How to work with solderless breadboards – Global Specialties PRO-S-LAB User Manual

Page 6

HOW TO WORK WITH SOLDERLESS BREADBOARDS

A solderless breadboard is an extremely useful device which

allows you to interconnect electronic components in an almost

endless variety of ways to produce working circuits. More

importantly, it makes it easy to modify or completely revise

these circuits quickly, and without use of any tools. And since it

eliminates the possibility of overheating and damaging them,

and it allows them to be used over and over.

Mechanically, the solderless breadboard is a set of formed

metal sockets inserted into a plastic housing which holds them

firmly in place. The pattern seen from the top is designed to

provide a useful combination of isolated tie points as well as

continuous bus structure. The isolated tie points serve as

discrete points in the circuit you are constructing, while the

busses serve, generally, to distribute power and provide

common ground points.

Solderless breadboards have a very long life expectancy if

treated properly. The most important thing to be aware of is the

size of the wire used; we recommend using #22 AWG solid wire

only. Wire which is too small may lead to poor or intermittent

connections. Wire which is too large may deform the internal

metal sockets to the point where they will not grip the proper

wire size any more, rendering the breadboard useless. A

second caution is to avoid soldering a wire which is inserted into

a solderless breadboard, as it may cause the plastic

surrounding the pin to melt, or may remove the temper from the

metal rendering it electrically unreliable.

4

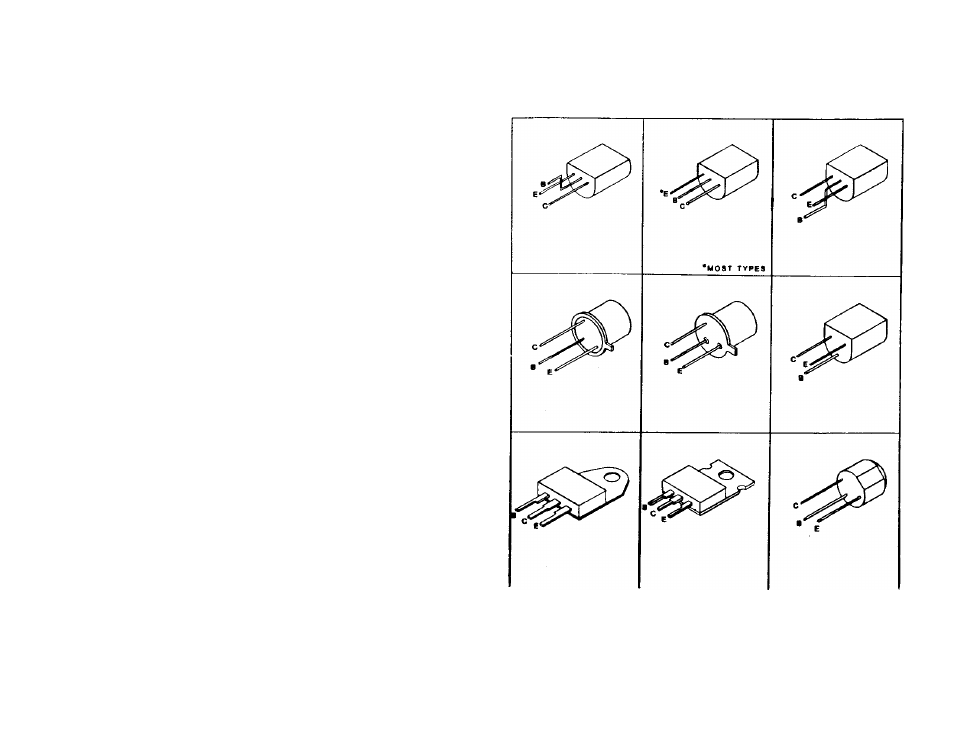

TRANSISTOR INDENTIFICATION

9