7720 series, Installation instructions – KING 7720 Series User Manual

Page 2

(714) 891-0008 • www.kinginstrumentco.com

When it comes to flow...we’re instrumental.

2

7720 Series

Installation Instructions

caution

• O-rings should be replaced if meter is disassembled

after it has been in service.

• Do not loosen nuts that fasten indicator housing

to metering tube. If the relationship of meter tube

and indicator housing are changed, meter must be

calibrated.

• Serious property damage and great personal injury

could occur as the result of a meter misused or used in

an unsuitable application.

repair

7720 meters that require repair should be sent to the

factory. Please call for aReturn Merchandise Authoriza-

tion (RMA) number and return instructions.

warning:

Pressure and temperature ratings are based on a study

of the engineering data for particular materials used in

construction and on the design of individual models.

This information is supplemented by destructive test

results. Meters with stainless enclosures must never

be operated without shields securely in place. Meters

exposed to difficult environments such as those created

by certain chemicals, excessive vibration or other stress

inducing factors could fail at or below the suggested

maximums. Never operate meters above pressure and

temperature maximums. It is strongly recommended

that all meter installations utilize an appropriate pres-

sure relief valve and/or rupture disc. The pressure set-

tings and locations of these devices should be such that

meters cannot be over pressurized. Meter failure could

result in damage to equipment and serious personal

injury. Always use suitable safety gear, including OSHA

approved eye protection when working around meters

in service. We are happy to pass along chemical com-

patibility information that has been published by the

manufacturer’s of raw materials used in our products;

however, this information should not be construed as a

recommendation made by King Instrument Company,

Inc. for a specific application.

