Gas connection, Boiler exhaust connection, Warning – AAON LL-540 User Manual

Page 29: Caution

29

Gas Connection

For LL Series outdoor mechanical units with

boiler systems, size gas piping to supply the

unit with proper pressure when all gas

consuming

devices

in

the

building

connected to the same gas system are

operating. The maximum gas train inlet

pressure for all boiler sizes is 5 psig. The

minimum gas train inlet pressure for the 500

MBH boiler is 5 inches of water column,

and for all other boilers, 7 inches of water

column.

Carefully consider all current and future gas

usage. Table 3 details the input rate for each

boiler unit.

Gas connection sizes are listed on the unit

rating sheet.

Table 3 - Boiler Rated Input Capacity

Boiler Size

Rated Capacity (CFH)*

Natural

LP/Propane

500 MBH

500

200

750 MBH

750

300

1000 MBH

1000

400

1500 MBH

1500

600

*Note: Rating is for sea level conditions.

For additional information regarding the gas

piping

connection,

see

the

Thermal

Solutions Boiler “Installation, Operating,

and Service Instructions” that are included

with the unit.

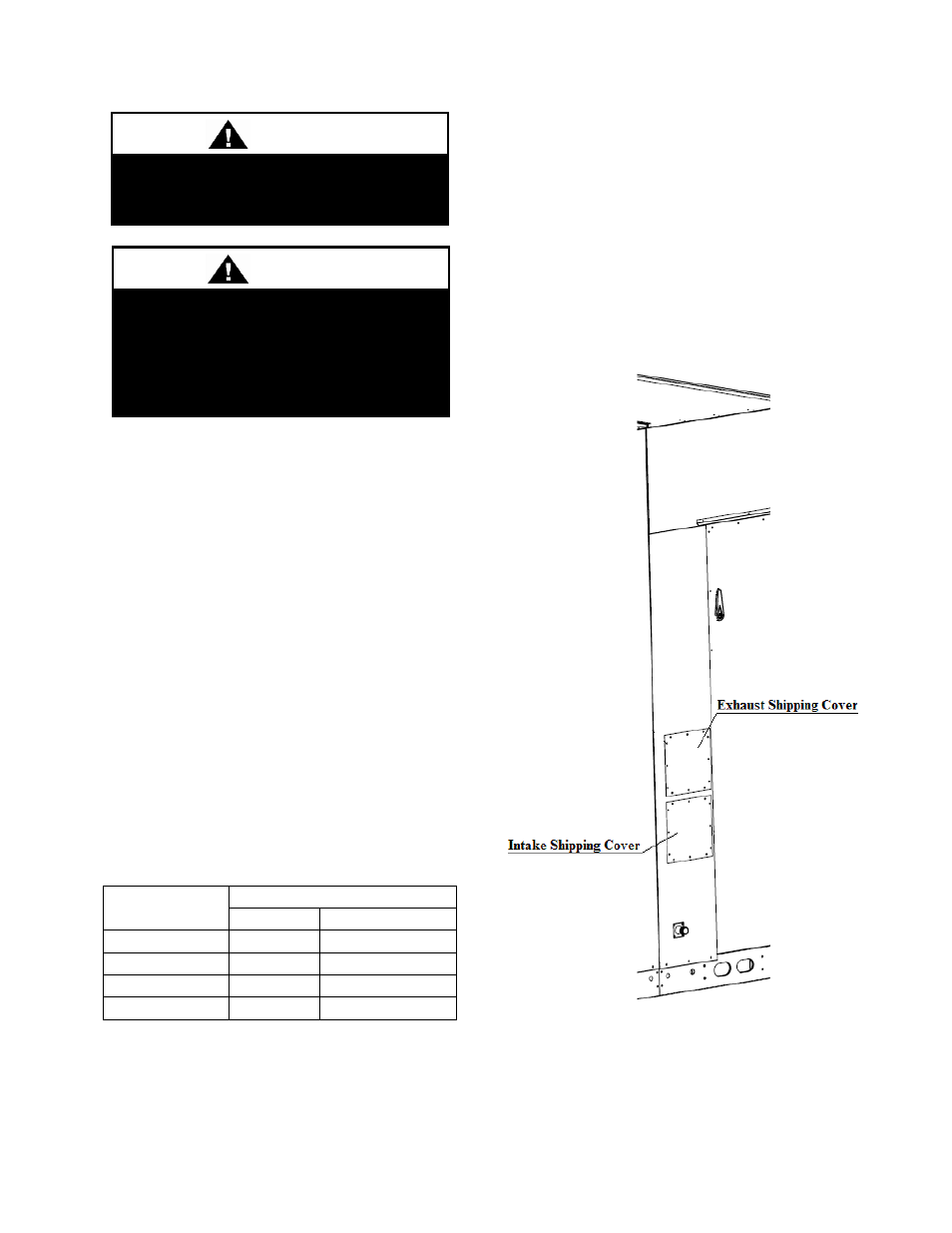

Boiler Exhaust Connection

In addition to gas connection installation,

each boiler requires installation of the

exhaust vent piping and inlet vent hood. The

exhaust panel with chimney cutout is

removed for shipping, and replaced with a

shipping cover.

Figure 7 - Boiler Vent Shipping Covers

Remove the shipping cover and attach the

exhaust panel shipped with the unit. When

the exhaust panel is securely fastened with

Boilers must be operated only with

liquid flowing through the boiler.

WARNING

Installing Contractor is responsible

for proper sealing of the water piping

entries into the unit Failure to seal the

entries may result in damage to the

unit and property.

CAUTION