Cashco 3100 User Manual

Page 5

5

IOM-3100

SECTION VI

VI. TEST PROCEDURE

To Calculate Weight of Pallet Assembly:

Table 2 shows the pallet weight per unit of pressure

or vacuum setting. The total pallet assembly weight

is determined by multiplying the desired set point (in

the appropriate units) by the incremental weight per

unit listed in Table 2.

For Example:

4” Model 3104 CS - if the desired setting is 5 oz/in

2

Table 2 shows that for a 4” vent, the pallet would

weigh 2.05 lb per oz/in

2

So the pallet assembly for a 5 oz/in

2

setting would

weigh: 2.05 lbs/oz/in

2

x 5.0 oz./in

2

- 10.25 lbs

Valve Concepts allows a deviation from this

theoretical weight of ± 3.0%.

To Determine Diaphragm/Seat Leakage:

After both pallets’ weight has been determined and

verifi ed for the required setting, reassemble the vent

and mount on a Tank Vent Test Stand and slowly

raise the pressure at the fl ow rate of 1.0 SCFH.

ACCEPTANCE CRITERIA: The pressure gauge

shall maintain a pressure equal to or greater than

90% of set pressure for a one minute period while

the specifi ed fl ow rate is maintained. Note: Valve

Concepts acceptance criteria exceed the require-

ments of API. API 2521 states that if the rate of leak-

age does not exceed ½ SCFH for 6 inch size and

smaller, or 5 SCFH for 8 inch and larger, at 75% of

set point, then a vent is considered satisfactory for

all practical purposes.

If the vent fails to meet the 90% criteria, it must

be disassembled and the seat, pallet, and or dia-

phragms repaired or replaced.

A test report should be completed for each vent. The

report should indicate the total pallet weight and the

pressure achieved at the Test Flow Rate for both

pressure and vacuum. Other general information

such as serial number, model number, material of

construction, set pressure and vacuum, etc. should

be included in the report.

The test report should be kept with the Valve Main-

tenance Records.

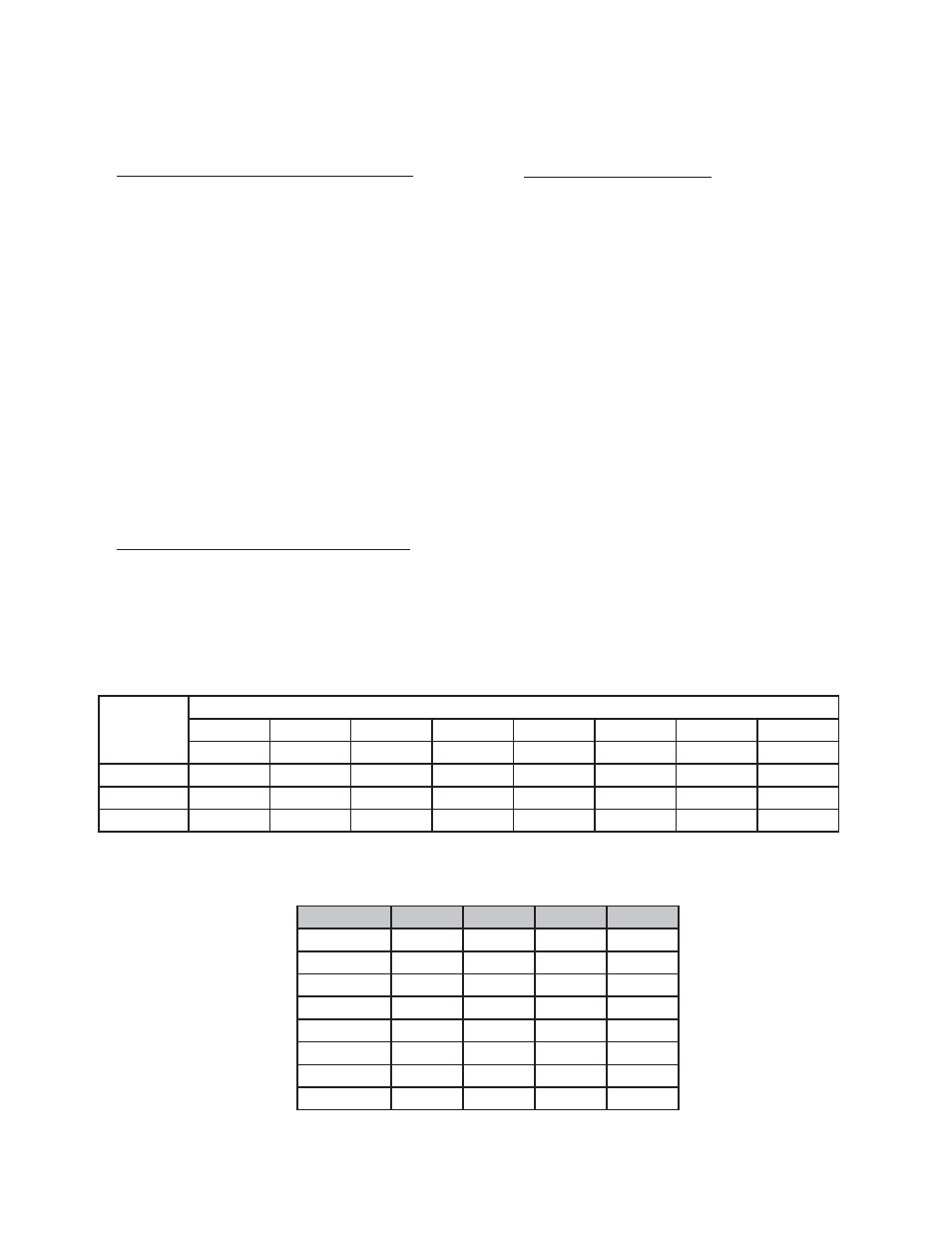

TABLE 2

Nominal Pallet Assembly Weight Per Unit of Pressure lbs (kg)

SET Point

Units

VALVE SIZE

2” VTA

2” PV

3”

4”

6”

8”

10”

12”

Lb (kg)

Lb (kg)

Lb (kg)

Lb (kg)

Lb (kg)

Lb (kg)

Lb (kg)

Lb (kg)

1.0 oz/in

2

0.25 (0.11) 0.55 (0.25) 0.93 (0.42) 2.05 (0.93) 3.50 (1.59) 5.45 (2.47) 7.71 (3.50) 9.17 (4.16)

1.0 in WC

0.15 (0.07) 0.32 (0.14) 0.54 (0.24) 1.18 (0.53) 2.03 (0.92) 3.15 (1.43) 4.46 (2.02) 5.30 (2.40)

1.0 mbar

0.13 (0.06) 0.13 (0.06) 0.22 (0.10) 0.48 (0.22) 0.81 (0.37) 1.26 (0.57) 1.79 (0.81) 2.13 (0.97)

Line Size

10 mil

20 mil

30 mil

40 mil

2” VTA

7.00

34.00

40.00

n/a

2” P/V

4.50

23.50

33.00

40.00

3” P/V

3.50

18.00

25.00

40.00

4” P/V

2.25

12.00

17.00

40.00

6” P/V

1.75

9.25

13.25

40.00

8” P/V

1.75

7.50

10.50

40.00

10” P/V

1.25

6.25

8.75

40.00

12” P/V

1.00

5.75

8.00

40.00

TABLE 3

Maximum Pressure Setting in oz/in

2

Vs. Diaphragm mil