Elmo Rietschle V-KTA 80/5 User Manual

Page 13

13

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

|

Bauj./Nr. 09

S1 5,50 / 6,50

kW

Typ KTR 100 (01)

+ 0,60 / - 0,60 bar

2843970

100 / 120 m³/h

EN 60034

1460 / 1745 min

-1

1027630137

3~

Mot.

Set up and operation

6

1

7

8

9

10

3

4

5

2

4.2 Description

The V-KTA range has a connecting thread on the pressure side and on the suction side. The aspirated air

is cleaned by an inbuilt fi ne micro fi lter. The carbon dust caused by the scoring of the discs can also be

separated by an integral fi lter if necessary. A fan between the compressor housing and the motor provides

intensive air cooling. The compressor housing is located in a sound cover. The compressed air is cooled by

a cooling segment.

The machines are driven by standard fl anged three-phase motors using a coupling.

Pressure and vacuum can be adjusted to the required levels, however, they are limited to a maximum point.

Versions (01) to (30) have cooling exits from two sides whilst versions (31) to (60) have cooling exits on one

side only.

4.3

Areas of application

These dry running rotary vane pressure vacuum pumps models V-KTA 60/1 to V-KTA 140/3 and V-KTA 80/5

are suitable for creating pressure and vacuum at the same time. Constant operation is permissible.

All models have nominal capacities of 60, 80, 100 and 140 m

3

/hr operating at 50 cycles. The pressure and

vacuum limits (bar) are indicated on the data plate (Fig. 2/N). The tables showing capacity against pressure

and vacuum can be seen in data sheets D 452 and D 453.

These dry running machines are suitable for conveying air with a relative humidity of 30 - 90%.

If the unit is switched on more frequently (at regular intervals of about 12 times (V-KTA 60 / 80)

resp. 10 times (V-KTA 100 / 140) an hour) or at higher ambient temperatures and intake tempera-

tures, the excess temperature limit of the motor winding and the bearings may be exceeded.

Please contact the manufacturer should the unit be used under such conditions

If it is installed in the open air the unit must be protected from environmental infl uences, (e.g. by a

protective roof).

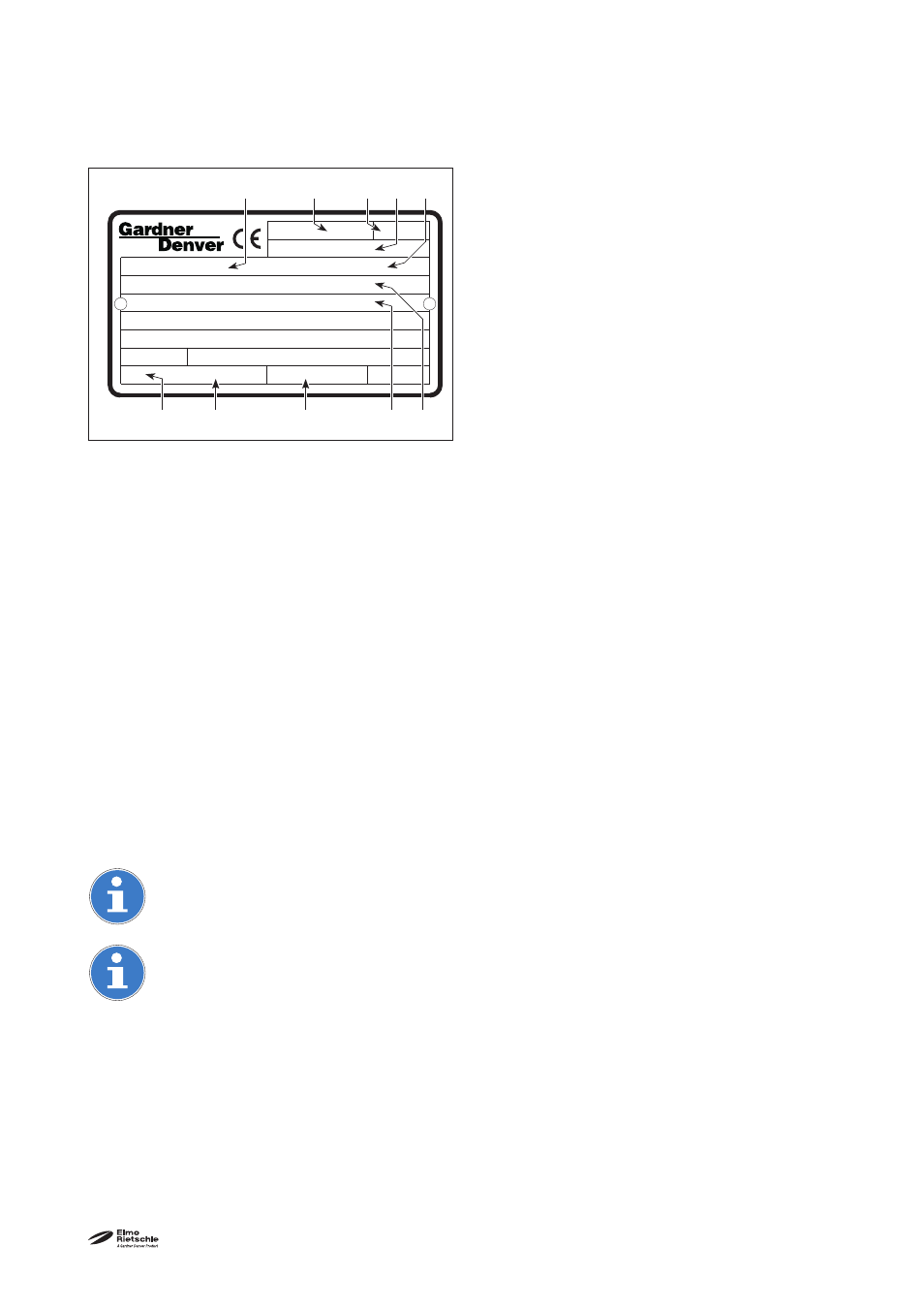

4.1.1 Data plate

Fig. 3 Data plate (example)

1

Type/ Size (mechanical version)

2

Year of construction

3 Motor

design

4 Serial

number

5 Item

no

6

Overpressure / Vacuum

7

Pumping capacity 50 Hz / 60 Hz

8 Speed

50

Hz / 60

Hz

9

Motor output 50 Hz / 60 Hz

10 Operating

mode