Figure d, Figure c, Figure a – Liberty Pumps JB120/230 User Manual

Page 2: Figure b

22650 County Highway 6 P.O. Box 1708 Detroit Lakes, Minnesota 56502 USA

1-888-DIAL-SJE (1-888-342-5753) Phone: 218-847-1317 Fax: 218-847-4617

E-mail: [email protected]

Instl. Instr. PN 1011983G

©SJE-Rhombus Printed in USA 10/07

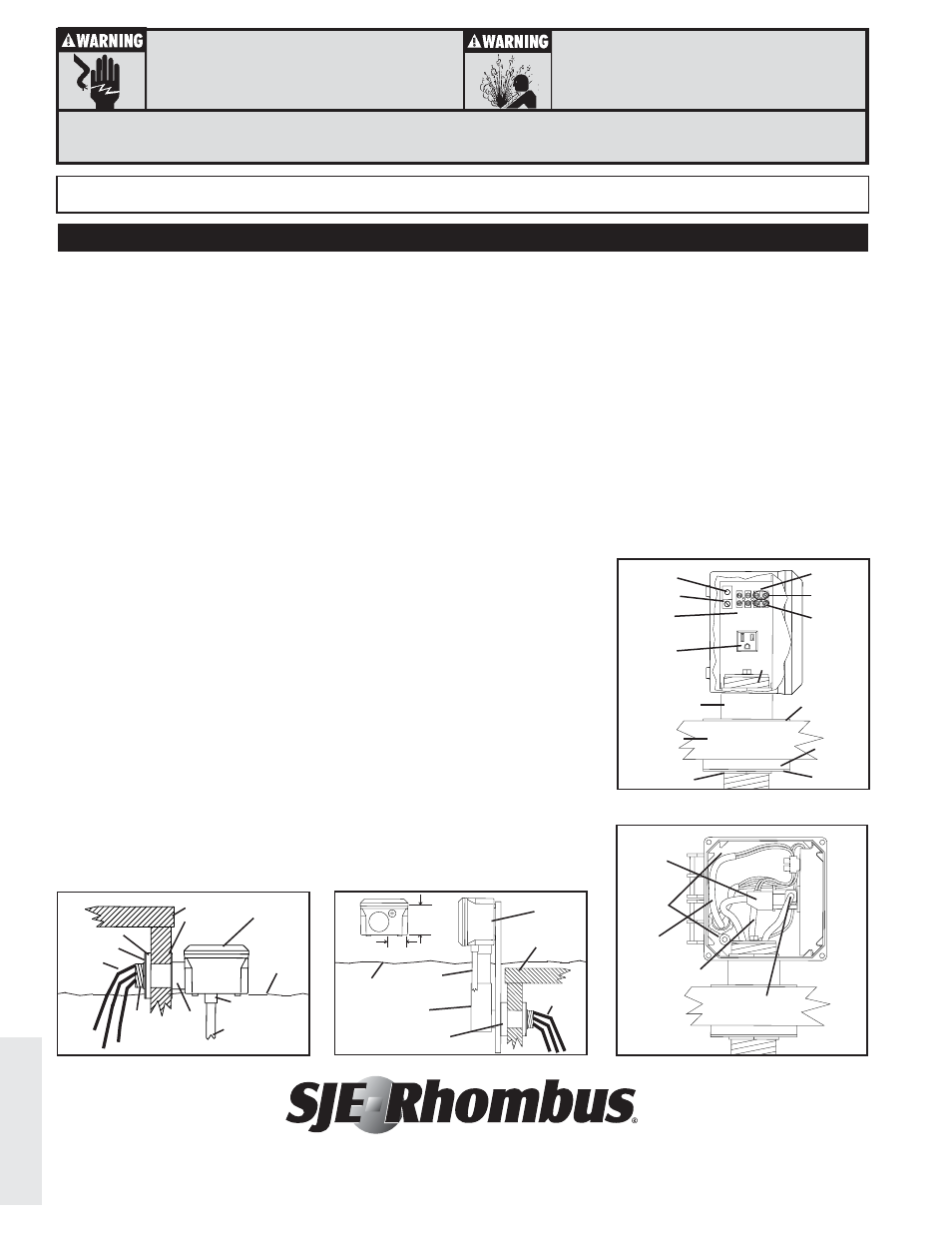

1. Determine where the junction box will

be mounted on the riser. Mount the

junction box so the base of the en-

closure will be at grade once back-

filled as shown in Figure A.

