Pump operation, Typical manual dewatering installation, Stopping – BJM Pumps KZN(R)-F SERIES HEAVY DUTY AGITATOR TOP DISCHARGE Electric Submersible Pumps User Manual

Page 9

9

PUMP OPERATION

This pump is designed to handle dirty water that contains some

solids. It is not designed to pump volatile or flammable liquids. Do not attempt to pump

any liquids which may damage the pump or endanger personnel as a result of pump

failure.

Do not operate this pump where explosive vapors or

flammable material exist. Death or Serious injury will result.

TYPICAL MANUAL DEWATERING INSTALLATION

NOTE: Maximum recommended starts should not exceed 10 times per hour.

All KZN-F models are provided with a 50

’ (10m) power cord.

U

NEVER

U

splice the power

cable due to safety and warranty considerations. Always keep the lead end dry.

Note: 208V, 230V, 460V & 575V three phase units do not have a plug and have to

be provided separately.

Do not alter the length or repair any power cable with a splice. The

pump motor and cable must be completely waterproof. Damage to the pump or

personal injury may result from alterations.

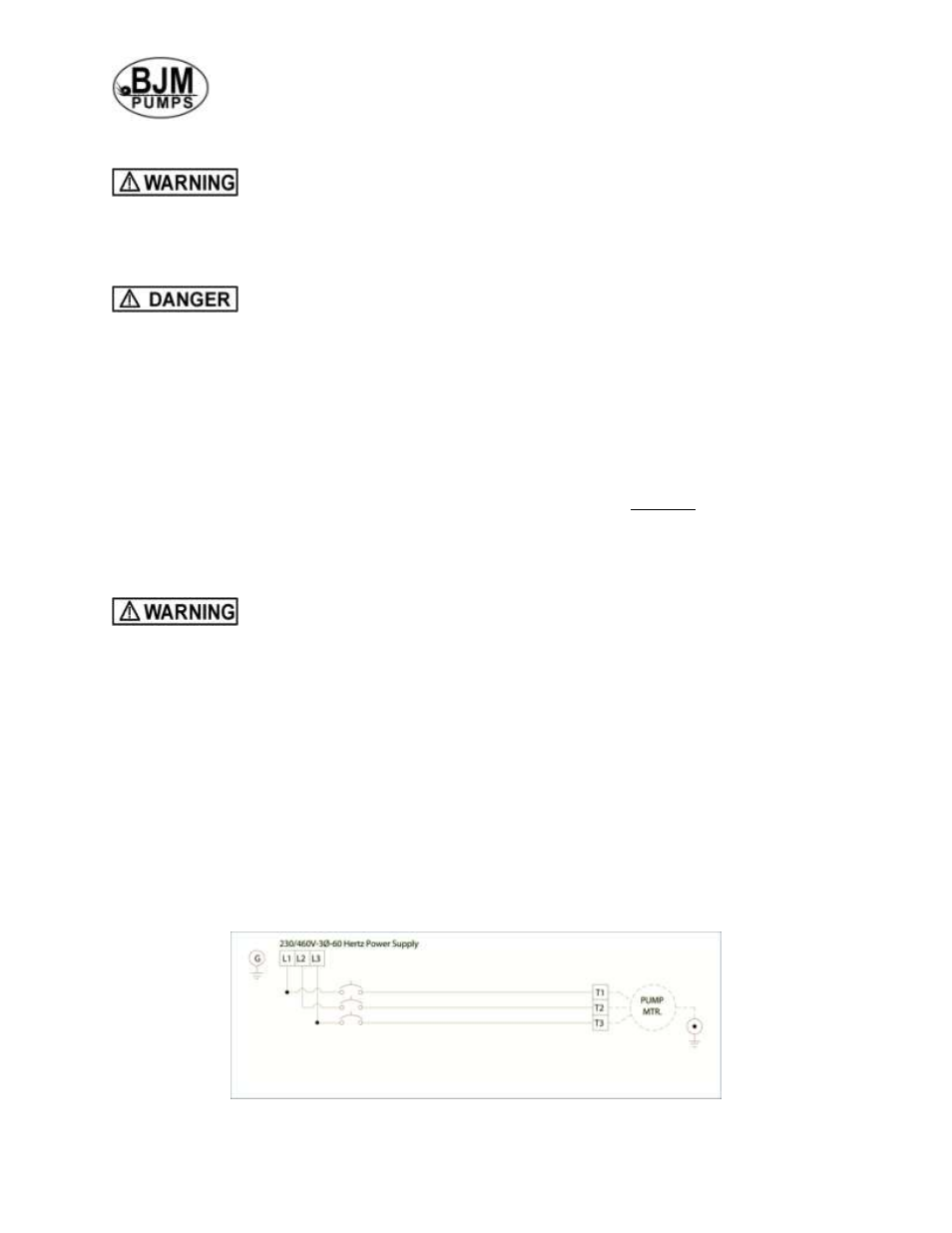

For manual operation: 208, 230, 460 & 575 volt: Attach the proper plug or connect

directly to the power source or control box. KZN-F model pumps are supplied with two

grounding wires; one green for grounding to the panel; the other is orange and is to be

used for grounding check systems or can be also connected to the grounding point on

the control. Check the direction of the rotation. Tilt the pump and start it. It should twist

in the opposite direction of the arrow (on pump). It is recommended that a Ground Fault

Interrupter (GFI) type receptacle (or equivalent) be used.

STOPPING

To stop the pump (manual and automatic mode), unplug it from the power source, turn

off the breaker, or turn the power source off (generator).

Typical 3 phase manual control 1