Mach III Clutch M6G2G-STH & M6G2G-STL User Manual

Page 3

7/9/2013

CLUTCH_MECH_W_COUPL_AIR_RD_MANUAL

Page 3 of 4

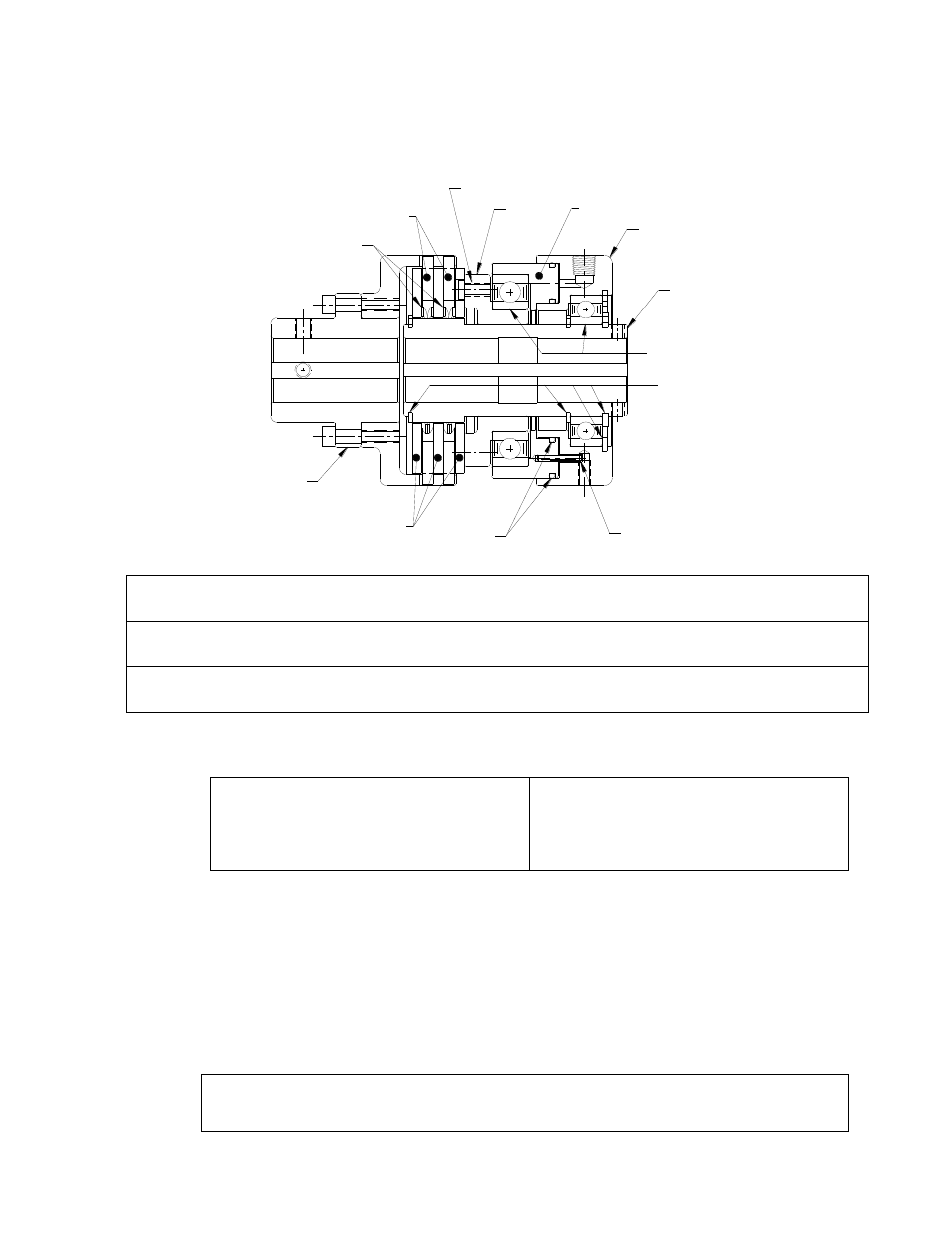

O-RING

DRIVE DISC

SPRING

PIN

SCREW

COUPLING

PISTON

FRICTION DISC

CONE

CYLINDER

DRIVE HUB

BEARING

RETAINER RING

IV.

Routine Maintenance

When installed and operated according to the preceding guidelines, Mach III Clutch

products should require little or no routine maintenance. A repair kit is available which

contains all parts subject to typical wear: friction discs, springs and O-rings.

V.

Parts diagram

Repair Kit:

Part number = Clutch Product Number + “-RPRK” (e.g. M3G2R-STH-RPRK)

Additional

Parts:

Contact Mach III to obtain a complete listing of additional parts kits available for

your specific clutch. Please reference product number when calling or e-mailing.

Repair

services:

Factory repair is available. A return materials authorization (RMA) number must

be obtained prior to sending any unit in for repair

VI.

Repair Kit Installation Procedure

Tools Required

Hex Wrench Set

Rubber Mallet or similar soft face hammer

Retainer (snap) Ring Pliers

Scraper

Compounds Required

Grease

O-ring Lubricant

Loctite

®

#609 Retaining Compound

Anti-Seize Lubricant (for re-installation)

A. FRICTION DISC & SPRING REPLACEMENT

(1)

Remove clutch from shaft and place in vertical position with drive disc end facing

upward.

(2)

Remove retainer ring, drive discs, springs and friction discs.

(3)

Drive discs should be clean, dry and free of burrs or nicks.

(4)

Reassemble drive & friction disc section according to reference drawing using new

friction discs, springs and steel drive discs as necessary.

(5)

Assure that drive discs move freely on the drive hub and that the lugs of the friction

discs move freely in the drive slots of the adapter.

Note Regarding Wave Spring Alignment:

The beginning of the coil of each spring should be placed in the same relative (O-Clock)

position to the drive hub to assure equal separation of the drive disc.