Elmo Rietschle V-VTA 60/80/100/140 User Manual

Page 20

20

|

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

Maintenance and repair

M

L

L

G

w

1

w

1

s

s

The bearings must be greased at the 2 greasing

points (Fig. 4/L) with 6 g per point, after the follow-

ing recommended operating hours or at the latest

one year operation:

50 Hz: V-VTA 60 - 100

➝ 10.000 h and V-VTA 140 ➝

6.000 h

60 Hz: V-VTA 60 / 80

➝ 10.000 h, V-VTA 100 ➝

8.000 h and V-VTA 140

➝ 4.000 h

NOTICE

These greasing instructions are valid for operation

at 20°C ambient temperature. At 40°C these should

be reduced by 50 %.

To lubricate the inlet grating (Fig. 4/G) must be un-

screwed.

We recommend the following brands of grease:

KlüberPetamoGY193 or other equivalent greases

(see also grease recommendation plate (Fig. 4/M)).

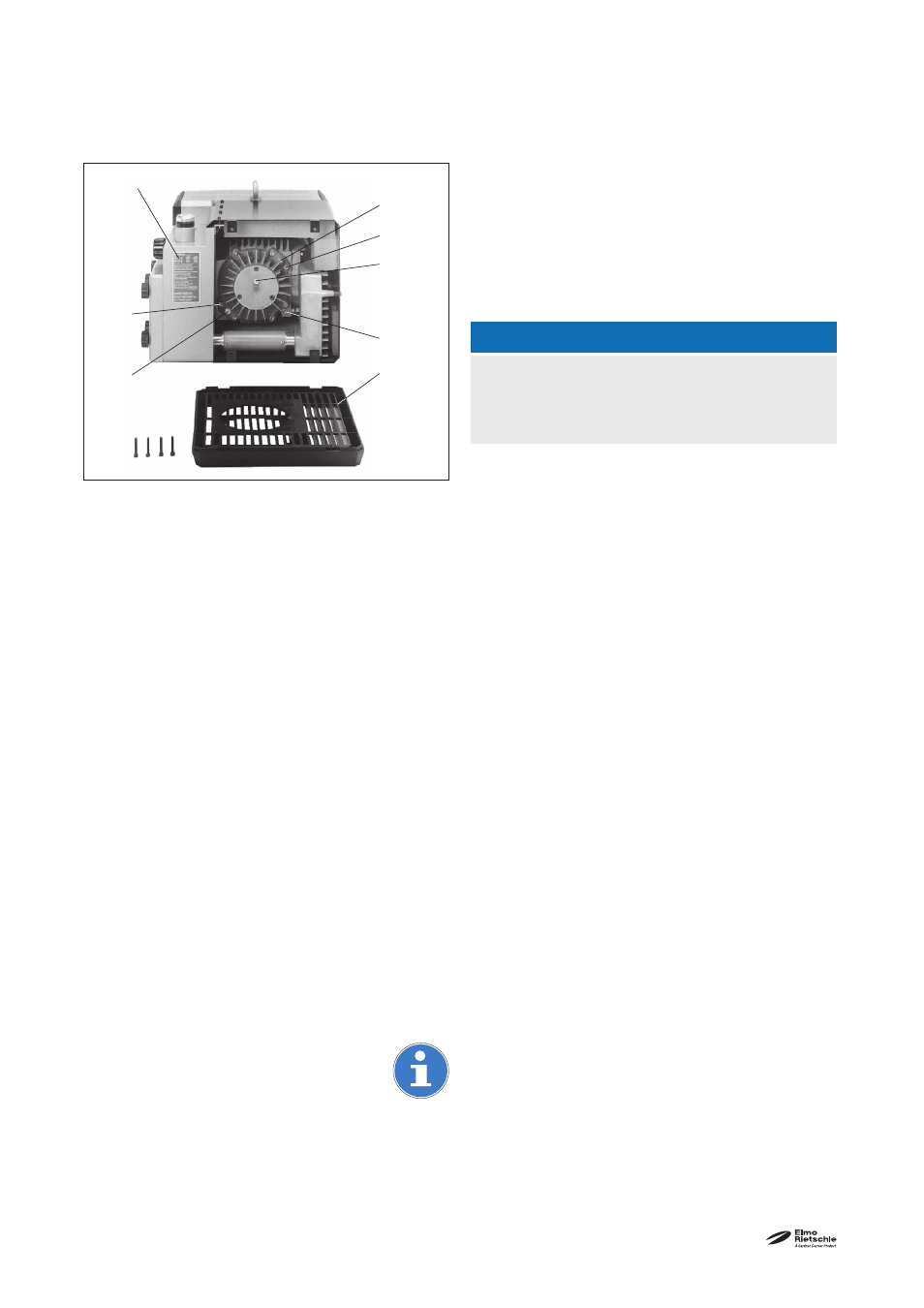

Fig. 4 Lubrication/ Blades

G

Inlet grating

L Grease

nipple

M

Grease recommendation plate

s

Screws

w

1

Slotted nut

7.2.1 Lubrication

7.2.2 Blades

Blade check:

V-VTA models have 4 carbon blades that gradually

wear out during operation.

First check after 4,000 operating hours and then

every 1,000 operationg hours or, depending on the

height (Fig. 6/X) earlier.

Remove inlet grating (Fig. 4/G). To remove the end

cover (Fig. 5/b) from the housing, the bolt (Fig. 5/a)

located in the centre of the bearing cover (Fig. 5/c)

should be removed. To achieve this one of the fi x-

ing bolts (Fig. 5/s) from the housing cover should be

screwed into the thread in the centre of the bearing

cover. Remove the blades (Fig. 6/d) to be checked.

All blades on the machine must have a minimum

height (Fig. 6/X) of more than 38 mm.

The blades must only be changed as a set.