Cashco 5400 User Manual

Page 9

9

IOM-5400

SECTION IX

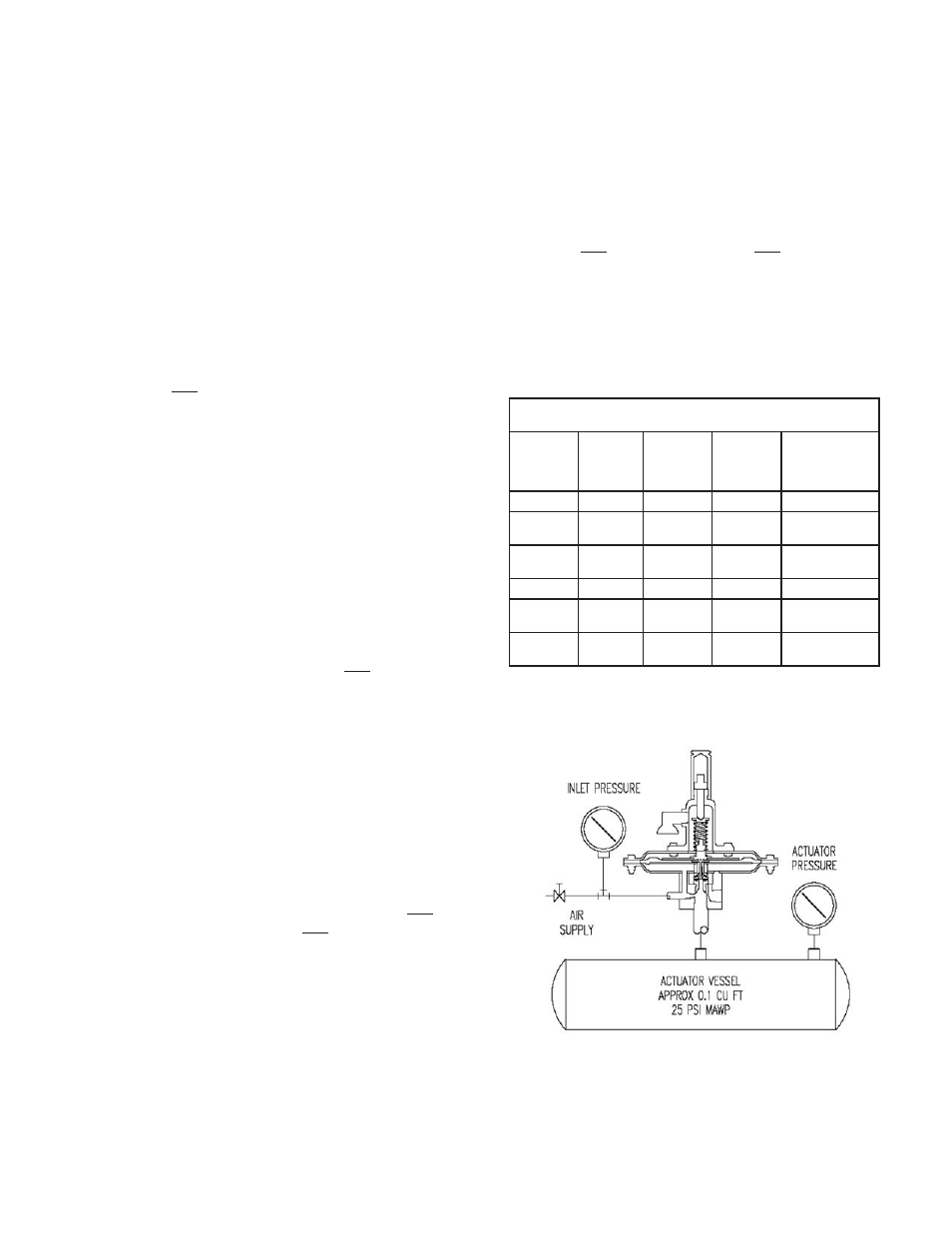

Pilot Valve Test Stand

IX. PRESSURE CALIBRATION AND

TESTING PROCEDURE FOR PILOT

1. To determine set pressure, slowly increase

the pilot inlet pressure. Simulated actuator

pressure will rise with inlet. As set pressure

is approached, the actuator pressure will be-

gin to decrease. Continue to increase the

inlet pressure slowly until the actuator pres-

sure is 90% (+/- 10%) of the inlet pressure.

This is the set pressure.

2. Rotate the set pressure adjusting screw

(213) CW to increase set pressure or CCW

to decrease set pressure. Continue to rotate

the adjusting screw and repeat the test per

Step 1 previous until the specifi ed set pres-

sure is achieved.

3. To determine reseat pressure, slowly de-

crease the inlet pressure and the actuator

pressure will begin to increase. Reseat oc-

curs when the actuator pressure equal the

inlet pressure.

4. The difference between set and reseat

pressure,”blowdown”, can be adjusted with

the blowdown needle (217). Maximum

clockwise rotation provides rapid relief valve

opening, “snap action”’ and maximum blow-

down. Standard blowdown, unless other-

wise specifi ed is 7 - 10% below set pressure.

5. Increased counter clockwise rotation of

blowdown screw provides “modulating” ac-

tion and minimum (zero) blowdown. Reseat

pressure is the same as set pressure.

NOTE: The blowdown needle is located

in a pressure containing chamber, and is

retained by the blowdown o-ring (218) and

blowdown locknut (236). DO NOT remove

the blowdown needle while under pressure.

6. Remove body vent and install a fl exible tube

in this port. Immerse this pilot discharge

bubble tube in water approximately 1/4” be-

low surface to detect cracking and reseat

pressure.

7. A small interaction occurs between set

pressure and blowdown adjustments. Re-

adjustment of both may be required until

the specifi ed set pressure and blowdown

are achieved. After completion, lock both

screws and locknuts and replace closing cap

(205) on adjusting screw (213).

8. Hold the valve at the set pressure while

preforming a soap bubble test of all bolted,

fl anged and threaded connections.

9. Refer to Table 3 for standard setting Specifi -

cations.

TABLE 3

SETTING SPECIFICATIONS - PILOT VALVE

Pilot Action

Set

Pressure

Set

Pressure

Limits

Maximum

Cracking

Pressure %

of Set

Reseat

Pressure

% of Set

Snap

2” - 8” WC

+/- 0.2”WC

75

90 +/- 3

Snap

8.1” WC -

1.0 psig

+/- 3%

90

90 +/- 3

Snap

1.1 - 15.0

psig

+/- 3%

95

93 +/- 3

Modulating

2” - 8” WC

+/- 0.2” WC

75

100

Modulating

8.1” - 1.0

psig

+/- 3%

90

100

Modulating

1.1 - 15.0

psig

+/- 3%

95

100