max non-Shock Pressure and temperature

fitting

temp

Size

4 and 6

Size

8 thru 12

fNPT

130°F Max

150 psig

125 psig

150# Flange 130°F Max

150 psig

150 psig

300# Flange 130°F Max

150 psig

150 psig

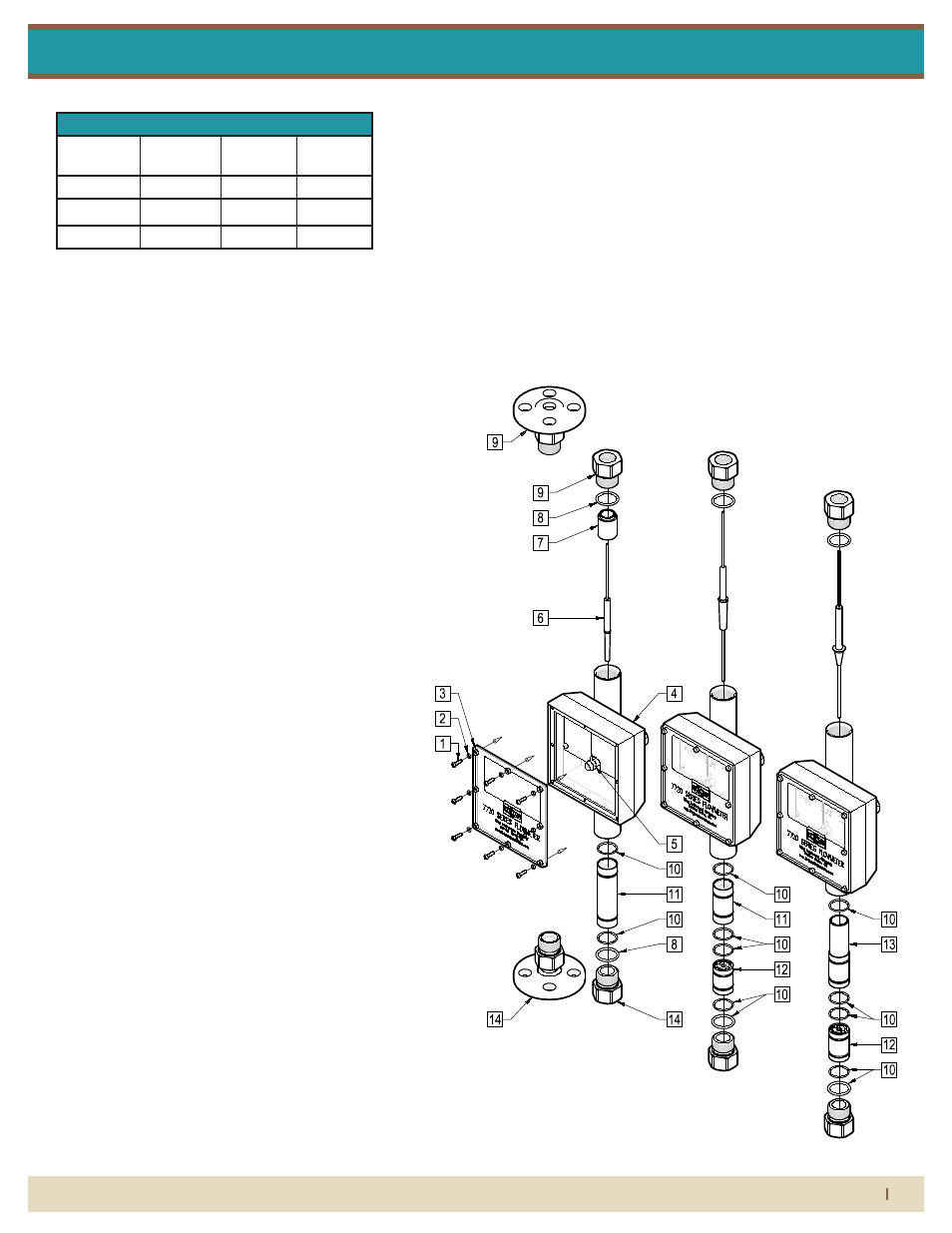

7720 series asseMbly

parts list:

1. Shield Screw

2. Shield Screw O-Ring

3. Shield With Gasket

4. Indicator Housing/Meter

Tube Assembly

5. Pointer Needle Set Screw

6. Float

7. Outlet Float Stop Housing

Assembly

8. End Fitting O-Ring

9. Outlet End Fitting

10. Orifice Housing O-Ring*

11. Orifice Housing/ Orifice

Assembly*

12. Inlet Float Stop Housing

Assembly*

13. Taper Sleeve*

14. Inlet End Fitting

*CONFIGURATIONS VARY BY FLOW

RATE AND METER SIZE.

Pressure and temperature ratings are based on a study of the engineering data

for particular materials used in construction and on the design of individual

models. This information is supplemented by destructive test results. Meters with

stainless enclosures must never be operated without shields securely in place.

Meters exposed to difficult environments such as those created by certain

chemicals, excessive vibration or other stress inducing factors could fail at or

below the suggested maximums. Never operate meters above pressure and

temperature maximums. It is strongly recommended that all meter installations

utilize an appropriate pressure relief valve and/or rupture disc. The pressure

settings and locations of these devices should be such that meters cannot be

over pressurized. Meter failure could result in damage to equipment and serious

personal injury. Always use suitable safety gear, including OSHA approved eye

protection when working around meters in service. We are happy to pass along

chemical compatibility information that has been published by the manufacturer's

of raw materials used in our products; however, this information should not be

construed as a recommendation made by King Instrument Company, Inc. for a

specific application.

Carefully remove the flowmeter from piping system. Remove the threaded outlet

end fitting and withdraw the float from the top. All necessary instrument

components are now fully accessible for cleaning with a bottle brush and

appropriate mild soap solution*. Before the meter is reassembled, inspect all

parts for damage. O-rings should be replaced during meter maintenance and

cleaning.

To reassemble, carefully guide the magnetic float back into the tube. Reinstall

and tighten outlet end fitting. Reinstall the instrument into the plumbing system

after removing the old teflon tape (with a wire brush) and replacing with fresh

teflon tape.

*Do not use cleaning agents that will damage float, tube or o-rings.

Meters should be cleaned with a mild soap solution. This will be an effective

cleaner of rust stains. Caution must be used so that materials of construction are

not damaged by cleaning solutions. Hard water deposits can be removed with 5%

acetic acid solution (vinegar).