NOTE: Bottom mounting to the 3/4”

terminal adapter may be preferred

in some instances as shown in

Figure B.

2. Access the riser by providing a 2 3/8”

access hole through the riser.

3. Place the 6” threaded conduit into the

terminal adapter that is already

installed in the junction box. Slip one

PVC washer over the conduit and

slide the conduit through the riser

wall as shown in Figure C.

4. After installation through the riser, slip

the 1/2” gasket and the second PVC

washer over the conduit. Determine if

the threads provided will be adequate

to tighten the assembly to the riser. If

threading is not adequate, remove the

assembly and shorten the conduit

until threading is adequate as shown

in Figure C. NOTE: The 1/2” gasket

should compress approximately

1/4” when lock nut is tightened.

5. Repeat steps 3 and 4 until desired

length is achieved. With PVC solvent,

weld the conduit into the terminal

adapter.

6. Mount the 3/4” terminal adapter to the

bottom of the junction box with the O-

ring and lock nut provided. A 1 1/16”

hole should be provided for the

adapter.

7. Mount the assembly through the riser

as described in steps 3 and 4. Using

the 2” lock nut, compress the gasket

and riser to secure the junction box.

8. Remove the backplate assembly from

the enclosure. Bring the wiring for the

pump power and alarm junction through

the 3/4” terminal adapter. Connect the

conductors for the pump to the terminal

block; connect N (neutral) to position 1,

and L1 (line) to position 2. Connect L2

to position 1 for 230 VAC installations.

NOTE: Overload protection, branch

circuit protection and main

disconnect provided by others.

Connect the conductors for the alarm

circuit to positions 3 and 4 as shown in

Figures C and D. Place the backplate

assembly back into the enclosure.

NOTE: If an alarm system is not

used, plug the third open position

in the cord seal with the PVC plug

provided.

9. Pass the piggy-back plug, pump plug

and alarm float cables through the 2”

conduit.

10. With the three position cord seal, route

the three cables through the seal,

leaving approximately 8” of cable to

work with. Insert the cord seal into the

panel terminal adapter and tighten the

hex nut until adequate strain relief is

achieved.

11. Gather all ground wires, including

grounding conductor on the cord seal,

and washer. Route and secure to

ground terminal as shown in Figures C

and D.

INSTALL INSTRUCTIONS

INSTALLING THE JB PLUGGER JUNCTION BOX

For detailed specifications on this product, or for the complete line of SJE-Rhombus

®

panel, alarm, and switch products, visit our web-site at www.sjerhombus.com.

Figure D

pump plug

piggyback

plug

alarm float

switch

to alarm

panel

cable

coiling

detail

Figure C

ground

to alarm

panel

alarm

float

terminal

adapter

riser wall

lock nut

PVC

washer

PVC washer

cord

seal

pump

power

1 2 3 4

N L1

gasket

pump

float

switch

receptacle

grade

level

Figure A

riser

JB Plugger

conduit for electrical

(not included)

pump &

switch

cables

PVC washer

PVC washer

gasket

3/4” terminal

adapter

lock

nut

terminal

adapter

Figure B

conduit for

electrical

(not included)

LB conduit box

(not included)

spacer for lip

on riser lid

(not included)

grade

level

JB

Plugger

riser

pump &

switch cables

3”

2 1/16”

3/4” adapter location

12. Connect the conductors from the

alarm float switch to positions 3 and 4.

Coil remaining cable into the junction

box as shown in Figures C and D.

13. Seal the 3/4” terminal adapter with a

conduit sealing compound.

14. Plug the piggy-back plug and pump

plug into the receptacle as shown in

Figure D.

15. Secure the junction box cover using

the two preinstalled screws.

16. Turn on power.

17. Check the installation by manually

tipping the floats on the pump and then

the alarm float.

18. Test the unit periodically to insure

proper operation.

torque to

45 in-lbs

torque to

7 in-lbs

ELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing this

product. A qualified service person must install and

service this product according to applicable electrical

and plumbing codes.

EXPLOSION OR FIRE HAZARD

Do not use this product with flammable liquids.

Do not install in hazardous locations as defined by

National Electrical Code, ANSI/NFPA 70.

Failure to follow these precautions could result in serious injury or death. Replace product immediately if switch cable becomes damaged

or severed. Keep these instructions with warranty after installation. This product must be installed in accordance with National Electric Code,

ANSI/NFPA 70 so as to prevent moisture from entering or accumulating within boxes, conduit bodies, fittings, float housing, or cable.

112