Disinfection procedure – Hydrotech UVSS Series Ultraviolet Water Purification System User Manual

Page 5

4

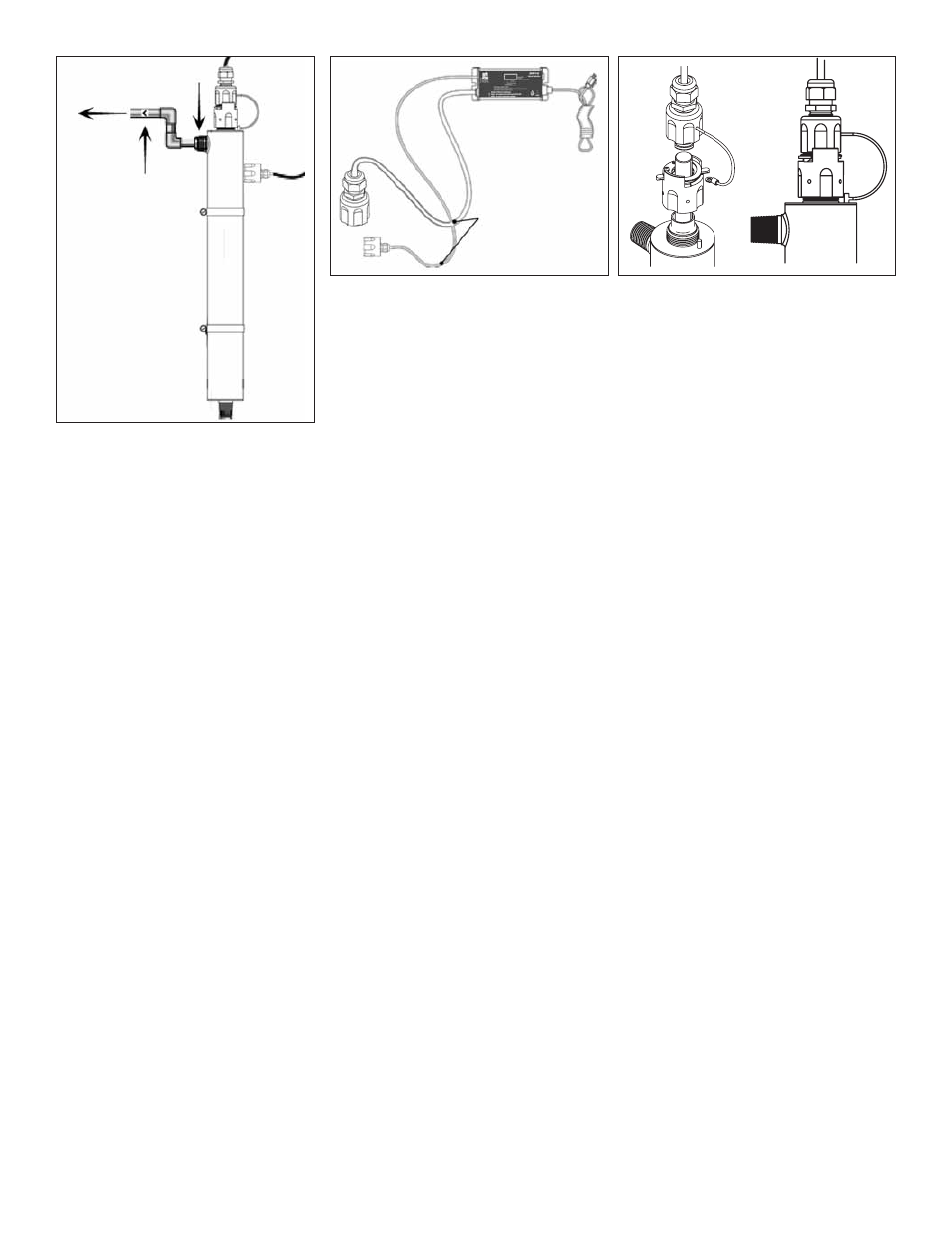

Figure 1C

Figure 1E

Flow

Flow

Restrictor

Flow direction must

be the same as

arrow on flow

restrictor.

Outlet Port

on Cell

Disinfection Procedure

UV disinfection is a physical disinfection process and does not add any potentially harmful chemicals to the water. As UV

does not provide a disinfection residual, it is imperative that the entire distribution system located after the UV be chemi-

cally disinfected to ensure that the water is free from any bacteriological contaminants. The disinfection process must be

performed immediately after the UV unit is installed and repeated thereafter whenever the UV is shut down for service,

without power, or inoperative for any reason. The procedure for sanitizing the plumbing system is readily accomplished as

follows:

1.

Shut off the upstream water supply that feeds water into the reactor chamber and depressurize water system. Remove

the pre-filter cartridge and fill the sump with 1-2 cups of household (5.25%) bleach (chlorine) - Do NOT use hydrogen

peroxide. At all times during the process, make sure the UV unit (and lamp) is turned on and operational!

2.

Repressurize water system, open each faucet and allow cold water to run until you smell chlorine, shut the faucet off

and then repeat the process for each faucet, including hot water. You must ensure that all taps, including outside faucets,

dishwashers, shower heads, washing machines, connections to refrigerators, toilets, etc., pass chlorinated water.

3.

Once all the locations have passed the chlorine disinfection solution, you will need to leave the solution sit for a peri-

od of 20 - 30 minutes. Reinstall the pre-filter cartridge into the filter and then flush the chlorine solution from the sys-

tem until no chlorine smell is detectable. Make sure that each fixture that was disinfected in step 2 is completely flushed

of the chlorine solution as the consumption of this water is not advised due to the extremely high concentration of chlo-

rine. It is important to remember that in the event that a UV is briefly shut down for routine cleaning or during power

interruptions where water could have passed through the system, the aforementioned procedure must also be fol-

lowed.

Note A: The addition of chlorine (bleach) to a hot water tank that has in the past been fed with untreated raw water with

high levels of other contaminants (iron, manganese, hydrogen sulphide, organics, etc.) will result in oxidation of these

contaminants and may require repeated flushing of the hot water tank. This contingency must be dealt with independ-

ently under the startup procedure for any other conditioners that may form a part of the pre-treatment for the UV unit.

Note B: The above procedure (Steps 1 to 3) will result in a massive chlorine residual far in excess of the 0.5 to 1.0

mg/L typically present in municipally chlorinated water and of a magnitude consistent with the minimum 50 mg/L chlo-

rine solution recommended for the disinfection of distribution systems known to be contaminated. Do not consume

water until complete system has been flushed.

PLEASE NOTE: For UVSS-M models which include a 254nm UV intensity monitor, it should be noted that the introduc-

tion of the bleach solution required for disinfection

WILL trigger a temporary low UV condition. This is due to the fact that

the bleach physically ‘clouds’ the raw water. Once the bleach runs through the system, the alarm condition will return to

normal. During this sanitization process, the audible alarm condition on the controller can be temporarily deferred by press-

ing the “RESET” switch for 5 seconds. By doing this, the audible alarm will be silenced and the solenoid relay will close

(AC power will be provided to the normally closed (NC) solenoid, allowing water to pass through the system). The system

will display [ A2 ] on the controller LED. This condition will remain for 12 hours unless the system is manually reset as out-

lined on page 7 of this manual.

Figure 1D

Drip Loop