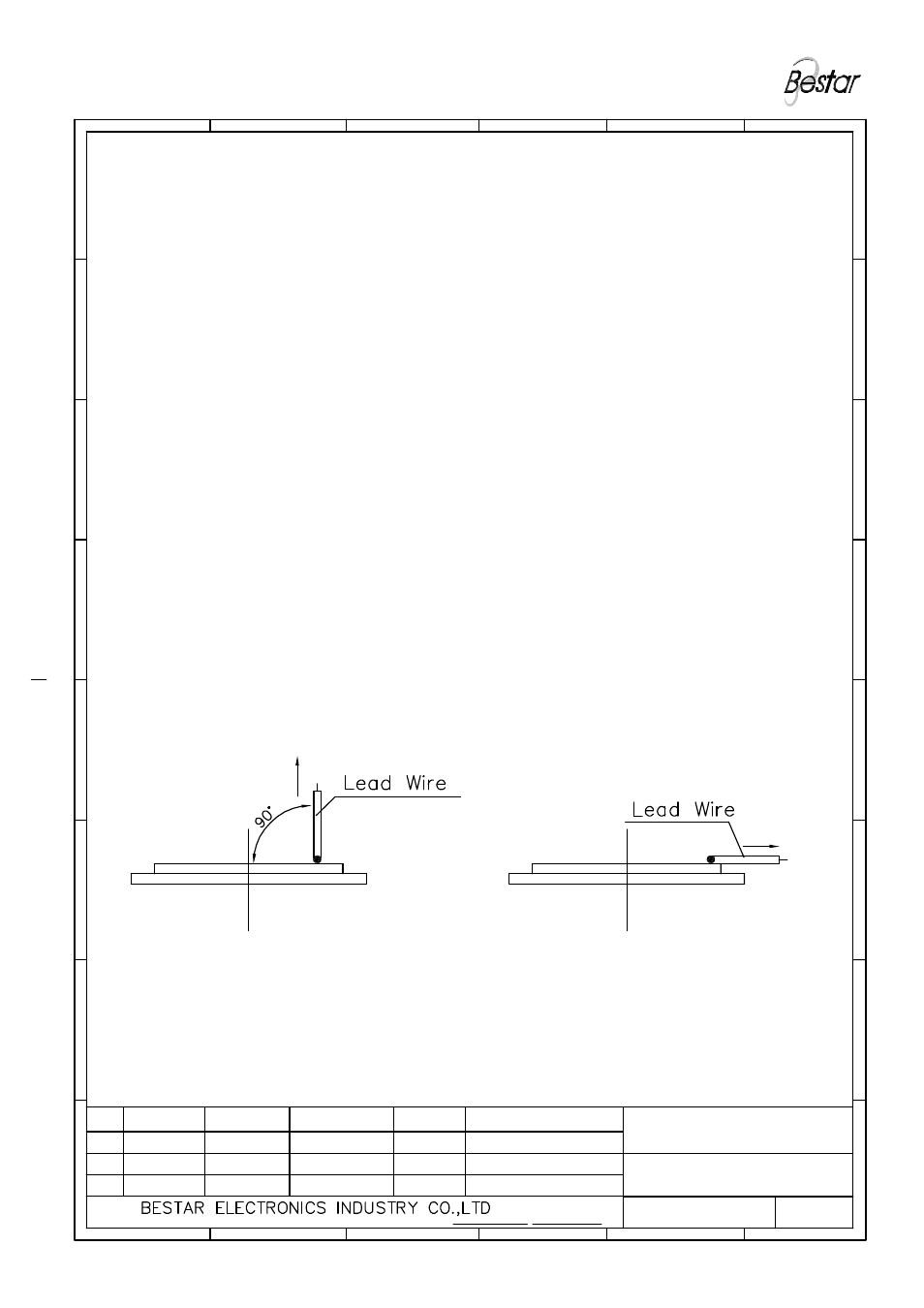

Characteristics, Fig.2 direction of lead wire, Fig.1 direction of lead wire – BeStar FT-32G-3.2A12-03 User Manual

Page 3: Piezo element

T

h

is

p

ri

n

t

a

n

d

i

n

fo

rm

a

tio

n

t

he

re

i

n

a

re

p

ro

p

ri

e

ta

ry

t

o

B

e

s

ta

r

E

le

c

tr

o

n

ics

I

ndu

s

tr

y

C

o

.,

L

td.

a

nd

s

h

a

ll

no

t

b

e

u

s

ed

i

n

w

h

o

le

o

r

in

pa

rt

w

ith

ou

t

it

s

w

ri

tt

en

c

on

tent

DRG NO: BS/TEY01.333A

A

Rev.

A

5

6

4

3

Drawn

Date

Note

Drawn by:

汤浩君

Approved by:

Checked by:

赵

峥

Date:

1

Page:3 of 6

2

Piezo Element

A

Fig.2 Direction of Lead Wire

B

Fig.1 Direction of Lead Wire

C

D

B

C

D

3.1 Solderability

280

±10 Temperaure of Merited Solder,1±0.5sec Duration of Dipping.

℃

3.2 Lead pull off test

a) Wire to be soldered on ceramic at the edge. It should withstand minimum20N

force applied in 180

° .The wire should not come out before this .The ceramic can be either

glued on a surface of can be held in hand.(Fig.2)

b) Wire to be soldered on ceramic at the edage&should be pulled up at 90

° The element

should be hold on bottom and wire should be pulled up .It should withstand at least for2N

force(Fig.1)

3.3Bend Test

The element should be bend on to a pipe of 31

±2mm diameter.The bend should be in only

one direction. The length of pipe should be at least 1.5 times the diameter of the stainless

steel.

E

F

G

E

F

G

3.Characteristics:

H

5

6

4

3

H

1

2

10/03/12

FT-32G-3.2A12-03

FT-32G-3.2A12-03

10/03/12

赵

峥

李红元

博 士 達