Installation application examples, Vac power input wiring, Relay input wiring – Flowline LC40, LC41 and LC42 Remote Controller User Manual

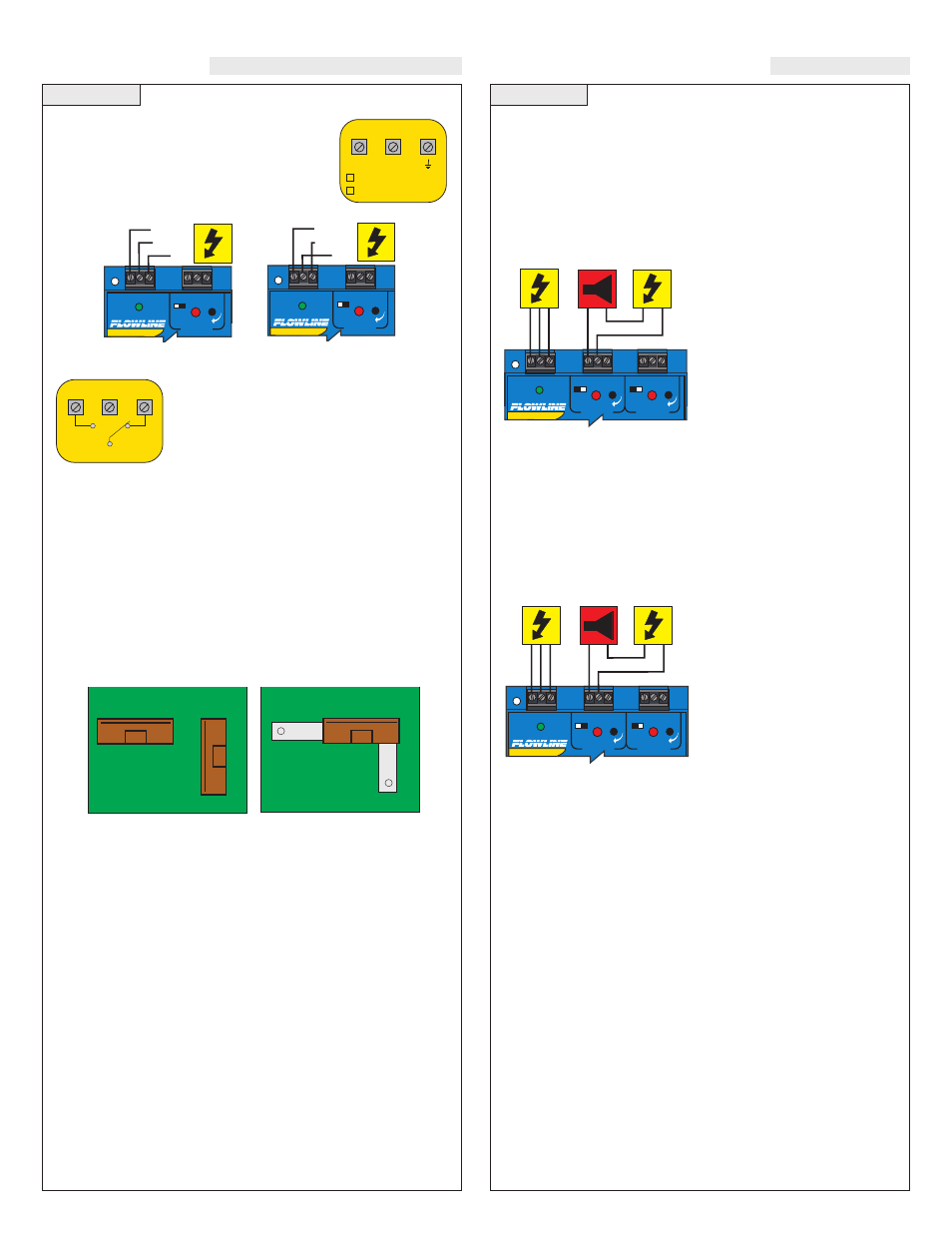

Page 5: Low level alarm, High level alarm, 120 vac, 240 vac

VAC Power Input Wiring:

Observe the POWER SUPPLY label on the LC40

series. The label identifies the power requirement

(120 or 240 VAC) and the terminal wiring. Note:

Polarity does not matter with the AC input termi-

nal.

Step Six

Step Seven

INSTALLATION

APPLICATION EXAMPLES

Relay Input Wiring

The relay is a single pole, double throw type rated

at 250 Volts AC, 10 Amps, 1/4 Hp. The two ter-

minal NO and NC (normally open and normally

closed) will be used in different applications.

Remember that the "normal" state is when the

relay coil is de-energized and the Red relay LED

is Off / de-energized.

Changing from 120 to 240 VAC

1. Remove the back panel of the controller and gently slide the printed

circuit board from the housing. Use caution when removing the PCB.

2. Located jumpers JW1, JW2 and JW3 on the PCB.

3. To change to 240 VAC, remove jumpers from JW1 and JW2 and

place a single jumper across JW3. To change to 120 VAC, remove

jumper JW3 and place jumpers across JW1 and JW2.

4. Gently return PCB into housing and replace back panel.

Low Level Alarm

The goal is to make sure that the liquid level does not fall below a cer-

tain point. If it does, an alarm is supposed to sound, alerting the oper-

ator of a low level condition.

If power is accidentally cut to the controller, the sensor's ability to

notify the operator of a low level condition could be lost. The system

must alert the operator not only to low liquid level, but to controller

power loss.

To do this, connect the hot lead of

the alarm to the NC side of the

relay terminal of the controller. If

power is lost, the relay will be de-

energized, and the alarm will

sound (if there is still power to the

alarm circuit itself). The alarm cir-

cuit should have a non-interrupt-

ible power supply or some other

indicator or backup alarm to warn

of a power failure in the alarm circuit.

In this application, the normal status if the sensor at the bottom if the

tank will be wet, and the relay will be energized holding the alarm cir-

cuit open. Both the relay LED and the Input LED will be on simulta-

neously, so for this application, Invert should be set to the Off position.

High Level Alarm

In the same manor, this system can be used to sound an alarm when

fluid reaches a high level, with just a change in the location of the sen-

sor and the setting of the Invert switch.

The alarm is still connected to the

NC side of the relay to allow for a

power failure alarm.

The sensor is normally dry. In this

condition, we want the relay to be

energized so the alarm does not

sound: i.e., the Red relay LED

should be on whenever the Input

LED is Amber. So we turn Invert

On. If the fluid level rises to the

high sensor point, the sensor goes on, the relay de-energizes, and the

alarm sounds.

INPUT

120 VAC, 50 - 60 Hz

240 VAC. 50 - 60 Hz

L1 L2 ( )

RELAY OUTPUT

250 VAC, 10A, 1/4 Hp

NO

NC

C

120 VAC

JWB

JWA

JWC

240 VAC

JWB

JWA

JWC

R E L A Y 1

R E L A Y 2

P O W E R

- +

- +

I N V E R T

D E L A Y

I N V E R T

D E L A Y

R E L A Y 1

R E L A Y 2

P O W E R

- +

- +

I N V E R T

D E L A Y

I N V E R T

D E L A Y

R E L A Y 1

P O W E R

- +

I N V E R T

D E L A Y

Ground

Neutral

Hot

R E L A Y 1

P O W E R

- +

I N V E R T

D E L A Y

Ground

Neutral

Hot