Trouble-shooting – Liberty Pumps 230-Series User Manual

Page 5

©Copyright 2012 Liberty Pumps Inc. All rights reserved

- 5 -

9.

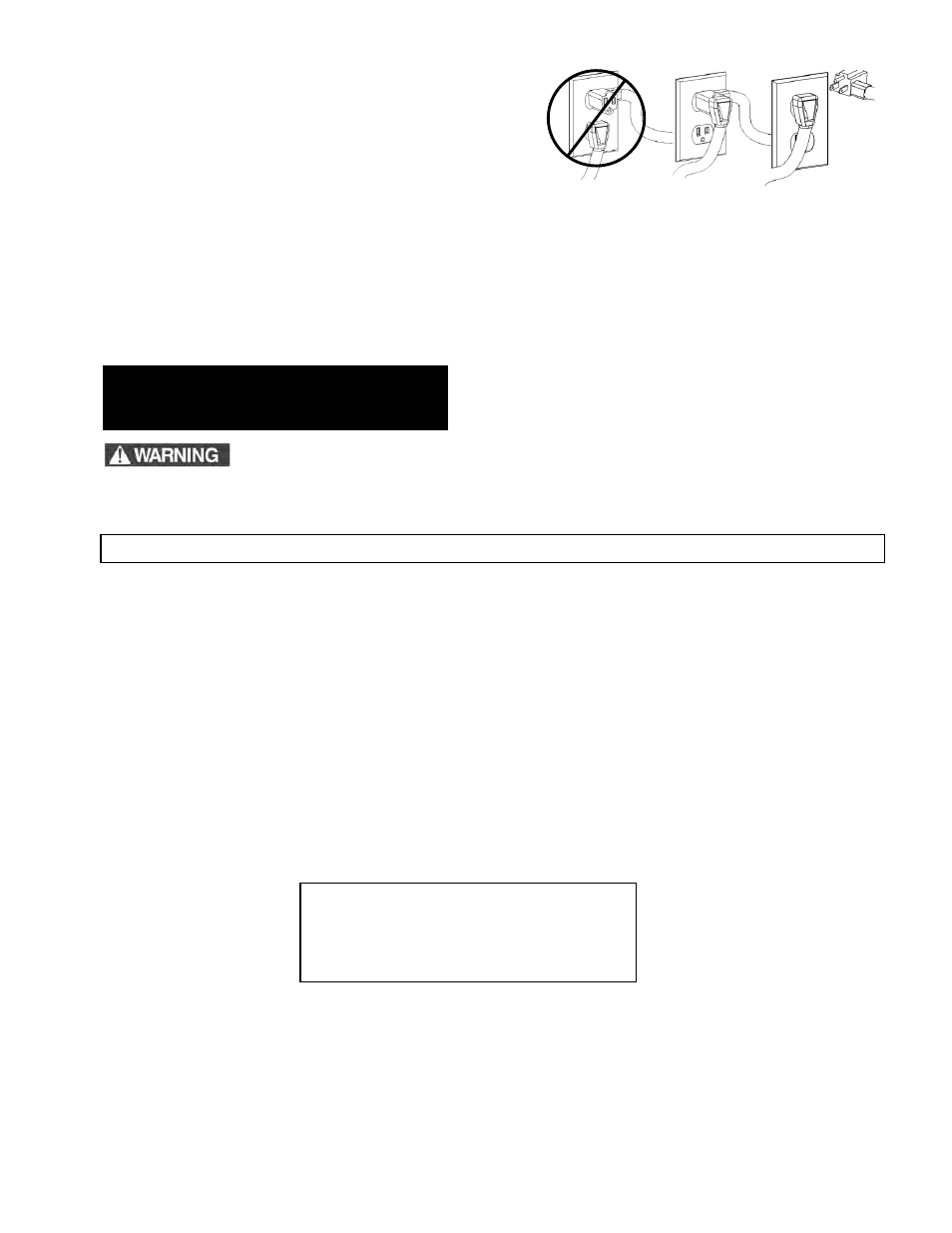

Models 243, 233, and 453 come factory-equipped with

a float switch mounted to the pump. This model has

two cords - one to the float switch and the other to the

pump motor. The switch cord has a series (piggyback)

plug enabling the pump (motor) cord to be plugged into

the back of it (see Fig. at right). The purpose of this

design is to allow temporary manual operation of the

pump if desired.

10.

For manual submersible models: Manual (switchless) models may be operated by directly plugging into an

approved electrical outlet. To prevent excessive seal wear and overheating, pumps should not be run dry for

extended periods of time. A minimum 4-1/2” water level is recommended.

If manual models are to be used with

an optional control device, follow the instructions provided with that control and make power connections per

those instructions. Set the turn-off level at 4-1/2” or greater. Do not remove float rods from VMF models for

manual use, as switch damage will result.

4.

Trouble-Shooting

Always disconnect the pump from power source before handling. This guide is designed

to help identify reasons for potential operating problems. It is not a service guide.

Dismantling of pump voids

warranty. Servicing of pump other than simple cleaning of pump inlet or impeller should be referred to the factory

or its authorized service centers.

PUMP DOES NOT RUN OR HUM.

1. Line circuit breaker may be off, tripped or loose. Have certified electrician check fuse or breaker.

2. Water level in pit may be too low to activate switch. Add more water to pit.

3. Plug on power cord may not be making contact in receptacle. Check security and connection.

4. If the pump is using the series (piggyback) cord plug, the plugs may not be connected tightly together.

5. Float may be obstructed. Make sure float is free and not interfering with the pit wall or other obstruction.

6.

If all symptoms check OK, the motor winding may be open. Consult factory.

PUMP RUNS OR HUMS BUT DOES NOT DELIVER WATER.

1. Check valve may be installed backwards or is defective. Check to make sure it is installed properly and

flapper in valve is free to move.

2. Discharge line may be blocked or frozen. Check to see if line passes through cold areas or is blocked.

3. Pump may be air-locked. Make sure that an anti-airlock hole was drilled in discharge pipe. Submersible

models are factory equipped with a bleed hole already in base of pump. Ensure that this hole is not plugged.

4. Vertical lift may be beyond pumps capability. See chart below for your pump’s maximum lift capability

.

NOTE: At the pump’s maximum lift there will be no flow.

5.

Check to see if inlet screen of pump is plugged or the impeller is jammed. Remove the pump screen and

clean inlet and impeller as needed.

6. Pump Impeller may be jammed. Check for foreign material such as construction debris, stones, etc. that might

be preventing the impeller from rotating. Reminder: Make sure pump is disconnected from power source

before checking inlet and impeller area.

PUMP RUNS AND REMOVES WATER BUT DOES NOT SHUT OFF.

1. Float is stuck in the “on” position. Check to make sure the float is free to move up and down without

obstruction.

2.

Switch may be defective. Consult factory.

NOTE: The manufacturer assumes no responsibility for damage or injury due to disassembly in the field.

MODEL

MAX. LIFT

101

17’

230-Series

21’

240-Series

20’

450-Series

34’

DON’T!

Fig. 1 Piggyback plug installation.

TEMPORARY

MANUAL

OPERATION

NORMAL