Evmu, Ebara stainless steel vertical multistage, Instructions and operation – EBARA EVMU User Manual

Page 41: Ebara, Rev. 11/10

Ebara Stainless Steel Vertical Multistage

EVMU

Instructions and Operation

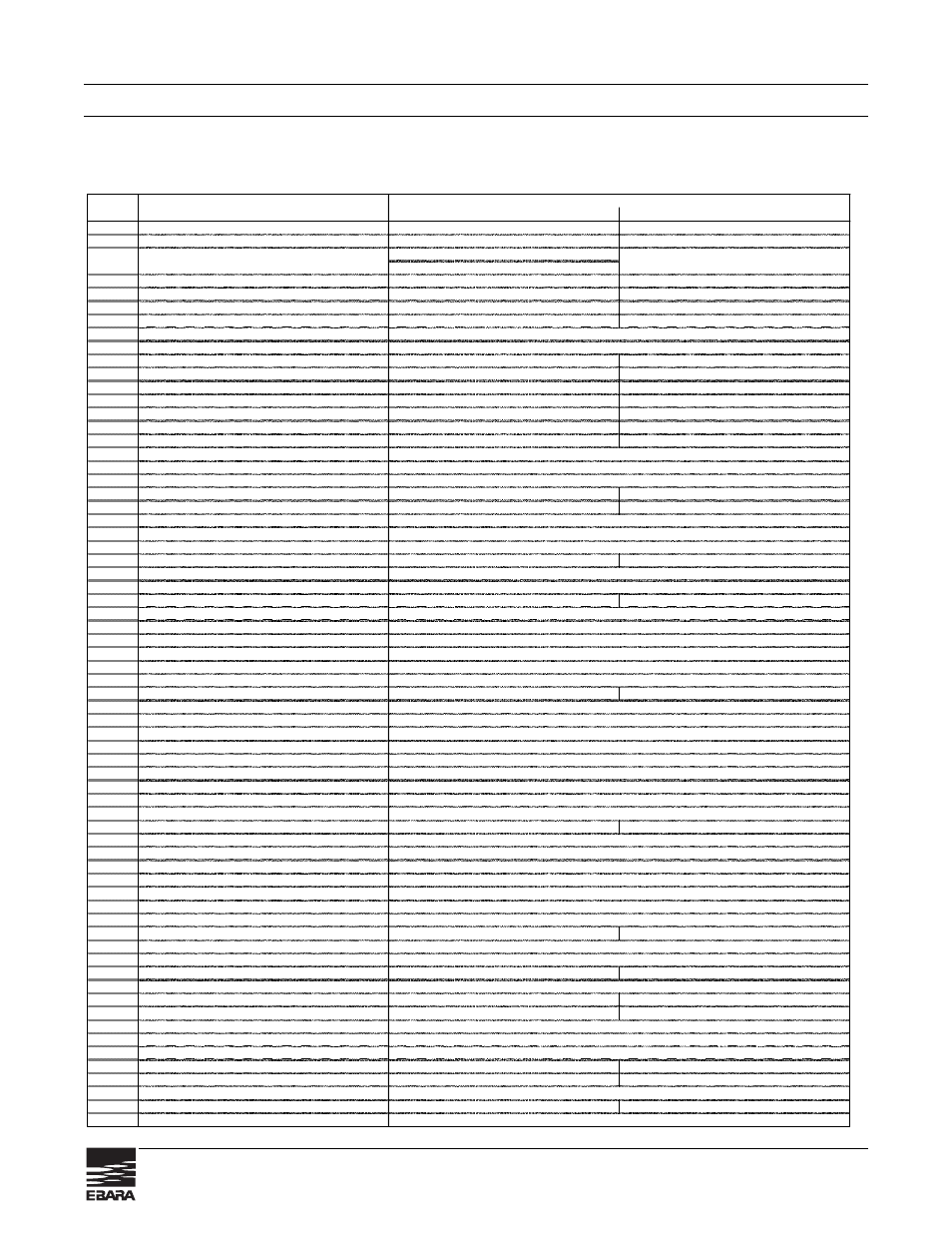

Sectional View – part reference

Model EVMUG45 EVMUG4

EVMUL45 EVMUL64

Ebara

Fluid Handling

www.pumpsebara.com

41

(t) 803 327-5005 • (f) 803 327-5097

rev. 11/10

MUL

V

E

MUG

V

E

005-2

Stage c as ing

6

1

3

I

S

I

A

4

0

3

I

S

I

A

005-4

T op c as ing

6

1

3

I

S

I

A

4

0

3

I

S

I

A

16bar:Cas t iron EN-GJ L-250

25bar:Cas t iron EN-GJ S-400-15

007

Outer s leeve

6

1

3

I

S

I

A

4

0

3

I

S

I

A

6

1

3

I

S

I

A

+

5

1

-

0

0

4

-

S

J

G

-

N

E

n

o

r

i

t

s

a

C

5

1

-

0

0

4

-

S

J

G

-

N

E

n

o

r

i

t

s

a

C

r

e

v

o

c

g

n

i

s

a

C

1

1

0

012

Suc tion c over

6

1

3

I

S

I

A

4

0

3

I

S

I

A

021

Impeller

6

1

3

I

S

I

A

4

0

3

I

S

I

A

031

Shaft

AISI316

)

