Delta Controls HT01 User Manual

Page 2

IOM-SENTRY-Ex-A : OCT 2012

www.delta-controls.com

Wiring (continued...)

1 or 2 electrical entries are provided, into which

cable glands can be assembled. The thread type

and size is marked on the enclosure, just below the

connection. Select a suitable cable gland which will

maintain the IP rating of the instrument.

USE ONLY SUITABLY ZONE 1 CERTIFIED

CABLE GLANDS OR STOPPING PLUGS.

CABLE TEMPERATURES MAY EXCEED 80°C.

USE

ONLY

CABLES

WITH

SUITABLE

OPERATING TEMPERATURE RANGE.

Use only certified adaptors for Zone 1/Div 1.

Unused entries are to be fitted with suitably certified

stopping plugs.

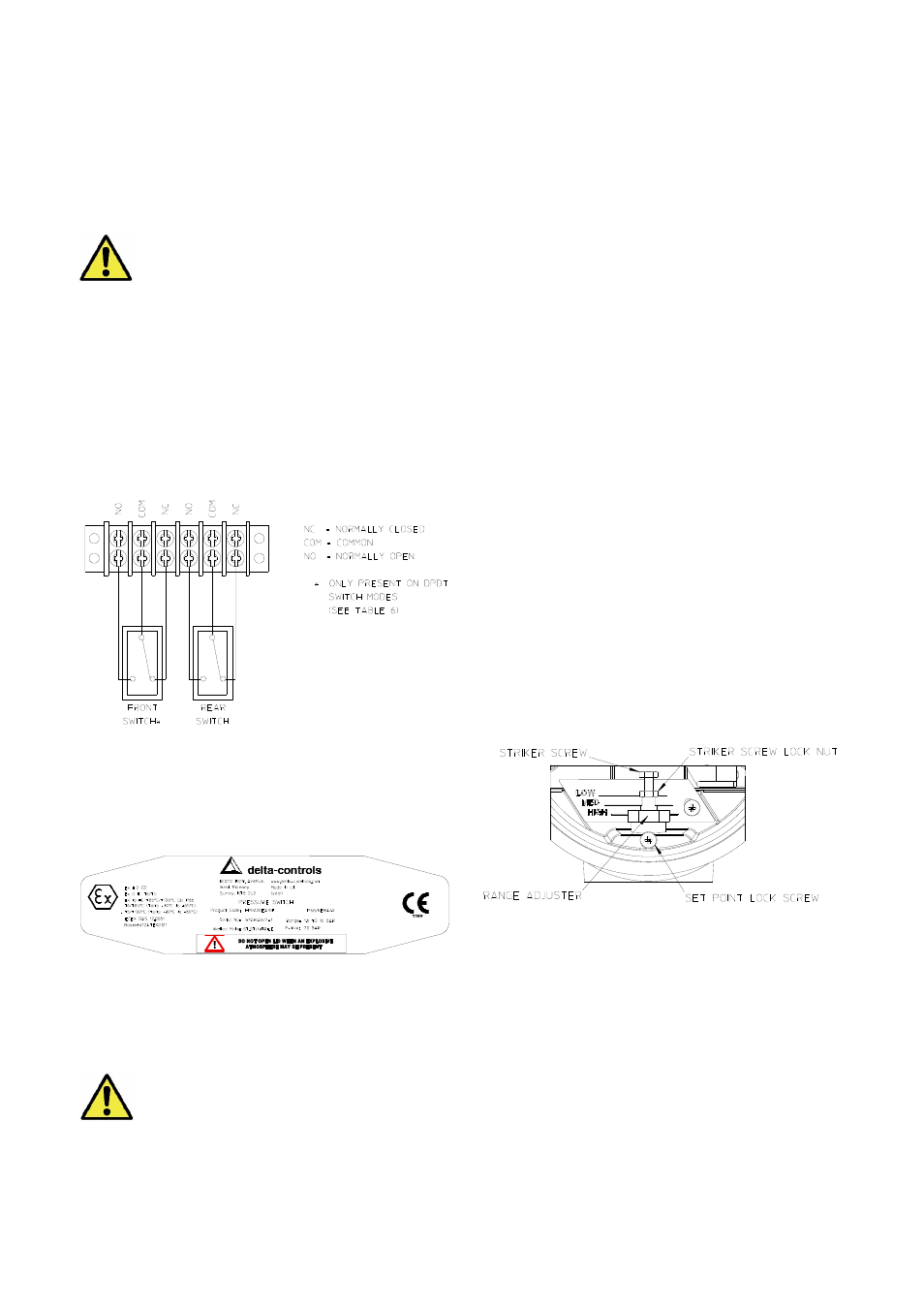

The three switch terminals are clearly marked

“NORMALLY CLOSED”, “NORMALLY OPEN” and

“COMMON”.

The following diagram can be used as a guide for

wiring.

OPERATION

Adjustments

Pressure and Temperature Switches are supplied

calibrated at the midpoint of their range and to a

falling pressure or temperature unless otherwise

specified.

To re-calibrate:

1. Isolate the instrument from the process and

power.

2. Slacken the set point lock screw.

3. Using a suitable spanner, rotate the range

adjuster clockwise to increase the set point and

counter-clockwise to decrease the set point.

4. Tighten the set point lock screw.

5. Close the instrument lid and tighten lid lock screw

Note: For accurate setting of Pressure and

Differential Pressure models, a suitable pressure

gauge must be used in conjunction with the above

procedure. Do not attempt to set the switch outside

the scale limits. For Temperature models a suitable

calibrated temperature source should be used.

Though the unit may be set anywhere within its

range, for optimum performance, it is good practice

to have a set point value between 25% and 75% of

span.

The striker screw and lock nut are factory set and

should not be adjusted. Should these parts be

accidentally loosened, please contact Delta for

assistance.

Insert bare wires fully into the terminal block and tighten

securely. Keep wiring tails to a minimum and check that

wires do not interfere with the operating mechanism. Use

the earthing / grounding points provided.

BEFORE CLOSING THE LID:

ENSURE WIRE IS CLEAR OF ALL

MOVING PARTS.

ENSURE THAT WIRES DO NOT

TOUCH THE LID AS IT IS CLOSED.

Close the lid, being careful not to trap any wires in

doing so. Securely tighten the M3 lid locking screw

set provided using a 1.5mm hex key.

Each instrument if supplied with a label indicating

product description, product code, approvals, etc, as

shown in the example below.

Example label:

MAINTENANCE

Inspections should be carried out at quarterly to

yearly

intervals

depending

upon

operating

conditions. Isolate the unit from process and power

and remove the lid. Check all terminals for

tightness. Check that cable tails are not fouled or

chafed. Check for internal condensation. Check

that the gasket is seated properly in the lid recess

and is not worn. Keep the enclosure and lid clear of

dust build up. It is recommended that instruments

used to provide an alarm are operated periodically to

ensure they are functioning correctly. If further

maintenance is required seek advice from DELTA

CONTROLS

before

attempting

repair

or

replacement of parts.