Notice, Piezo sounder, A赵 峥 – BeStar BSP1515-07H6.8 LF User Manual

Page 5

T

h

is

p

ri

n

t

a

n

d

i

n

fo

rm

a

tio

n

t

he

re

i

n

a

re

p

ro

p

ri

e

ta

ry

t

o

B

e

s

ta

r

E

le

c

tr

o

n

ics

I

ndu

s

tr

y

C

o

.,

L

td.

a

nd

s

h

a

ll

no

t

b

e

u

s

ed

i

n

w

h

o

le

o

r

in

pa

rt

w

ith

ou

t

it

s

w

ri

tt

en

c

on

tent

B

6

A

4

5

3

C

2

1

A

B

C

D

E

F

G

H

6

4

5

3

D

E

F

G

1

2

5. Notice

Drawn by:

Approved by:

Checked by:

Date:

Page:05 of 06

DRG NO:BS/TEP01.625A

Piezo Sounder

李红元

Drawn

Rev.

Date

Note

邱 俊

10/03/23

赵 峥

李红元

邱 俊

10/03/23

BSP1515-07H6.8LF

赵 峥

BSP1515-07H6.8LF

A

赵 峥

5.1 Storage Condition

The products should be stored in the room ,where the temperature/humidity is

stable. And avoid such

places where there are large temperature changes. Please store the products at

the foll-

owing conditions:

Temperature: -10 to + 40

C Humidity: 15 to 85% R.H.

5.2 Expire Date on Storage

Expire date (Shelf life) of the products is six months after deliveried under the

conditions of a

sealed and an unopened package. Please use the products within six months

after deliveried.

If you store the products for a long time (more than six months), use carefully

because the

products may be degraded in the solderability and/or rusty.Please confirm

solderability and

characteristics for the products regularly.

5.3 Notice on Product Storage

(1) Please do not store the products in a chemical atmosphere (Acids, Alkali,

Bases, Organic

gas, Sulfides and so on), because the characteristics may be reduced at quality,

and/or be d-

egraded in the solderability due to the storage in a chemical atmosphere.

(2) Please use the products immediately after the package is opened, because the

character-

istics may be reduced at quality, and/or be degraded in the solderability due to

storage under

the poor condition.

(3) Please do not drop the products to avoid cracking of ceramic element.

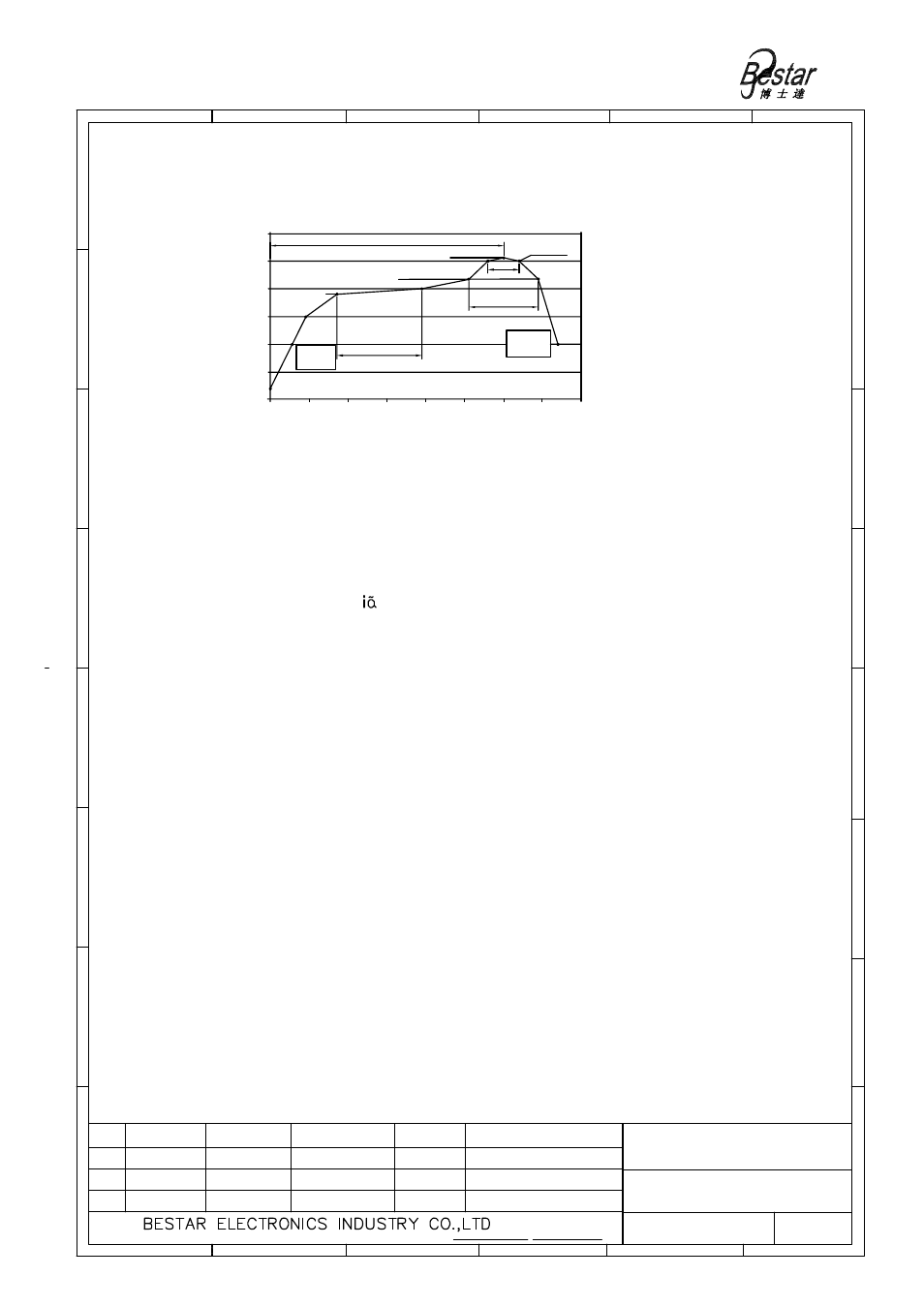

4.11 Recommended Temp. Profile for Reflow Oven

T

e

m

p

e

ra

tu

re

[

℃

]

min.110s

0

0

100

50

100

50

ramp up to

150℃

min.3k/s

250

time [s]

200

150

350

300

ramp down

from T(solid)

min.6k/s

min.300s

200

150

min.190℃

300

250

min.40s

T(solid)min.217

℃

max.90s

max.260℃

max.255℃

Temperature profile for a lead-free reflow process

400

10/03/23

Acoustics & Sensor