Installation and start-up procedure, Installation instructions – Hydrotech 2510 Valve nextSand Turbidity & Sediment Filter Operation Manual User Manual

Page 3

2

Installation Instructions

CAUTION:

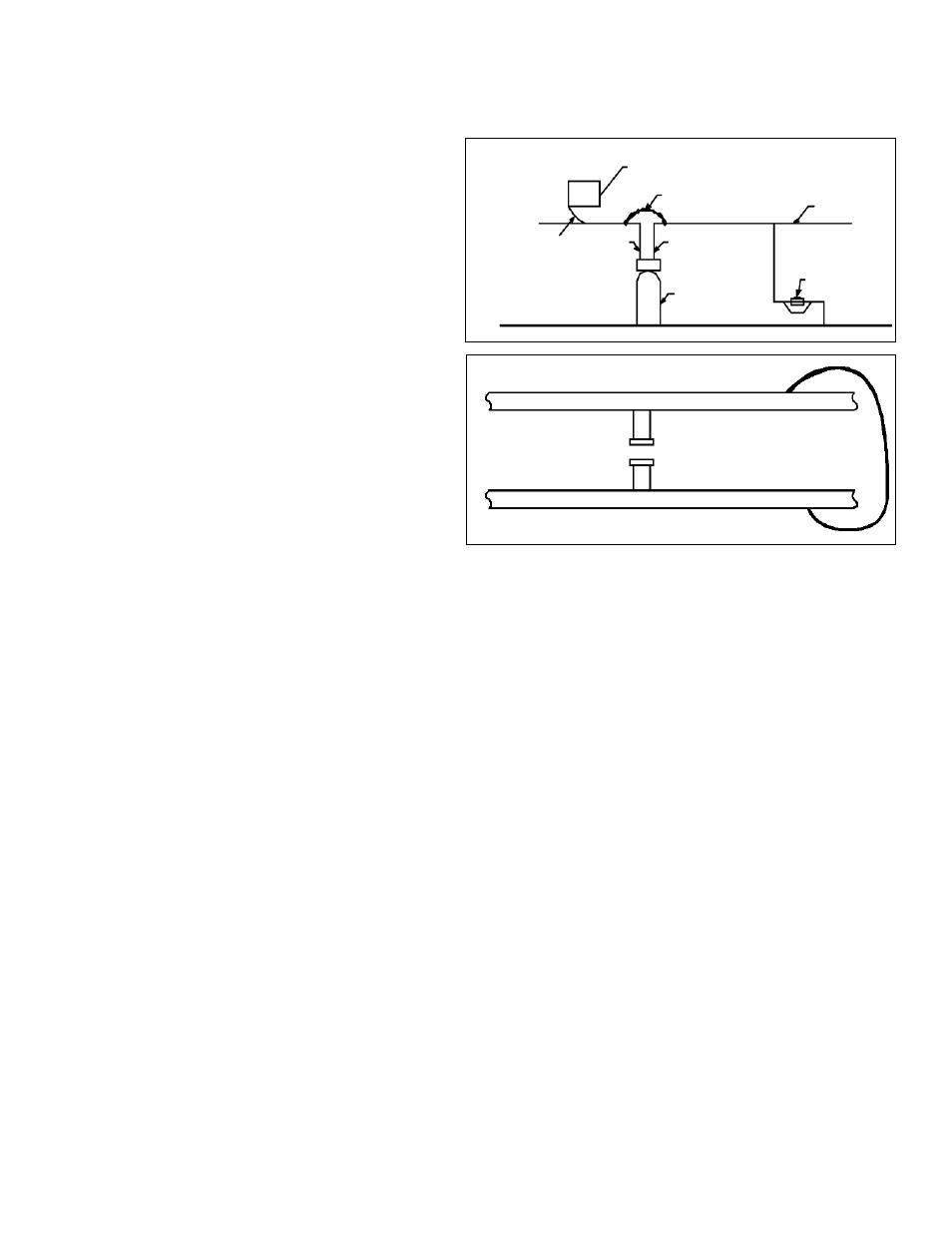

If the ground from the electrical panel or breaker box to the water

meter or underground copper pipe is tied to the copper water

lines and these lines are cut during installation of a Noryl bypass

valve and/or poly pipe, an approved grounding strap must

be used between the two lines that have been cut in order to

maintain continuity. The length of the grounding strap will depend

upon the number of units being installed and/or the amount of

copper pipe being replaced with poly. See Figure 1.

In all cases where metal pipe was originally used and is later

interrupted by poly pipe or the Noryl bypass valve as in Figure

1 or by physical separation as in Figure 2, to maintain proper

metallic pipe bonding, an approved ground clamp c/w not less

than #6 copper conductor must be used for continuity.

Check your local electrical code for the correct clamp and cable

size.

NOTE: This timer’s programs will be out of sync if you turn the

knob too far or do not allow the drive motor to stop completely

before continuing to the next step. If this happens while doing any

procedure, rotate the knob clockwise until the white dot lines up

with the time of day arrow and the unit will return to the service

position. You can then start again.

1. Place filter with chemical feeder container on a flat surface in desired location, near a drain and 115 volt AC outlet. Subjecting your

filter to freezing or to water temperatures above 120°F (49°C) will void the warranty. Remove the valve from the carton. Be sure the

distributor tube is in place. Carefully position the valve over it and turn securely on to the fiberglass tank.

Note: All multi media and some larger units are supplied with the media separate. Please refer to page 5 installations & Replacement

of Filter Media Pak.

2. Attach the installation kit or bypass to the control valve. Make inlet and outlet water connections to meet applicable plumbing codes.

A 3/4” inlet line is recommended. When sweat fittings are used, solder the adapters for the inlet and outlet to the copper pipe first.

This procedure is necessary because the controls must not be subjected to temperatures above 160°F (71°C). Then, using teflon

tape, screw the adapters for the inlet, outlet and drain into the valve. CAUTION: Do not use pipe thread compound as it may attack

the materials in the valve body.

3. On the drain, use the 1/2" hose barb supplied and a full 1/2" hose (not supplied) for the drain line and make the shortest run to a

suitable drain. The drain line must be secured in position at the end which discharges into the drain so it cannot be inadvertently

moved from the drain. An air gap may be required.

4. Loosen the two screws on the timer cover to remove it from the timer.

5. Automatic water filters are supplied from the factory in the backwash position, ready for start up. Turn on the water supply to the

unit. Open the supply line slowly and allow the air to escape from the filter before turning the supply water on all the way. Allow the

unit to backwash until all the air and media fines are no longer showing at the drain. This may take up to 15 minutes so you need

to unplug the timer until you are ready to continue.

6. Plug the timer in, set the time and frequency of regeneration following instruction on page 4. Allow the unit to complete the cycle on

its own from this point.

7. Make sure the bypass valve is in the service position.

ALL GOVERNMENT CODES GOVERNING INSTALLATIONS OF THESE DEVICES MUST BE OBSERVED.

Installation and Start-up Procedure

Electrical Panel

Ground Strap

Copper

Pipe

Filter

c/w Plastic

Bypass

Ground

From

Panel

Poly Pipe

Poly

Pipe

Water

Meter

Unfiltered Water Line for Outside & 3rd Tap Comes from Meter

Unfiltered Water Bypass

Loop Cut & Capped

Ground Strap Required

Because of break in continuity

Filtered Water Line in Home

Figure 1

Figure 2