Flexibility, Ondemand operation, Simplicity – ClimaCool UCH SHC onDEMAND Simultaneous Heating and Cooling Heat Recovery User Manual

Page 4: Dramatic energy savings, Compact, Ultimate efficiency, True redundancy, Source load cooling load heating

Load Hot

Loop

Load Cold

Loop

Flexibility

The 6 header design can be applied with

cooling towers, geothermal (ground and lake) loops,

or hybrid systems for true system flexibility. Cooling,

heating and source piping configuration is available

on same or opposite ends which allows for numerous

piping layouts. Bank sizes range from 30 to 1,000 tons

to ensure load demands are met efficiently.

onDEMAND Operation

Allows any module to

be indexed for heating or cooling regardless of its

position in the bank, providing optimum module/

compressor run time equalization.

Simplicity

6 header design simplifies installation,

design and controls. Simultaneously, the SHC satisfies

required heating and cooling demands without the

use of inter-module/external header isolation valves,

controls, associated logic, piping or wiring.

Dramatic Energy Savings

Eliminate the need

for separate heating and cooling systems thus saving

installation cost, overall operating cost, reducing

physical footprint while potentially lowering system

energy costs by more than 50% when compared to

traditional boiler/chiller systems.

Compact

No more need for bulky chiller systems

and large boiler room equipment. The SHC provides

the functionality of both in a minimal footprint. Patent

pending 6 header design eliminates the required space

between and external to the modules. This creates the

smallest system operating footprint when compared

to a typical simultaneous system and allows for same

end piping connections. Modular 6 pipe design allows

access through standard 36” doorways and onto

typical freight elevators.

Ultimate Efficiency

The CoolLogic Control

System provides advanced algorithms for maintaining

precise leaving chilled and hot water temperatures.

Integral motorized valves allow for variable pumping

on heating, cooling and source water loops. High

efficiency design offers cooling efficiencies up to 25

EER and heating efficiencies up to 5 COP.

True Redundancy

Separate module electrical

feeds provide true electrical redundancy. Integral

motorized isolation valves and dual independent/

refrigerant circuits per module provide true

mechanical redundancy.

