Hydrotech Aqua Flo Ultra 2 Under Sink Filter System User Manual

Page 4

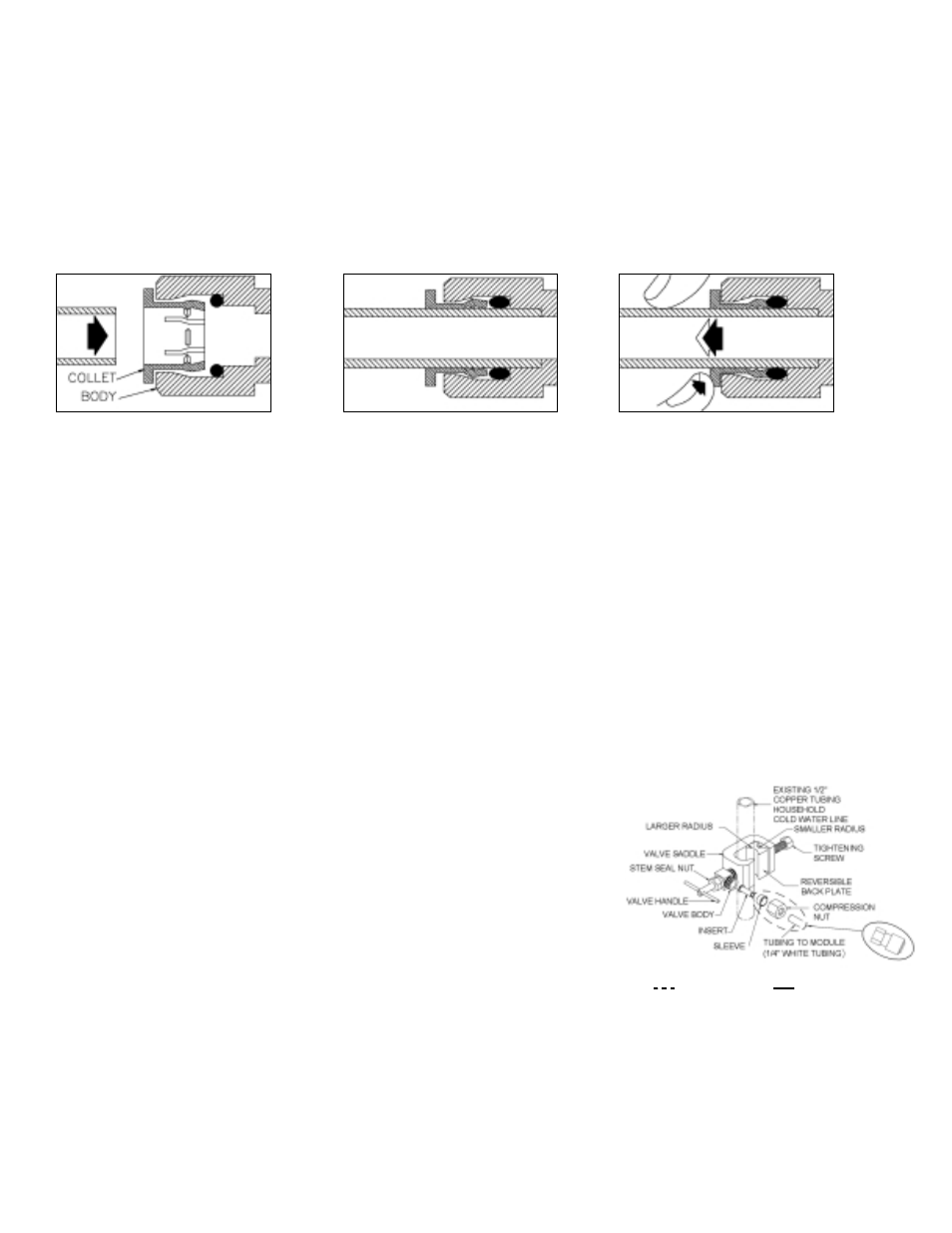

Instruction #2 - Install Tubing to Quick Connect Fittings

PLASTIC TUBING

1. Cut tube ends square and straight.

Do not deform tube (i.e., cause tube

to compress its diameter so it is no

longer round).

2. Make sure outer surface of tube is

clear of marks or scratches for a

length equal to twice tube diameter.

This allows "O" ring to seat properly

against tube.

3. Avoid sharp changes in direction

when routing tubing. Sharp turns

cause tubing to flex and deform,

which reduces its flow capacity and

may increase lateral stress on the

fittings, causing leakage.

QUICK-CONNECT FITTINGS

Fittings consist of two parts: a Body and

a collet.

1. To install a tube, push it through

Collet until it seats firmly at bottom of

fitting (Figure A and B.).

2. To remove a tube, push and hold

Collet against Body while pulling tube

out (Figure C).

A. Push tube through Collet into Body.

B. Tube must seat firmly at bottom

of fitting.

C. Push Collet against Body to

release tube.

Instruction #3 - Saddle Tapping Valve Installation on Copper Tube

CAUTION: This saddle-tapping valve is

not designed for installation on flex line

tubing.

NOTE: State, provincial and local

plumbing codes may prohibit use of

saddle-tapping valves.

1. CAUTION: If no shut off valve is

installed under sink, close main water

valve during this Installation.

Locate shut off valves on water lines

under sink. To identify hot supply pipe

and cold supply pipe, turn both

faucets on and let water run. As water

flows, hot water pipe becomes

noticeably warmer.

2. CAUTION: Do not install feed water

assembly on hot water line.

Turn off cold water supply by closing

shut off valve. Drain line by opening

sink faucet. Some mixing type faucets

may require hot water supply be shut

off as well.

NOTE: All instructions refer to

components shown in Figure 1 unless

otherwise noted.

3. CAUTION: Do not turn valve handle

before or while installing saddle-

tapping valve. Make sure piercing

lance does not protrude beyond

rubber gasket before installing valve.

Assemble saddle-tapping valve

assembly on tube.

a.

Hold back plate against tube.

• 3/8" copper tubing use back

plate smaller radius.

• 1/2" copper tubing, use back

plate larger radius

b.

Hold valve saddle against tubing

in a position directly opposite

back plate.

c.

Tighten screw enough so valve

saddle and back plate are held

securely against tube.

d.

Rotate assembly so tubing

connection is aligned toward RO

Module feed port.

e.

Tighten screw firmly. Do not

crush tube.

4A. Connect source water feed tubing to

valve body using compression fitting.

a.

Slide nut and sleeve onto tubing

(in that order).

b.

Install insert into plastic tubing.

c.

Install tube with insert and

sleeve into valve body.

d.

Thread compression nut onto

valve body, tighten.

4B. Connect source water feed tubing to

valve body using connector.

a.

Apply NSF 61 grade Teflon tape

over the threads of valve body.

b.

Install the connector (Do not

overtighten)

c.

Firmly push the white tubing into

the quick connect fitting of

connector.

5. Turn saddle-tapping valve handle

clockwise until it is firmly seated and

piercing lance is fully extended.

6. CAUTION: Supply line is pierced and

valve is closed.

Do not open valve until system is

activated.

Turn on cold water supply. Check

saddle-tapping valve installation for

leaks. Allow water to run from faucet

for a few minutes to clear any debris

in the line caused by installation.

NOTE: If flow from sink faucet is

reduced, clean faucet aerator.

Figure 1: Saddle-Tapping Valve Assembly

P/N 92276 installed on 1/2”

Copper Tubing

7. Trim ¼” white tube to desired length.

Install ¼” white tube into ¼” white

collet as shown in Figure 1.

Compression

Nut Fitting

Connector