5 tightening the pem nut, 6 rebuilding the cylinder, Ightening the – Castle AT-8 OB User Manual

Page 26: Ebuilding the, Ylinder

6.5 Tightening the PEM Nut

Note: This procedure requires two people to remove the arm assembly from the table.

The cylinder lever is held against the body of the cylinder with a PEM nut. If you notice that the

cylinder lever has come loose or that your clamp cylinder does not hold pressure the PEM nut

may have come loose. This nut can be tightened by first removing the cylinder and then

tightening up the nut.

1. Turn off the air and remove the airline for the cylinder with the loose lever. The line is

connected to the cylinder by a push-in fitting. Simply push the outer ring in as you pull

the airline.

2. Remove the arm from the upper bracket by removing the bolts in the bracket. This can

be done with the arm on the machine, but will require a second person to hold the

bottom bracket firmly against the table.

3. Loosen the tension screw on the side of the cylinder

channel.

4. Take out the two Wear Strip Attachment screws on each

side of the cylinder channel and pull the clamp cylinder

assembly off the arm.

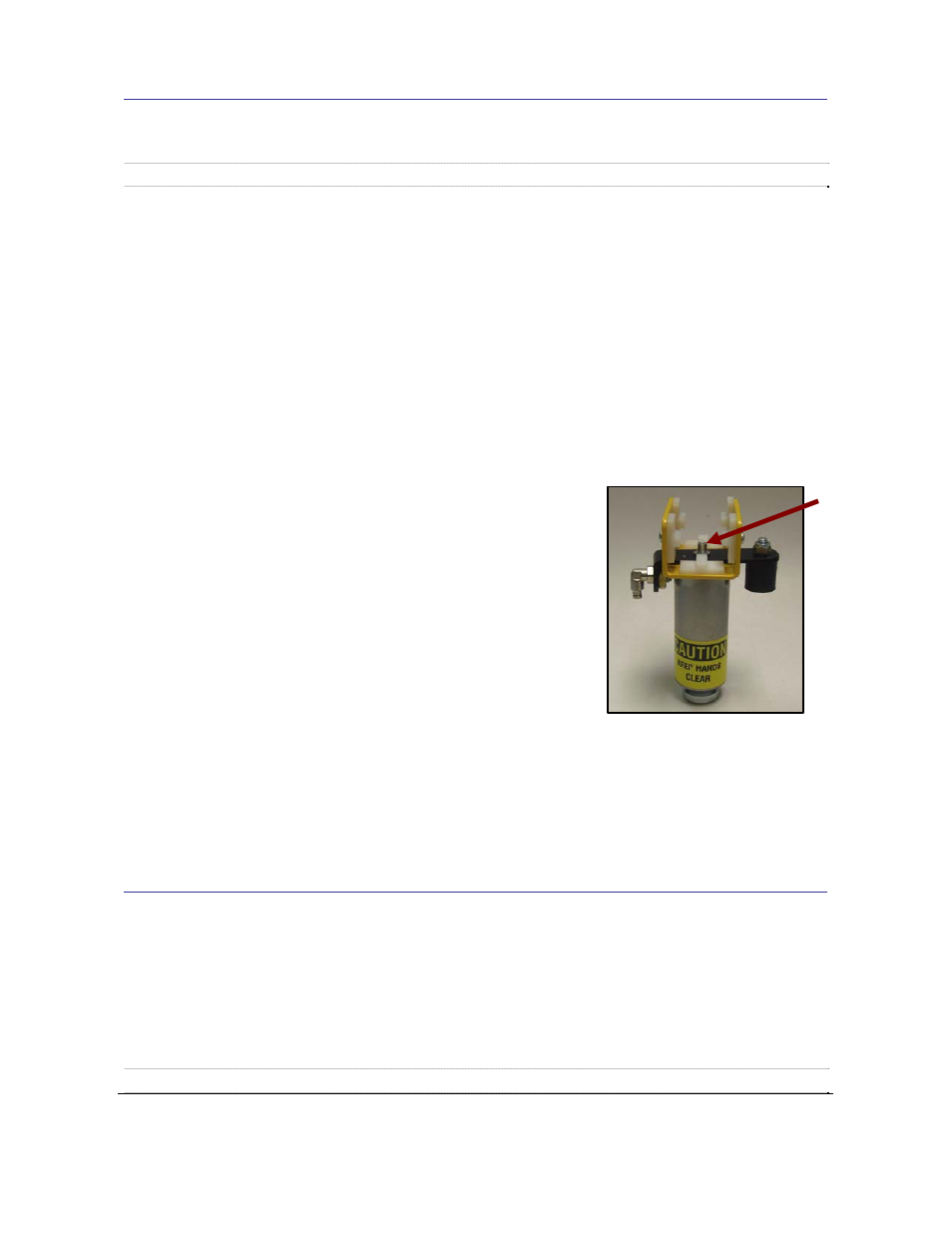

5. Tighten the PEM nut at the top of the cylinder using a

5/16 socket and check the action of the lever. It should

be relatively difficult to move when it is off the arm.

6. Slide the cylinder(s) back onto arm.

7. Replace the cylinder assembly including the cylinder channel back onto the arm.

Replace the wear strip attachment screws and tighten.

8. Tighten the bracket tension screw until the desired slight resistance is achieved.

6.6 Rebuilding the Cylinder

The cylinders have several rings and gaskets that help maintain pressure within the cylinder.

Over time these seals can become worn or damaged and may need to be replaced. Refer to the

parts clamp cylinder detail

and parts list in Appendix A & B for specific part identification.

Note: This procedure requires two people.

CASTLE, INC

AT‐8 OB OWNERS MANUAL V2.1

Page 26 of 32