Reliability test, 9 recommended temp. profile for reflow oven, Bestar electronics industry co.,ltd – BeStar BSP1212-03H2.5B-01 LF User Manual

Page 4: Piezo sounder, 30 10s

Date:

Drawn by:

BESTAR ELECTRONICS INDUSTRY CO.,LTD

Checked by:

Approved by:

T

h

is

p

ri

n

t

and

i

n

fo

rm

a

ti

on

t

he

re

i

n

a

re

p

rop

ri

e

ta

ry

t

o

B

e

s

ta

r E

le

c

tr

on

ics

I

ndu

s

tr

y

C

o

.,

L

td

.

and

s

ha

ll

no

t

be

u

s

ed

i

n

w

ho

le

o

r

in

p

a

rt

w

it

hou

t

it

s

wr

itt

en

c

on

tent

4

5

6

Rev.

Date

A

Drawn

Note

B

C

D

E

F

G

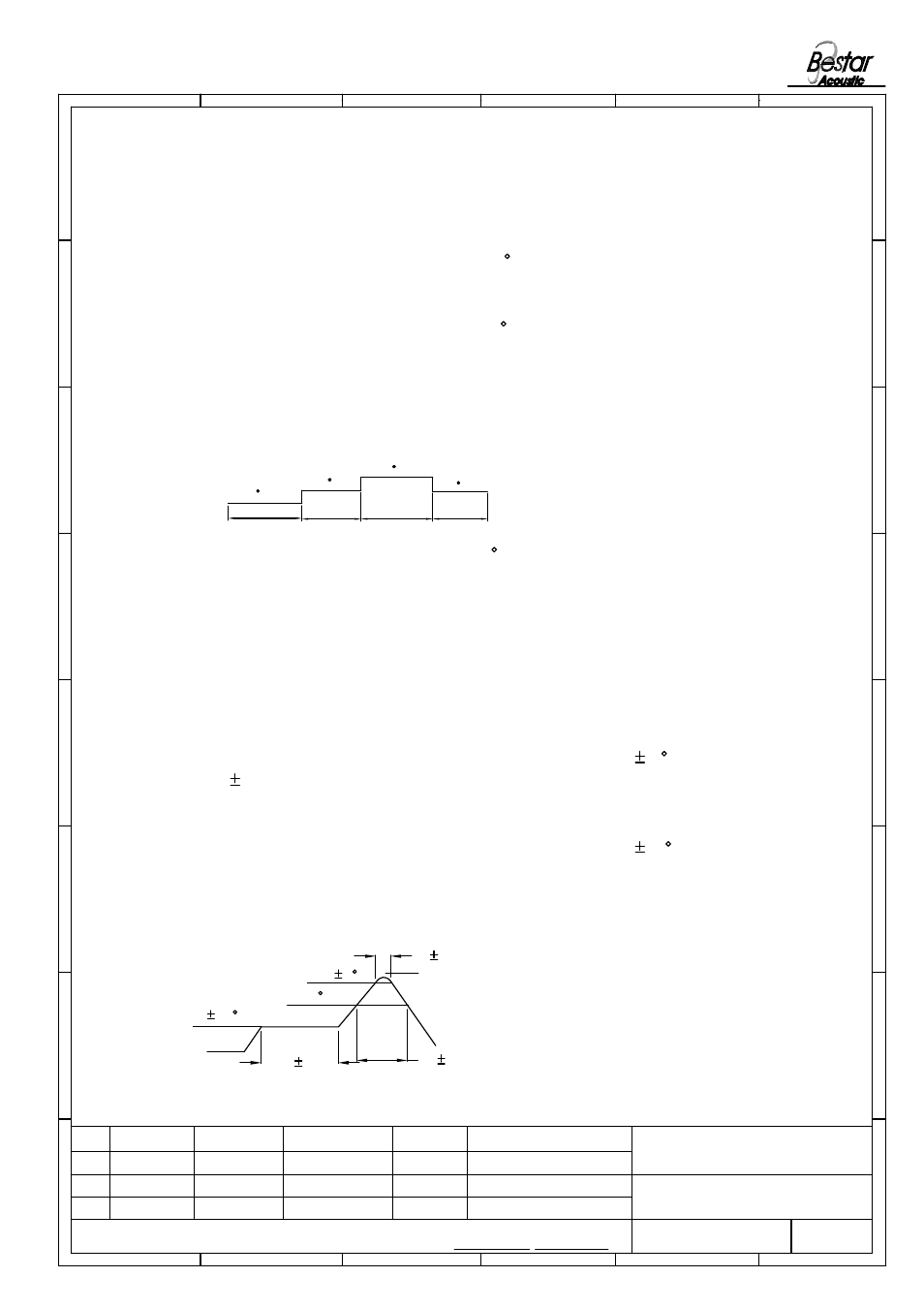

3. Reliability test

H

6

5

4

1

2

3

Piezo Sounder

Page:3 of 6

A

B

C

D

E

F

G

3

H

2

1

3.6 Drop test

Height 70cm

(to 10mm thickness woodenboard)

Direction 3

3.7 Solderability

The part lead pins shall be immersed in molten solder maintained at 255 5 C for

a period of 3 0.5 seconds.

After the test ,95% coverage with a continuous coating of bright solder

3.8 Solder Heat Resistance

The part lead pins shall be immersed in molten solder maintained at 255 10 C for

a period of 30seconds

After the test, the part shall meet the specification without any degradation in appearance and

performance

Notice: All specification must be satisfied in this condition.

SPL: allowable deviation 4dB of the initial value after testing

30min

3.1 high temperature test

Temperature +85 C

Duration 96hrs

3.2 low temperature test

Temperature -40 C

Duration 96hrs

3.3 life test in normal temperature

Power supply rated voltage

Duration 1000hrs

3.4 temperature cycle test

all these tests above should be measured after leaving normal temperature for 2hrs.

Cycles 5

3.5 Humidity test

Temperature +40 C

Relative Humidity 93%

Duration 96hrs

30min

+20 C

15min

-20 C

+70 C

15min

+20 C

90 3s

10 1s

245 5 C

260max

30 10s

217 C

3.9 Recommended Temp. Profile for Reflow Oven

150 10 C

A

BSP1212-03H2.5B-01 LF

08/04/03

赵 峥

08/04/03

赵 峥

李红元

张秀琴

BSP1212-03H2.5B-01 LF

DRG NO: BS/TEP01.580A