Source

Loop

Load Hot

Loop

Load Cold

Loop

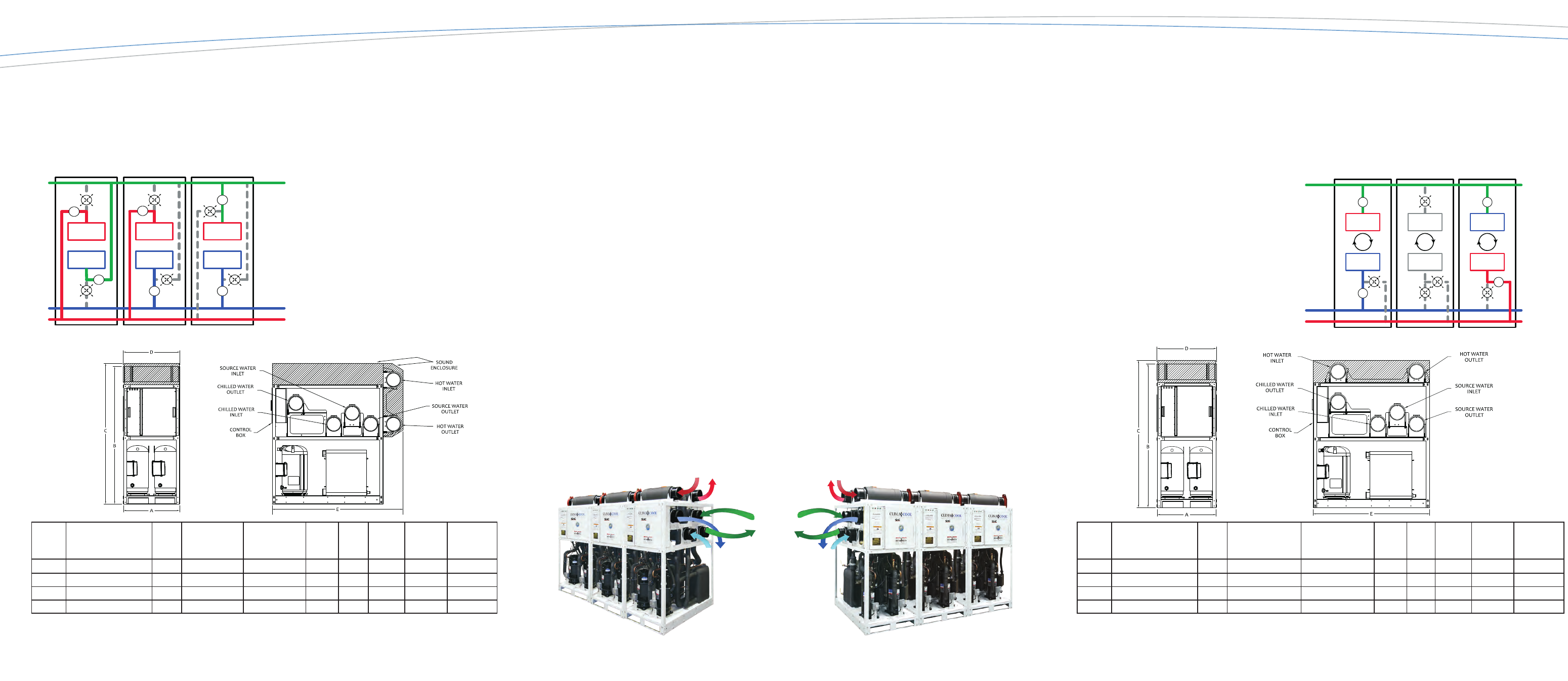

Produce heating, cooling and hot water from a single unit

• Simultaneous heating/cooling available from each module

• Provides hot water, as high as 135

o

F, utilizing R-410A refrigerant and 165

o

F utilizing R-134a refrigerant

• Built in modulating head pressure control

Use free heat to reduce energy consumption

Heat Recovery Model

Figure shows a bank of three modules:

Module 1 in Heating

Module 2 in Heating and Cooling

Module 3 in Cooling

MODEL

UCH

VOLTAGE

A

UNIT

WIDTH

(in.)

B

HEIGHT WITHOUT

SOUND ENCLOSURE

(in.)

C

HEIGHT WITH

SOUND ENCLOSURE

(in.)

D

HEADER

WIDTH

(in.)

E

UNIT

DEPTH

(in.)

UNIT

WEIGHT

1

(lb.)

OPERATING

WEIGHT

2

(lb.)

HEADER

CONNECTION

SIZE

3

(in.)

030

208/230/460/575/3/60

34

78 7/8

80

34 1/4

67 3/4

1530

1850

6

050

208/230/460/575/3/60

34

78 7/8

80

34 1/4

67 3/4

2150

2460

6

070

208/230/460/575/3/60

34

78 7/8

80

34 1/4

67 3/4

2400

2710

6

085

208/230/460/575/3/60

34

82 7/8

84 7/8

34 1/4

79 1/4

2850

3350

8

Notes:

1. Unit shipping weight includes refrigerant charge, compressor oil and packaging.

2. Operational weight includes refrigerant charge, compressor oil and water.

3. The model UCH085 cannot be directly coupled with model UCH030, 050 or 070 due to differences in header and frame size.

V

V

V

V

V

V

V

V

V

V

V

V

Module 1

Heating

Module 2

Heating and Cooling

Module 3

Cooling

Source

Load Cooling

Load Heating

*Simplified single line water circuit shown; V=motorized isolation and control valve

Index any module for heating or cooling at ANY time

Heat Pump Model

• Lower compression ratios due to operation at neutral source temperatures

• Provides hot water, as high as 135

o

F, utilizing R-410A refrigerant and 165

o

F utilizing R-134a refrigerant

• Built in modulating head pressure control

• No mixing of source and load liquids (water/glycol) solutions

Figure shows a bank of three modules:

Module 1 in Cooling

Module 2 in Standby

Module 3 in Heating

V

V

V

V

V

V

V

V

V

Module 1

Cooling

Module 2

Standby

Module 3

Heating

Source

Load Cooling

Load Heating

MODEL

UCH

VOLTAGE

A

UNIT

WIDTH

(in.)

B

HEIGHT WITHOUT

SOUND ENCLOSURE

(in.)

C

HEIGHT WITH

SOUND ENCLOSURE

(in.)

D

HEADER

WIDTH

(in.)

E

UNIT

DEPTH

(in.)

UNIT

WEIGHT

1

(lb.)

OPERATING

WEIGHT

2

(lb.)

HEADER

CONNECTION

SIZE

3

(in.)

030

208/230/460/575/3/60

34

76 7/8

78

34 1/4

55 1/2

1530

1850

6

050

208/230/460/575/3/60

34

76 7/8

78

34 1/4

55 1/2

2150

2460

6

070

208/230/460/575/3/60

34

76 7/8

78

34 1/4

55 1/2

2400

2710

6

085

208/230/460/575/3/60

34

83 7/8

84 7/8

34 1/4

67

2850

3350

8

Notes:

1. Unit shipping weight includes refrigerant charge, compressor oil and packaging.

2. Operational weight includes refrigerant charge, compressor oil and water.

3. The model UCH085 cannot be directly coupled with model UCH030, 050 or 070 due to differences in header and frame size.

*Simplified single line water circuit shown; V=motorized isolation and control valve

on

DEMAND

®

SIMULTANEOUS HEATING AND COOLING

on

DEMAND

®

SIMULTANEOUS HEATING AND COOLING

on

DEMAND

®

SIMULTANEOUS HEATING AND COOLING

on

DEMAND

®

SIMULTANEOUS HEATING AND COOLING

on

DEMAND

®

SIMULTANEOUS HEATING AND COOLING

on

DEMAND

®

SIMULTANEOUS HEATING AND COOLING