g

n

i

l

p

u

o

c

(

y

e

K

1

-

9

3

0

C45

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

l

a

e

s

l

a

c

i

n

a

h

c

e

m

(

e

v

e

e

l

s

t

f

a

h

S

1

-

3

4

0

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

e

g

a

t

s

(

e

v

e

e

l

s

t

f

a

h

S

2

-

3

4

0

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

r

e

p

p

u

/

g

n

i

r

a

e

b

(

e

v

e

e

l

s

t

f

a

h

S

3

-

3

4

0

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

r

e

w

o

l

/

g

n

i

r

a

e

b

(

e

v

e

e

l

s

t

f

a

h

S

4

-

3

4

0

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

p

o

t

(

e

v

e

e

l

s

t

f

a

h

S

5

-

3

4

0

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

n

o

i

t

c

u

s

(

e

v

e

e

l

s

t

f

a

h

S

6

-

3

4

0

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

g

n

i

r

a

e

b

m

o

t

t

o

b

(

e

v

e

e

l

s

t

f

a

h

S

7

-

3

4

0

044-1

Bearing s leeve

(s tage)

T ungs ten c arbide

e

d

i

b

r

a

c

n

e

t

s

g

n

u

T

)

g

n

i

r

a

e

b

m

o

t

t

o

b

(

e

v

e

e

l

s

g

n

i

r

a

e

B

2

-

4

4

0

045

Adjus ting ring

C40

047

Split ring retainer

6

1

3

I

S

I

A

4

0

3

I

S

I

A

048

Fric tion nut

6

1

3

I

S

I

A

4

0

3

I

S

I

A

051

Bearing hous ing

Cas t iron EN-GJ L-200

)

e

g

a

t

s

(

g

n

i

r

a

e

B

1

-

2

5

0

T ungs ten c arbide

)

m

o

t

t

o

b

(

g

n

i

r

a

e

B

2

-

2

5

0

T ungs ten c arbide

053

Bus h holder

6

1

3

I

S

I

A

4

0

3

I

S

I

A

056

Ball bearing

-

070-1

Bearing holder

AISI304

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

g

n

i

r

a

e

b

m

o

t

t

o

b

(

r

e

d

l

o

h

g

n

i

r

a

e

B

2

-

0

7

0

081

Bus h

PT FE(alloy)

107

W ear ring

AISI316+PT FE

6

1

3

/

M

P

F

/

n

o

b

r

a

C

/

C

i

S

y

'

s

s

a

e

g

d

i

r

t

r

a

C

l

a

e

s

l

a

c

i

n

a

h

c

e

M

1

1

1

)

r

e

t

u

o

(

g

n

i

r

-

O

1

-

5

1

1

FPM

)

e

g

a

t

s

(

g

n

i

r

-

O

2

-

5

1

1

FPM

120-1

T ie-rod bolt

Zinc ate s teel with 6.8 s trength c las s ISO 898/1

120-2

Stac k bolt

6

1

3

I

S

I

A

4

0

3

I

S

I

A

6

0

5

3

O

S

I

0

7

-

2

A

l

e

e

t

s

s

s

e

l

n

i

a

t

S

)

l

a

e

s

l

a

c

i

n

a

h

c

e

m

(

t

l

o

B

3

-

0

2

1

6

0

5

3

O

S

I

0

7

-

2

A

l

e

e

t

s

s

s

e

l

n

i

a

t

S

)

r

e

v

o

c

g

n

i

s

a

c

(

t

l

o

B

4

-

0

2

1

1

/

8

9

8

O

S

I

s

s

a

l

c

h

t

g

n

e

r

t

s

8

.

8

h

t

i

w

l

e

e

t

s

e

t

a

c

n

i

Z

)

e

d

i

s

-

M

g

n

i

l

p

u

o

c

(

t

l

o

B

5

-

0

2

1

1

/

8

9

8

O

S

I

s

s

a

l

c

h

t

g

n

e

r

t

s

8

.

8

h

t

i

w

l

e

e

t

s

e

t

a

c

n

i

Z

)

e

d

i

s

-

P

g

n

i

l

p

u

o

c

(

t

l

o

B

6

-

0

2

1

1

/

8

9

8

O

S

I

s

s

a

l

c

h

t

g

n

e

r

t

s

8

.