7720 meters that require repair should be sent to the factory. Please call for a

Return Merchandise Authorization (RMA) number and return instructions.

-O-rings should be replaced if meter is disassembled after it has been in service.

-Serious property damage and great personal injury could occur as the result of a

meter misused or used in an unsuitable application.

1) Inspect meter for damage that may have occurred during shipping.

Report any damage to the container to the freight carrier immediately.

This is important information. Read it carefully

before beginning work.

2) Make sure your pressure, temperature, fluid and other

requirements are compatible with the meter and components

(including o-rings).

3) Select a suitable location for installation to prevent excess stress

on the meter which may result from:

a) Misaligned pipe.

b) The weight of related plumbing.

c) "Water Hammer" which is most likely to occur when flow is

suddenly stopped as with quick closing solenoid operated valves.

(If necessary, a surge chamber should be installed. This will also be

useful in pressure start-up situations.)

d) Thermal expansion of liquid in a stagnated or valve isolated

system.

e) Instantaneous pressurization which will stress the meter and

could result in tube failure.

NOTE: In closed thermal transfer or cooling systems, install the meter

in the cool side of the line to minimize meter expansion and

contraction and possible fluid leaks at the threaded connections.

4) Handle the meter carefully during installation.

a) Use an appropriate amount of teflon tape on external pipe

threads before making connections. Do not use paste or stick type

thread sealing products.

5) Install the meter vertically with the inlet port at the bottom.

Maximum Non-Shock

Pressure and

Temperature

O-Ring Temperature

Meters are not specifically recommended for service other than

water or air. The user must determine meter suitability for use

with other fluids.

ADDITIONALLY:

-7720 Series meters are designed for vertical installation only. (Inlet at

bottom, Outlet at top)

-Do not remove or adjust the screws on the side of the indicator

housing. These screws were positioned during factory calibration and

represent the zero adjustment. If the pointer is set on zero, proceed

with installation. If the pointer is not set at zero, follow these steps:

Caution: Zero is factory set when meter is

calibrated. DO NOT loosen screws that fasten

indicator housing to meter body. If indicator

housing is moved, the meter will need to be

calibrated.

1) Remove front cover with gasket from indicator housing.

2) Loosen set screw at the base of the pointer hub.

3) Reposition pointer to zero line.

4) Tighten set screw with a

1

16

" allen wrench by holding the pointer

hub and gently tightening the set screws.

5) Replace front cover with gasket on indicator housing.

-Do not loosen nuts that fasten indicator housing to metering tube. If the

relationship of meter tube and indicator housing are changed, meter must be

calibrated.

6) Meters with plastic fittings must be installed so that fittings are not

made to support any part of the associated plumbing. In addition,

meter frame should be fastened to bulkhead, panel or column.

SHIELD SCREW

SHIELD SCREW O-RING

SHIELD WITH GASKET

INDICATOR HOUSING/

POINTER NEEDLE SET SCREW

FLOAT

END FITTING O-RING

OUTLET END FITTING

ORIFICE HOUSING O-RING

ORIFICE HOUSING/

OUTLET FLOAT STOP

8X

8X

FLANGE

FNPT

METER TUBE ASSEMBLY

ORIFICE ASSEMBLY

HOUSING ASSEMBLY

TAPER SLEEVE

INLET END FITTING

INLET FLOAT STOP

HOUSING ASSEMBLY

FLANGE

1

1

1

1

CONFIGURATIONS VARY BY FLOW RATE AND METER SIZE.

1

EPR

225 °F

Buna-N

Viton

Kalrez

275 °F

350 °F

400 °F

O-Ring

Material

Maximum

Temperature

The maximum ambient

temperature for the indicator

housing is 158°F.

Viton and Kalrez are registered trademarks of DuPont Dow

Elastomers.

1

FNPT

Size

8 thru 12

Size

4 and 6

Temp.

125

psig

150

psig

130°F

Max.

150

psig

150

psig

130°F

Max.

FNPT

150#

Flange

150

psig

150

psig

130°F

Max.

300#

Flange