Changing mechanical seal cooling oil – BJM Pumps KZE550-575 User Manual

Page 15

14

Preventative maintenance should be performed to reduce the chance of

premature failure.

Worn impellers and lip seals should be replaced.

Cut or cracked power cables must be replaced. (Never operate a pump with a

cut, cracked or damaged power cable.)

Seal oil should be checked once per year.

Maintenance should always be done when taking a pump out of service before

storage.

1) Clean pump of dirt and other build up.

2) Check condition of oil around the shaft seals.

3) Check hydraulic parts: check for wear.

4) Inspect power cable. Make sure that it is free of nicks or cuts.

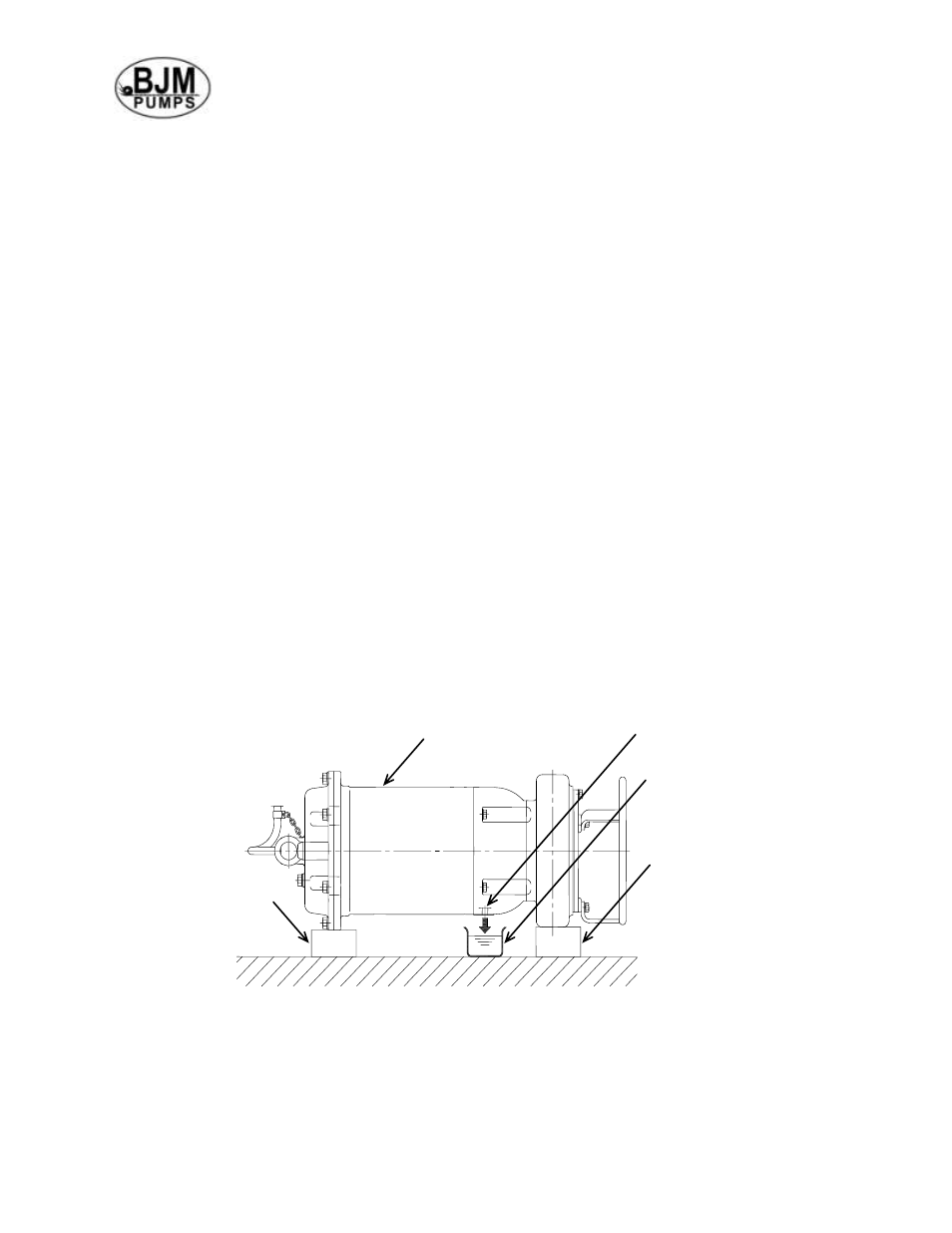

CHANGING MECHANICAL SEAL COOLING OIL

Changing the seal oil in the KZE Series pumps is very easy.

1) Disconnect the pump power cable from the power source.

2) Pull the pump from the sump and lay it on its side as shown in the illustration

below.

3) Remove the oil fill/drain screw, and drain the oil contents into a catch

container. If there was water or the oil appeared milky, the mechanical seal

should be inspected and possibly changed.

4) Place the pump back into an upright position.

5) Fill the proper and type of oil back into the seal chamber.

Body

Oil Plug Hole

Adequate Stand

Transparent Vessel

Adequate Stand