Installation, Operation, Maintenance and troubleshooting – Liberty Pumps 331 User Manual

Page 3

©Copyright 2011 Liberty Pumps Inc. All rights reserved 3

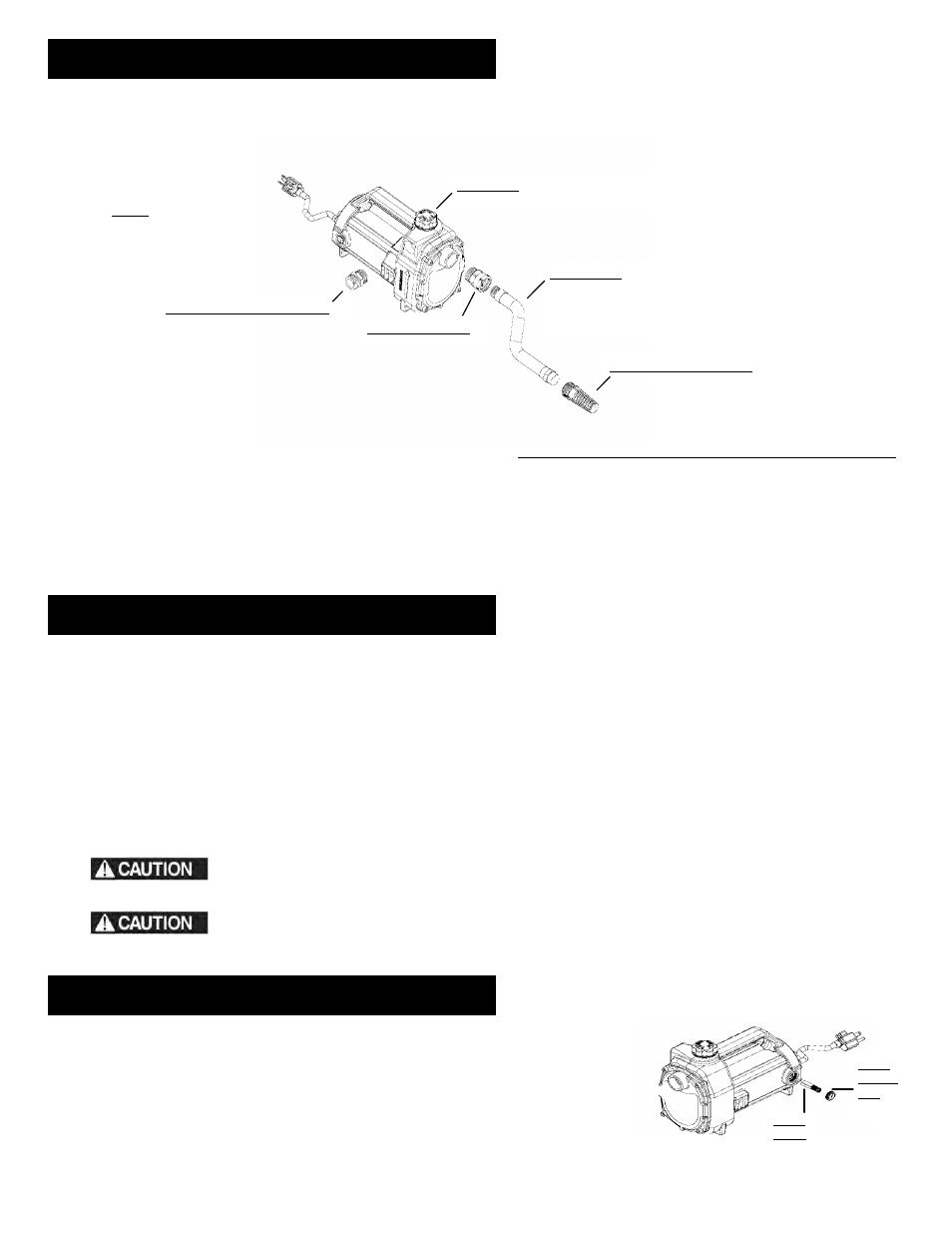

Brass male hose to male pipe

Prime plug – add water here prior to pump

operation.

Brass female hose

Suction hose (not included) - should not be

longer than needed (15’ maximum suction

lift). Use a high quality hose to prevent

collapsing.

Plastic male hose strainer

Motor

Brush

Brush

Access

Cap

Adapters are furnished with the pump. The inlet and discharge are threaded with a ¾” NPT. Standard water pipe can be threaded

directly into the casting. If a garden or other hose is to be used, the brass fittings must be installed. It is recommended that plumbing

tape or a pipe thread sealant when using the brass fittings. Liberty Pumps recommends that the swivel fitting be installed on the front of

the pump. NOTE: to reduce the possibility of hose collapse, use a high quality hose on the suction line (an ordinary garden hose may

collapse under suction pressure and should not be used).

Fig. 2

A strainer is furnished and should be used if pumping from a creek, pond, or source where foreign objects may be sucked into the

pump. The strainer helps prevent solids from entering the inlet line.

This pump must be filled with water before operating.

Running the pump dry will cause damage to the shaft seal. This unit is not waterproof or weatherproof and should not be used in

showers, saunas, or other potentially wet locations. The motor is designed for use in a clean, dry location. The unit draws fresh air in

from the back and blows warm air out the sides, do not block air vents. Ambient temperatures around the motor should not exceed

104°F (40°C) in order to adequately cool motor. The motor is equipped with a thermal protector. If the motor temperature rises, the unit

will automatically turn-off. To reset the thermal switch simply unplug the unit or turn the electrical switch from on to off and allow unit to

cool. The switch must be in the off position in order for it to cool down. Please note that the water temperature should not exceed 140°

F.

1.

IMPORTANT:

Pump must be primed before operating to prevent shaft seal failure. To do this, remove the prime plug

(see Fig. 2) & fill the housing with water (approx. 2 cups). Replace the prime plug (hand-tighten only).

2. Connect garden hoses, making sure each connection is tight. A pin hole leak in the suction hose will prevent the unit from priming.

If using a garden hose, be sure to use a new rubber gasket.

3. Plug the power cord into a properly fused and grounded GFCI electrical outlet. Turn the power switch to the “on” position. The

amount of time it takes the pump to prime depends on the suction line length and height. A maximum vertical suction lift of 15 feet

through a ¾” diameter garden hose could take up to 2 minutes to prime.

4. A check valve installed near the bottom of the suction hose (not included) is recommended for suction lifts of more than 10 feet

(this reduces the amount of time required to draw water).

5.

Please note that this pump retains water after use. In areas that are prone to freezing temperatures, please

be sure to drain the pump before storing it.

6.

When used to transfer materials other than clear water (such as glycol), the pump must be flushed with

water and drained before storage to prevent potential pump damage. Some chemicals used in hydronic

systems can result in corrosion of the aluminum pump housing.

The Model 331 operates with a brush-type motor. To remove brushes for replacement or

cleaning, disconnect the power cord from electrical supply. Remove the brush caps by

turning them with a screwdriver counterclockwise. The brushes are attached to coil

springs, which pull outward from the pump. If used brushes are to be reinserted, mark the

location of each brush (left or right) and reinstall on the same side, in the same orientation.

Brush replacement should be scheduled after approximately every 300 hours of use.

3. Installation

4. Operation

5. Maintenance and Troubleshooting