Troubleshooting guide, Enzx – EBARA ENZX User Manual

Page 7

Ebara Submersible Slurry Pump

ENZX

Operating, Installation and Maintenance

Troubleshooting Guide

If the fault cannot be remedied, please contact Ebara FHD customer service directly by phone: (803) 327-5005 or

e-mail: [email protected].

Ebara

Fluid Handling

www.pumpsebara.com

7

(803) 327-5005 • (803) 327-5097

(fax)

rev. 03/14

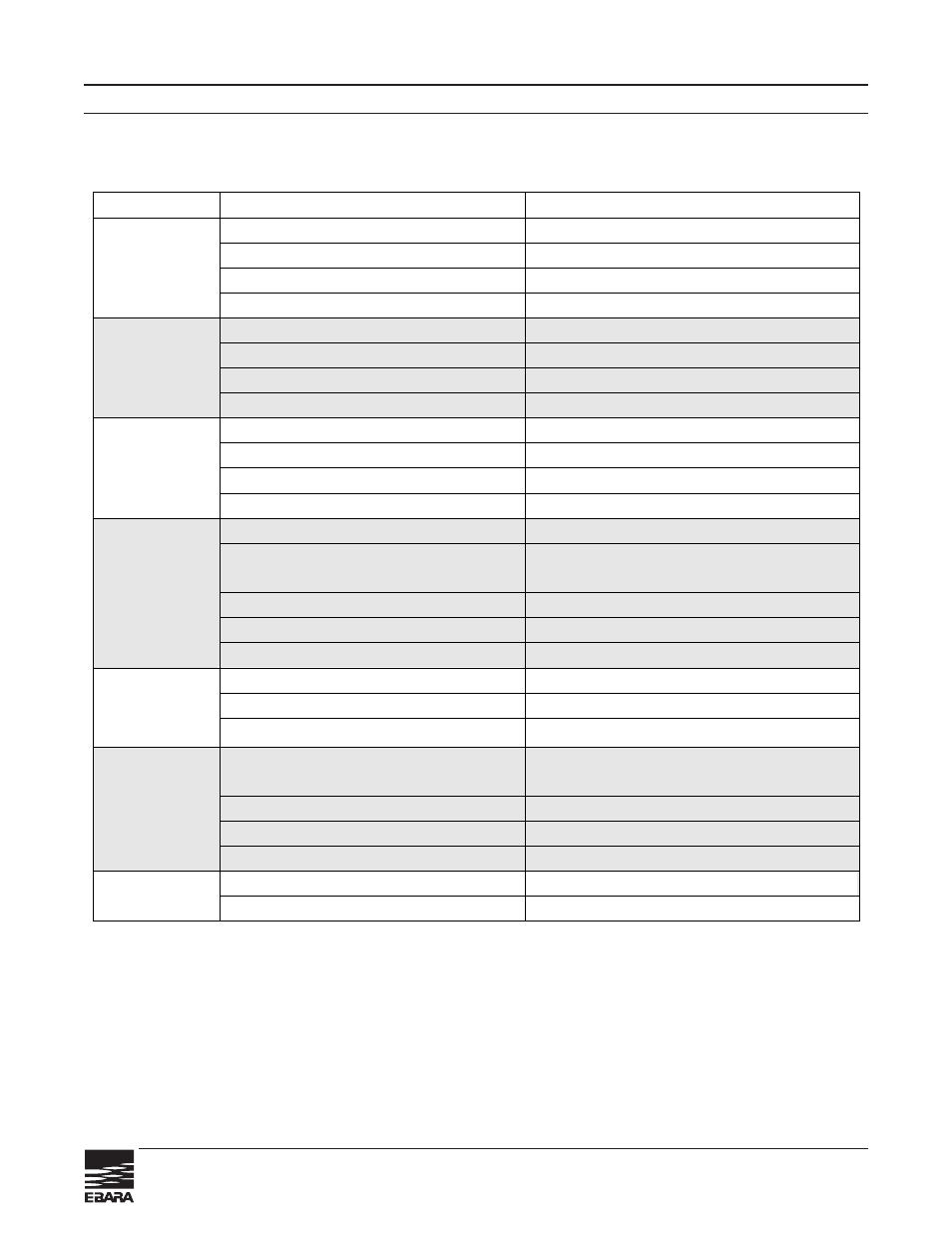

Faults

Problem

Solution

No liquid lifting

or deficient

1. Reverse rotation of motor

1. Change any two leads of the three phases

2. Pipe or impeller blocked

2. Clear suction area

3. Impeller drop down or damaged

3. Re-secure or change impeller

Uneven running

(Vibration)

1. Pump head too low or pump cavitation 1. Replace pump or reset valve

2. Impeller damaged

2. Replace impeller

3. Bearing damaged

3. Replace bearing

4. Impeller friction

4. Reset impeller gap

Insulation failure

1. Cable damaged

1. Replace cable and dry motor

2. Mechanical seal failure

2. Replace seal and dry motor

3. O ring failure

3. Replace O ring and dry motor

4. Water into cable

4. Replace cable and dry motor

1. The pump is locked

1. Free impeller

2.Medium density and viscosity is

excessive

2. Adjust medium density and viscosity.

3. Bearing damaged

3. Replace bearing

4. Working voltage is too low

4. Reset voltage

Sudden

current

drop

1. Pipe or pump blocked

1. Cleaning pump or pipe

2. Water level is too low

2. Filling medium

3. Impeller damaged

3. Replace impeller

Thermal

protection

(WC) alarm

1. Motor out of water

1. Reset pump installation or install cooling

device

2. Voltage low

2.Reset voltage

3. Bearing damaged

3. Replace bearing

4.Trouble with cooling device

4. Clean cooling device

Leak protection

˄

XLǃJH˅alarm

1. Mechanical seal failure

1. Replace seal and dry motor

2. O ring failure

2. Replace O ring and dry motor

Current

excessive or

motor

temperature

too high