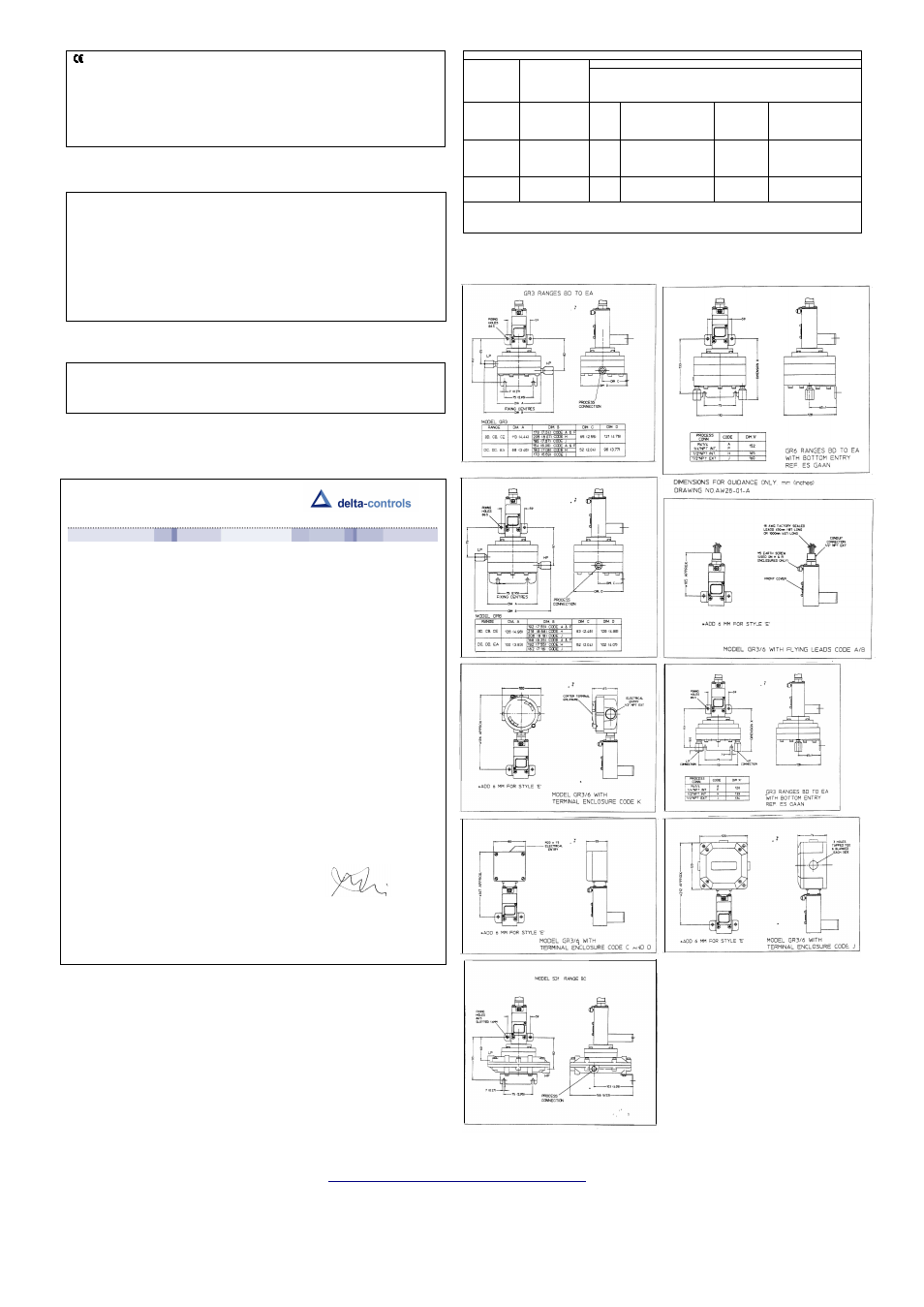

Fig 6, Fig 7, Fig 8 – Delta Controls GR3_6 User Manual

Page 2: Fig 11, Fig 13, Declaration of conformity

TABLE A – MICROSWITCH RATINGS

SWITCH

CODE

(type)

UL/CSA

MICROSWITCH

RATING (Resistive)

*See Note

IEC 947-5-1/EN 60947-5-1 RATING

Designation

& Utilization

Category

VA

Uimp

Ui

RATING

(Ie/Ue)

