halves of the torque limiter.

(3) Remove the retainer ring (REF. C) from the drive hub (REF. D).

(4) Using a non-marring mallet, remove the drive hub from the male adapter (REF. E).

Note: Using a press to remove the drive hub is also acceptable.