8

h

t

i

w

l

e

e

t

s

e

t

a

c

n

i

Z

)

g

n

i

r

a

e

b

(

t

l

o

B

7

-

0

2

1

1

/

8

9

8

O

S

I

s

s

a

l

c

h

t

g

n

e

r

t

s

8

.

8

h

t

i

w

l

e

e

t

s

e

t

a

c

n

i

Z

)

g

n

i

s

u

o

h

g

n

i

r

a

e

b

(

t

l

o

B

8

-

0

2

1

6

0

5

3

O

S

I

0

7

-

2

A

l

e

e

t

s

s

s

e

l

n

i

a

t

S

)

g

n

i

r

a

e

b

m

o

t

t

o

b

(

t

l

o

B

9

-

0

2

1

6

0

5

3

O

S

I

0

7

-

2

A

l

e

e

t

s

s

s

e

l

n

i

a

t

S

)

d

n

e

t

f

a

h

s

(

t

l

o

B

2

1

-

0

2

1

2

/

8

9

8

O

S

I

s

s

a

l

c

h

t

g

n

e

r

t

s

S

6

h

t

i

w

l

e

e

t

s

e

t

a

c

n

i

Z

)

t

l

o

b

d

o

r

-

e

i

t

(

t

u

N

1

-

8

2

1

4

0

3

I

S

I

A

)

t

l

o

b

k

c

a

t

S

(

t

u

N

2

-

8

2

1

129

Bearing nut

(c oupling)

Carbon s teel

6

0

5

3

O

S

I

0

7

-

2

A

l

e

e

t

s

s

s

e

l

n

i

a

t

S

)

l

a

e

s

l

a

c

i

n

a

h

c

e

m

(

w

e

r

c

S

1

-

0

3

1

6

0

5

3

O

S

I

0

7

-

2

A

l

e

e

t

s

s

s

e

l

n

i

a

t

S

)

d

r

a

u

g

g

n

i

l

p

u

o

c

(

w

e

r

c

S

2

-

0

3

1

6

0

5

3

O

S

I

0

7

-

2

A

l

e

e

t

s

s

s

e

l

n

i

a

t

S

)

l

a

e

s

l

a

c

i

n

a

h

c

e

m

(

w

e

r

c

S

3

-

0

3

1

5

/

8

9

8

O

S

I

H

5

4

s

s

a

l

c

h

t

g

n

e

r

t

S

)

n

i

p

g

n

i

l

p

u

o

c

(

w

e

r

c

S

4

-

0

3

1

)

t

f

a

h

s

(

n

i

P

1

-

1

3

1

CF35SMnPb10

)

t

l

o

b

d

o

r

-

e

i

t

(

r

e

h

s

a

W

1

-

5

3

1

Zinc ate s teel

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

t

l

o

b

k

c

a

t

S

(

r

e

h

s

a

w

g

n

i

r

p

S

2

-

5

3

1

l

e

e

t

s

e

t

a

c

n

i

Z

)

e

d

i

s

-

M

t

l

o

b

g

n

i

l

p

u

o

c

(

r

e

h

s

a

w

g

n

i

r

p

S

3

-

5

3

1

135-4

Spring was her

(bearing)

Zinc ate s teel

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

d

n

e

t

f

a

h

s

(

r

e

h

s

a

w

g

n

i

r

p

S

5

-

5

3

1

136

Bearing was her

(c oupling)

Carbon s teel

137-1

Shaft end s leeve

6

1

3

I

S

I

A

4

0

3

I

S

I

A

137-2

Shaft end s leeve

6

1

3

I

S

I

A

4

0

3

I

S

I

A

140-1

Coupling upper half

Steel (36SMnPb14)

140-2

Coupling lower half

Steel (36SMnPb14)

163

Motor s tool

Cas t iron EN-GJ L-200

M

P

F

/

6

1

3

I

S

I

A

M

P

F

/

4

0

3

I

S

I

A

)

g

n

i

r

l

a

e

s

h

t

i

w

(

g

u

l

p

t

n

e

V

2

1

2

M

P

F

/

6

1

3

I

S

I

A

M

P

F

/

4

0

3

I

S

I

A

)

g

n

i

r

l

a

e

s

h

t

i

w

(

g

u

l

P

7

1

2

245

Coupling guard

AISI304

6

1

3

I

S

I

A

4

0

3

I

S

I

A

)

p

o

t

(

g

n

i

r

-

C

1

-

4

7

2

613

Pump flange

C40

E

M

A

N

T

R

A

P

.

O

N

MAT ERIAL

006

Bottom c as ing

Cas t AISI316 (G-X6CrNiMo18 0)

(For reference only. See pricing for part availability.)