MAKE

BREAK

HS, HD, HR

11A @ 110/250 VAC

0.8kV

250V

0.6/0.3A @

120/240 VAC

AC14/D300

AC

432

72

5/0.5 @ 30/125 VDC

0.22/0.1A @

125/250VDC

DC13/R300

DC

28

28

HP, HQ, HT

5A @ 250 VAC

0.5kV

250V

0.6/0.3A @

120/240 VAC

AC14/D300

AC

432

72

2A @ 30 VDC

0.22/0.1A @

125/250VDC

DC13/R300

DC

28

28

HV, HW, HY

1A @ 125 VAC

0.5kV

120V

0.3A @ 120 VAC

AC14/E150

AC

216

36

*1A @ 30 VDC

The electrical rating is dependent on the microswitch fitted to the switch. The electrical rating is defined by each approval that the

microswitch complies with and is shown on the product nameplate, ie UL/CSA or IEC. It should be noted that the switch must be

used within the electrical rating specified from the approval you require. Table A lists the actual IEC ratings against the Designation

and Utilisation Category marked on the nameplate. If in doubt, seek guidance from factory.

Low Voltage Directive (LVD) – 2006/95/AC. Products with enclosure codes ‘W’ and ‘A’ supplied CE-

marked must be installed and used in accordance with the main instructions and this addendum supplied

with each product. Products rated lower than 50V ac and 75 V dc are outside the scope of the LVD. The

LVD does not apply to products with enclosure codes ‘H’ and ‘R’, for use in hazardous areas. Such

products are covered by the Explosive Atmospheres Directive ATEX – 94/9/EC and when CE-marked will

indicate compliance with this directive alone. The following directives do not apply to switch products

manufactured by Delta Controls:

Electromagnetic Compatibility EMC – 2004/08/EC.

Machinery Safety Directive MSD – 2006/42/EC.

WIRING

Junction box cable glands and adaptors. Optional Junction box code ‘C’ is supplied with an M20 x 1.5

tapped hole blanked with a red plug. Discard the red plug and fit a suitable proprietary brass or nylon M20

cable gland with thread length of 10 mm. Fit a fibre washer to the outside. See diagram 1.

Alternately the junction box may be supplied from the factory with a threaded adaptor ready to accept the

customer’s gland or conduit system.

Alternatives:

1) a metal or nylon adaptor may be used to accommodate other sizes of gland eg NPT, or conduit system.

See diagram 2.

Earthing / grounding – Use earthing point provided inside the junction box (when fitted). The user must

make suitable local earthing arrangement, if required, to ensure that metal glands / adaptors are earthed.

Pollution degree – all products are suitable for use in pollution degree 3.Ref EN60947-5-1

Electrical Isolation – these products are not suitable for electrical isolation. Always isolate circuit

separately to carry out any electrical work.

Fig 5

Fig 6

Fig 7

Fig 8

Fig 9

Fig 10

Fig 11

Fig 12

Fig 13

In the interest of development and improvement Delta Controls Ltd, reserve the right to amend without notice,

details contained in this publication. No legal liability will be accepted by Delta Controls Ltd, for any errors,

omissions or amendments.

YOUR TRUSTED PARTNER IN PROCESS INSTRUMENTATION

DELTA CONTROLS LIMITED, ISLAND FARM AVENUE, WEST MOLESEY, SURREY KT8 2UZ

T

+44 (0) 208 939 3511

F

+44 (0) 208 783 1163

E

W

www.delta-controls.com

Stock No: 002522/GR3

Registered Office Registered in England No 5369683

Declaration of Conformity

We: Delta Controls Ltd

Island Farm Avenue

West Molesey

Surrey, UK

KT8 2UZ

As the manufacturers of the apparatus listed, declare under our sole responsibility that the products

listed below:

Pressure, Pressure Difference, Temperature & Flow switches series “W” or “A”:

201, 202, 203, 281, 204, 207, 208, 209, 231, 232, 233, 234, S21, S22, S24, GR2, GR4, VM2, VM4.

301, 303, 304, 381, 384, 306, 386, 310, 316, S31, S34, GR3, GR6.

721, 731, 771, 722, 732, 772, 723, 733, 773, 781, 734, 774, 741, 742, 743, 744, S71, GR7.

131.

To which this declaration relates are in conformity with the following relevant standards or parts

thereof:

EN 60947-1 :1992

Low voltage switch gear and control-gear-general rules.

EN 60947-5-1:1992

Low voltage switch gear and control-gear-control circuit devices and switching

elements.

EN 60529: 1991 Specification for classification of degrees of protection provided by enclosures.

EN 60950:1992 Safety of information technology equipment including electrical business equipment:

section 2.5.

BS 6134:1991

Specification for pressure and vacuum switches.

And thereby conforms to the requirements of the Low Voltage Directive 73/23/EC amended by

93/68/EEC.

Signed:

………………….

R. Harrison

Managing Director

Original dated 22

nd

June 2000

Rev. B dated 12

th

August 2009