Aqua-lab evo, In-bay chemical dispensing system – Hydra-Flex Aqua-Lab EVO User Manual

Page 2

680 East Travelers Trail • Burnsville, MN 55337

T: 952-808-3640 • F: 952-808-3650 • www.hydraflexinc.com • [email protected]

P/N EVO RevA0214

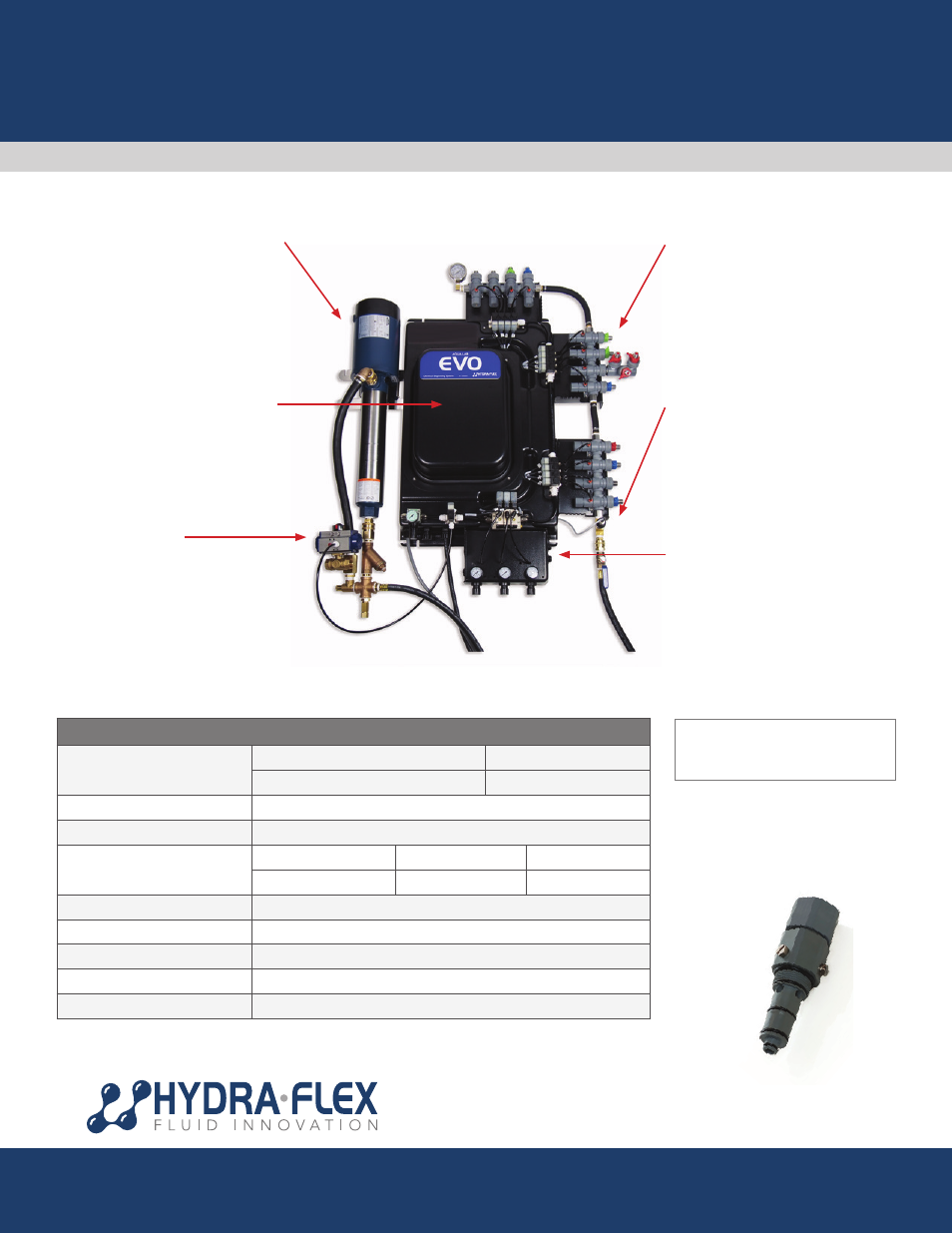

AQUA-LAB EVO

IN-BAY CHEMICAL DISPENSING SYSTEM

TM

SYSTEM REQUIREMENTS/SPECIFICATIONS

Power Requirements

10 GPM Pump

Air-Actuated Valves

208-230V/3PH/8A or 460V/3PH/4A

24VDC, 3.5 Watts per port

Space Requirements

38” W x 44” H with pump assembly

Water Inlet Line

3/4” ID

Solution Outlet Lines

Up to 3.25 GPM

3.25 GPM-5.5 GPM

5.5-8 GPM

3/8” ID (1/2” Polyflow)

1/2” ID

5/8” ID

Operating Water Pressure

200 PSI Factory Set

Max. Water Source Temperature

140ºF (+60ºC)

Air Inlet Line

3/8” OD Polyflow

Air Outlet Line

3/8” OD Polyflow Per Application

Air Inlet Pressure

20 CFM @ 80-100 PSI Dry Air

INTEGRATED 10 GPM PUMP

Includes quick-connects, Wye

strainer, bypass pressure regulator

and thermal relief valve for safe and

reliable operation.

PRESSURE SWITCH

(Optional) Notifies or shuts down

the car wash in the event of a low

water fault - great for unstaffed

sites.

INLET WATER

SELECTION VALVE

(Optional) Use two water sources

with the same pump - select fresh,

RO, reclaim, or tempered water.

INTEGRATED ELECTRICAL

CONTROL BOX

UL approved enclosure, with easy

wire single control cable.

MANIFOLD WINGS

Available in sets of 4, for up to

12 total applications. Use with

quick change injectors, flow-thru

rinse valves, and duo-foam or

triple-foam manifolds.

FOAMING AIR OR FROST

PROTECTION WING

(Optional) Includes air valves and

air regulators.

PROPRIETARY

AIR-ACTUATED VALVE

Allows particulate in water stream

to pass through, preventing fail to

close errors. Offers enhanced de-

pendability over electric solenoid

valves.