Microphone, 5 .application – BeStar BCMMEMS001A-42 LF User Manual

Page 5

C

Drawn

A

Rev.

6

Date

A

B

5

Note

4

Approved by:

Date:

Drawn by:

Checked by:

3

2

王焕焕

T

h

is

p

ri

n

t

a

n

d

i

n

fo

rm

a

tio

n

t

he

re

i

n

a

re

p

ro

p

ri

e

ta

ry

t

o

B

e

s

ta

r

E

le

c

tr

o

n

ics

I

ndu

s

tr

y

C

o

.,

L

td.

a

nd

s

h

a

ll

no

t

b

e

u

s

ed

i

n

w

h

o

le

o

r

in

pa

rt

w

ith

ou

t

it

s

w

ri

tt

en

c

on

tent

D

E

F

G

H

6

5

4

3

2

C

A

Page:5 of 8

1

B

D

E

F

G

1

H

10.04.27

DRG NO:

Microphone

BS/TEM01.159A

10.04.27

王焕焕

徐 波

张秀琴

Acoustics & Sensor

4.11.PC Board Solder Adhesion :

Each test PC board shall contain only one part .Place PC Board for testing upside

down on two supports spaced 90mm apart centering the part to within

±1mm of

the span .Orient this part such that the longest dimension is perpendicula between

the two supports. Next using a force gauge ,also centering to within

±1mm of the

span's center ,slowly apply a downward vertical force and push with increasing

force until the part's terminations separate from the PC board. Record at which

deflection point mechanical failure occurs. Parts shall withstand a minimum

deflection as described below .Repeat for each test sample. Identify precisel y

where termination stress failure(s) occur and include at least one picture

.

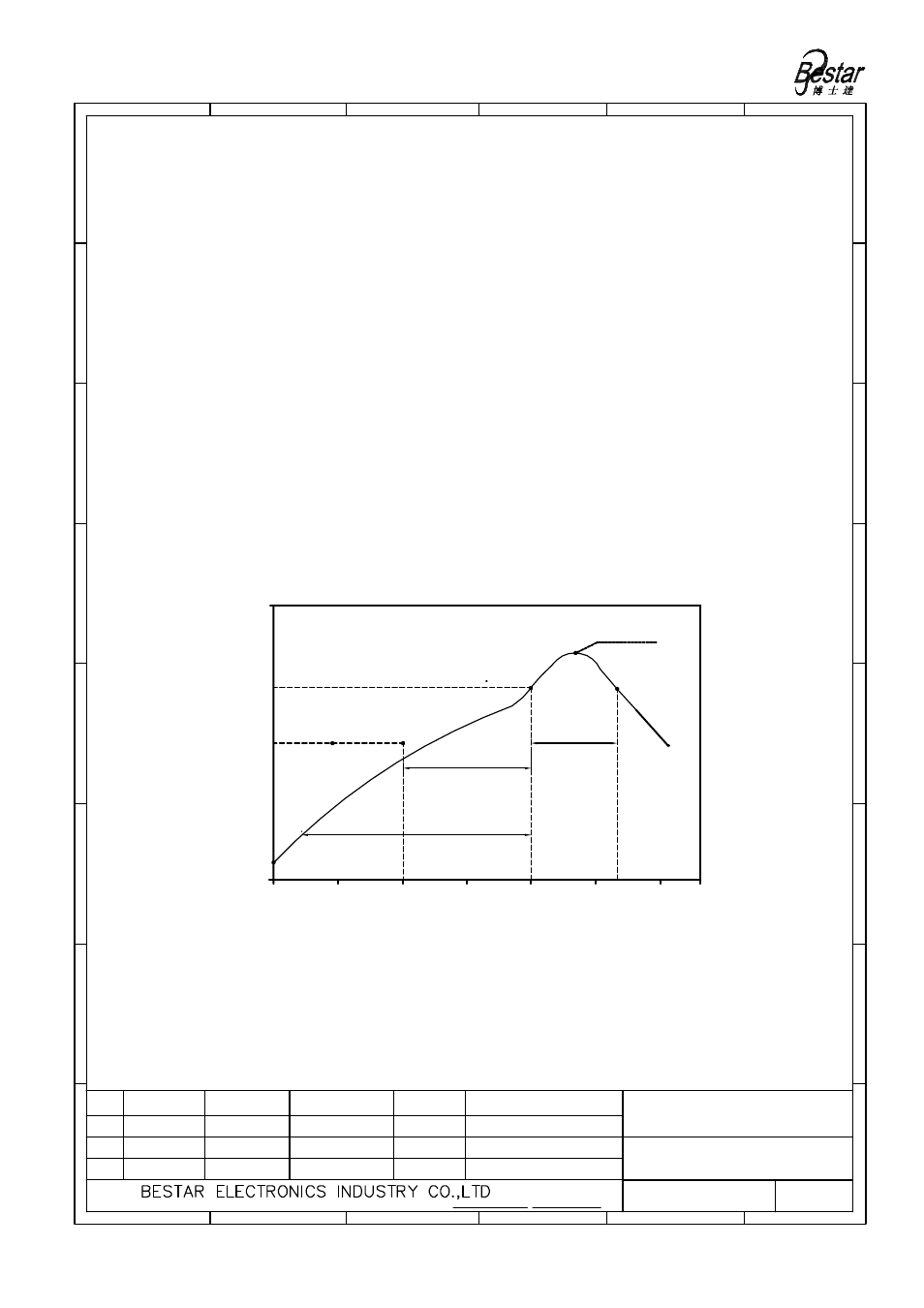

5 .Application:

5.1 Storage temperature range : -40 ℃ ~ +100℃

Operation temperature range : -40 ℃ ~ +100℃

5.2 Recommend Re-flow Prifile

50

150

100

200

T

e

m

p

e

ra

tu

re

[

℃

]

45

0

0

90

min.2.5

℃/sec

time [sec]

180

135

225

270

250

300

Peak Temp

245 ~ 265 ℃

300

Pre Heating Zone

Reflow Zone

Time above 217

Soaking Zone

(120 sec max)

Typical 60 - 90 sec

(90 sec max)

Typical 60 - 90 sec

(120 - 240 sec max)

BCMMEMS001A-42 LF

BCMMEMS001A-42 LF