J&M GC-31T Manual User Manual

Page 37

35

L

UBrIcatIon

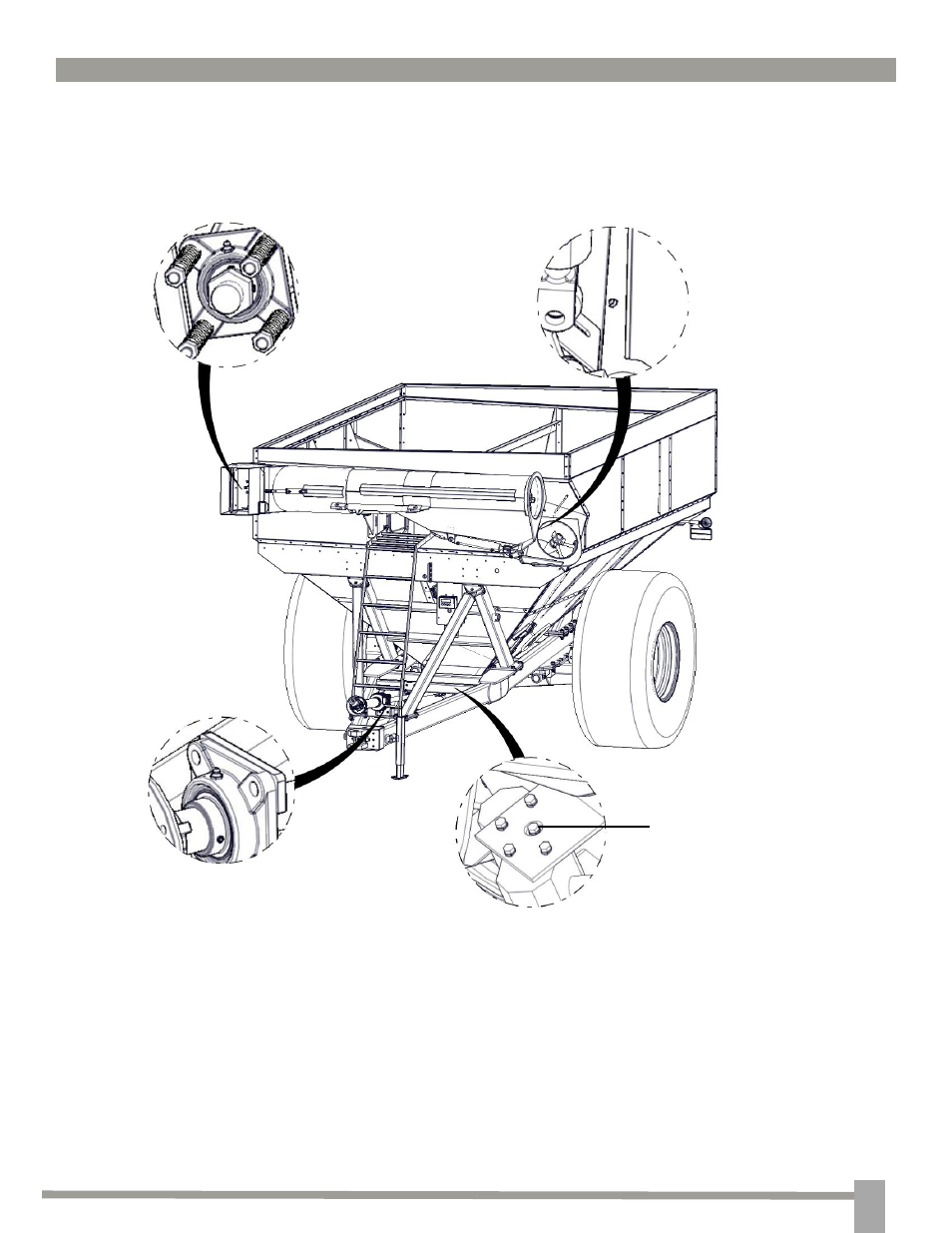

GEARBOX: Gearbox lubricant has been added to the gearbox

during final assembly. Recheck the lubricant level before

initial operation of the grain cart, then periodically according

to use. An inspection plug is located in the center of the top

of the gearbox mount plate. To check the fluid level, remove

the vented inspection plug and drain plug at the bottom of the

gearbox. Drain the lubricant. Return the drain plug and refill

the gearbox with 24 ounces (0,71 liters) of gearbox lubricant.

The gearbox is properly filled when half full of lubricant.

DO NOT OVERFILL. Use EP 80-90 gearbox lubricant or

equivalent.

SPRING LOADED UPPER AUGER BEARING: Service

the grease fitting on the upper auger bearing (located at

the top end of the upper auger assembly) after every 8

hours of use. Lubricate the springs and retaining bolts on

the bearing before prolonged storage of the grain cart.

AUGER FOLDING MECHANISM: One grease fitting is located

on the pivot pin of the folding auger. This fitting should be

serviced after every 8 hours of use. Service the grease fitting

on the hanger bushing assembly (top end of the lower auger

assembly) after every 8 hours of use or as needed.

PTO & DRIVELINE: The grease fittings

on the PTO should be serviced after every

8 hours of use. Service the grease fittings

on each of the drive bearings and also the

universal joint after every 8 hours of use.

HITCH: There is a grease fitting located on

the pivot shaft of the swivel hitch for grain

carts equipped without an electronic weigh

system (scales).

Inspection Plug