J&M TB-8000H-42 User Manual

Page 18

Pg. 18

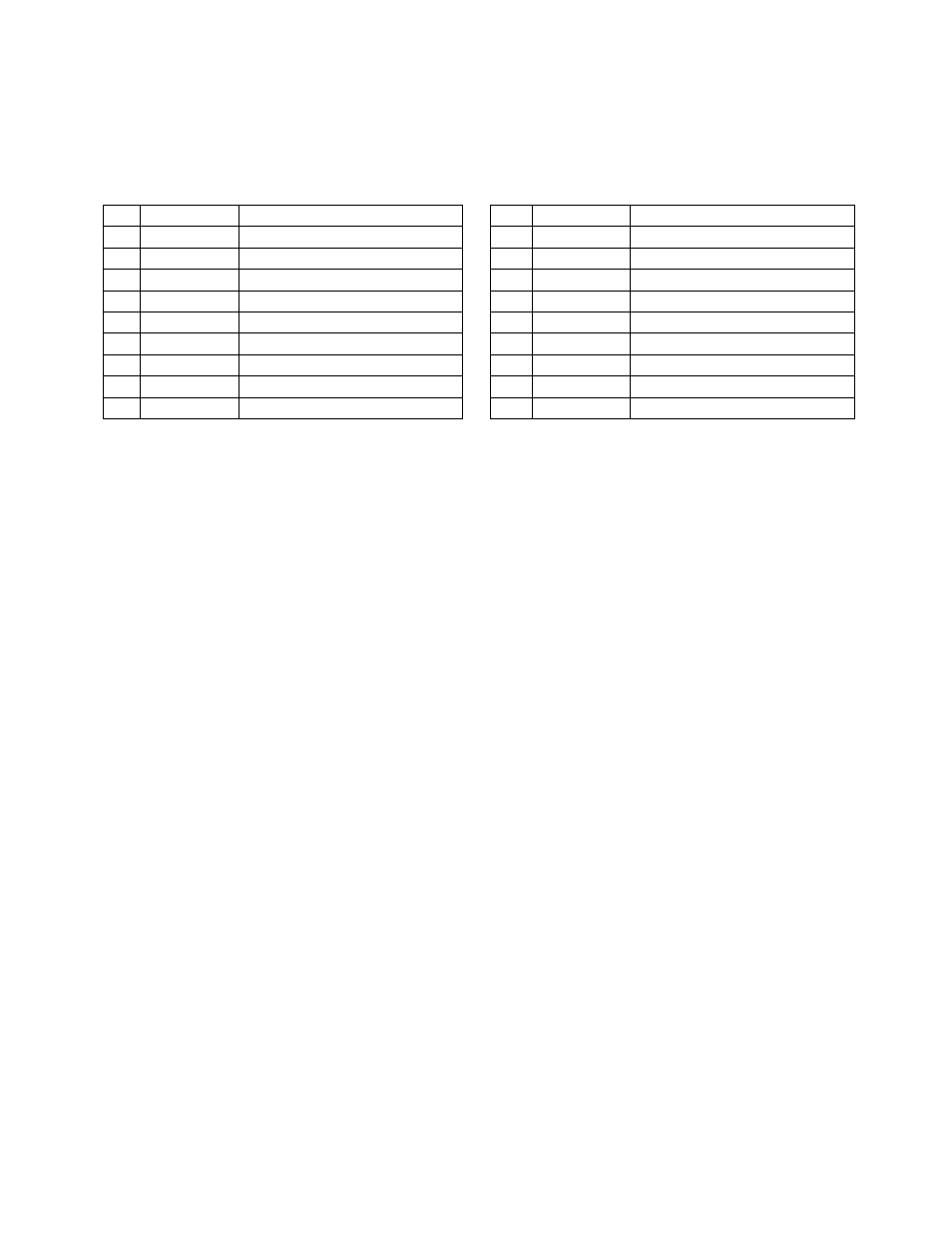

PARTS LIST

Light Kit and Wiring Diagram

Parts List (continued)

INITIAL OPERATION / MAINTENANCE

BE CERTAIN THAT ALL POWER IS SHUT OFF BEFORE SERVICING THE HEADER TRANSPORT

Before the header transport is put into service:

Has the Slow-Moving Vehicle Emblem been properly positioned at the rear of the header

transport?

Have all danger, warning, caution and important signs on the equipment been read and

understood? If employees or others use or are near this equipment, make sure that they also

have read and understood all danger, warning, caution and important signs on the equipment and

have also read the operator’s manual.

Are all braces, bolts, nuts, lug bolts and lug nuts properly fastened?

Has the header transport been properly fastened to the towing unit? Use a good quality hitch pin

with clip and safety chains.

Are the rear amber extremity lights properly positioned? Extend lights within 16” of the left and

right extremities of the header.

SAFETY CHAIN USER INSTRUCTIONS

a) Secure the safety chain by looping it around the tongue support located on the underside of the

Ball Hitch Tongue

and connect to the towing machine’s attaching bar.

b) Do Not allow more slack than necessary for articulation.

c) Do Not use any intermediate support as the attaching point.

d) Store the safety chain by securing it around the tongue.

e) Replace the safety chain if one or more links or end fittings are broken, stretched or otherwise

damaged or deformed.

OPERATING INSTRUCTIONS/MAINTENANCE

Adjust the brackets on the header transport to best fit your make and model header. When

mounting the header, NEVER position yourself under or near the header. Securely fasten the

header to the header transport.

Do not exceed the load and size limits of the unit.

Keep the tires properly inflated. Both under inflation and over inflation can greatly reduce tire life.

Inspect bracing and welds periodically and repair immediately if needed. Failure to repair could

cause extensive damage and greatly reduce the life of the unit.

Repack the bearings in the hub assembly once a year or as needed. Use a good quality bearing

lubricant such as Bearing Gard MK1 or equivalent.

Grease the ball using the zerk on the front gooseneck assembly every 8 hours or as needed.

Be sure to check the hub nuts often and keep them properly tightened.

#

Part #

Description

#

Part #

Description

17

-----

--------------------------------

26

14LN

1/4” Lock Nut

18

EB-1S

Extension Bracket, short

27

STS-1

Self Tapping Screw

19

AIS-2

Angle Iron Support (each)

28

LPMB-1

License Plate Mounting Bracket

20

127-HB

1/2” x 7” Hex Bolt

29

RD-SR1

Silver/Red Reflective Decal

21

12LN

1/2” Lock Nut

30

GR-134

Grommet

22

UBWC-2

Upper Bar Wire Cover (2 pcs)

31

WC-1

Wire Clip

23

WHB-1

Wire Harness Storage Bracket

24

RCW-1

Rubber Cap for Storage Bracket

25

141-B

1/4” x 1” Bolt