Elmo Rietschle C-VLR 301 User Manual

Page 26

26

|

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

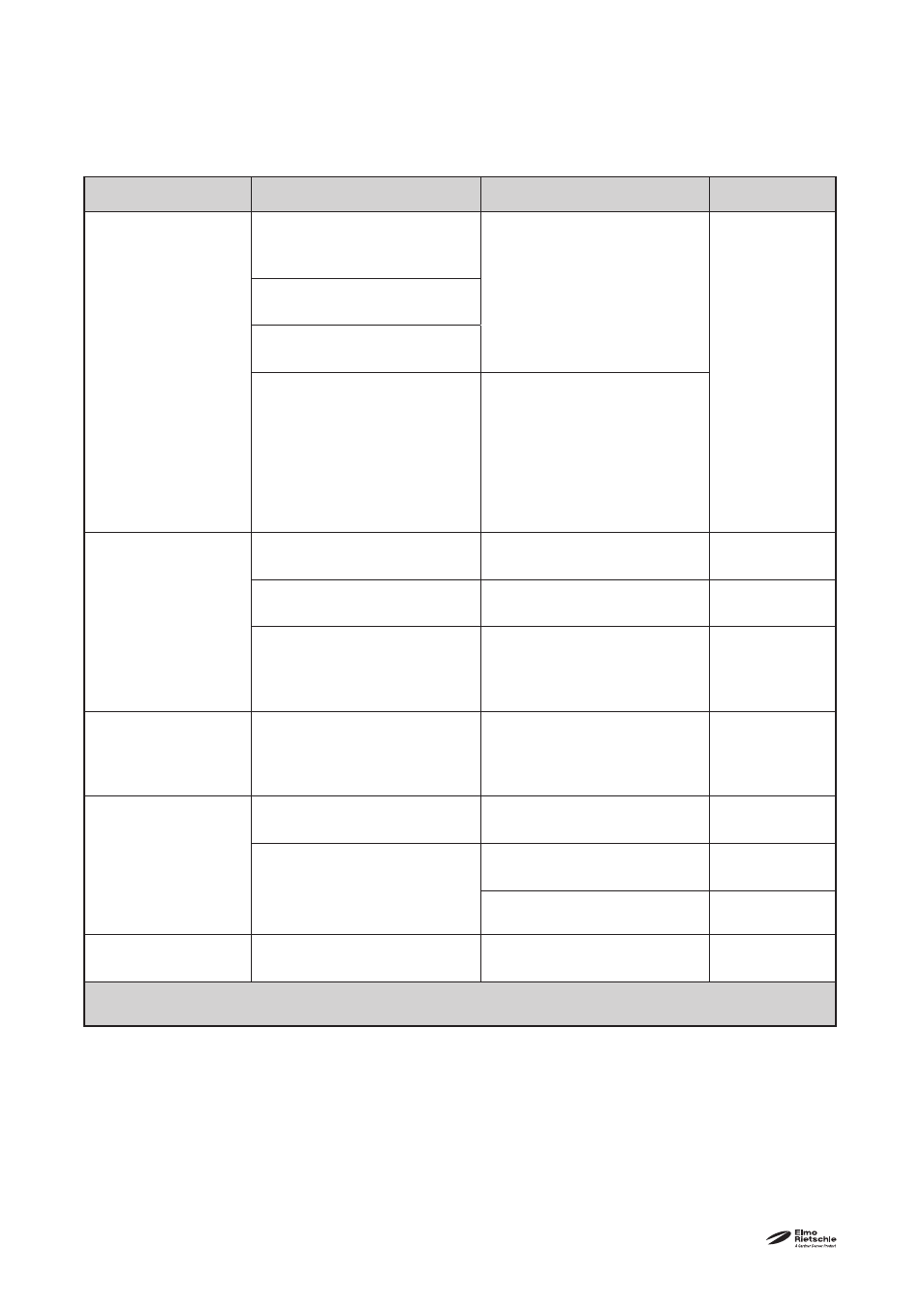

Malfunctions: Causes and elimination

Fault

Cause

Troubleshooting

Important

Machine is switched

off by the motor pro-

tection switch

Mains voltage/ Frequency

does not correspond with the

motor data

Check by qualifi ed electrician

Section 5.5

Connection to motor terminal

board is not correct

Motor protection switch is not

set correctly

Motor protection switch is

triggered too quickly

Use a motor protection switch

with an overload-dependent

delayed switch off that takes

into consideration the short

term excess current at start

up (version with short circuit

and overload trigger as per

VDE 0660 Part 2 orIEC 947-4)

Pumping capacity is

insuffi cient

The mesh fi lter is dirty

Clean or replace the fi lter

Section 7.2.2

Section 7.4

The suction pipe is too long or

too narrow

Check the hose or the pipe

Section 5.3

Machine or system leaking

Check the pipework and

screw connections for leaks

and to ensure that they are

fi rmly seated.

Section 7.2

Final pressure (max.

vacuum) is not

reached

Machine or system leaking

Check the pipework and

screw connections for leaks

and to ensure that they are

fi rmly seated.

Section 7.2

Machine gets too hot

Ambient or intake temperature

is too high

Ensure it is being used prop-

erly

Section 2.3

Cooling air supply is ob-

structed

Check environmental condi-

tions

Section 5.1

Clean ventilation slots

Section 7.2

The machine makes

an abnormal noise

Deposits on the rotary piston

Clean the working space and

the rotary piston

Elmo Rietschle

Service

Please contact Elmo Rietschle Service for other malfunctions or those that cannot be eliminated.

8

Malfunctions: Causes and elimination