Gorman-Rupp Pumps SFDV4B 1520149 and up User Manual

Page 10

OM-06407

SF SERIES

PAGE B - 2

INSTALLATION

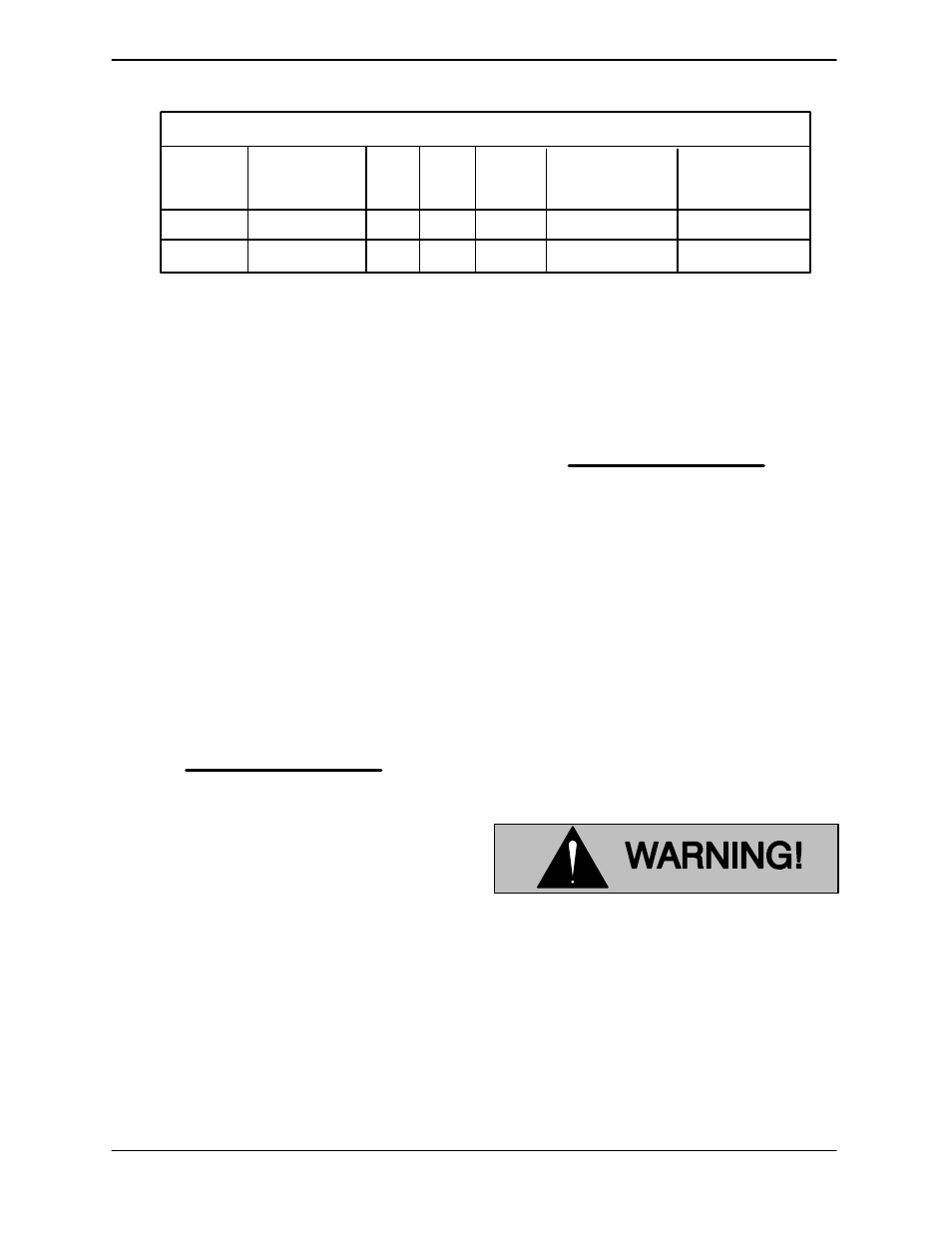

TABLE B-1. PUMP MOTOR SPECIFICATIONS

MODEL

VOLTAGE/

PHASE

SIZE

MOTOR

RPM

MAX

LOAD

AMPS

H.P.

LOCKED

ROTOR

AMPS

SFDV4B

208/3

4”

7.0

1750

22.0

184.7

SFDV4B

230‐460‐575/3

4”

7.5

1750

22.2/11.1/8.88

167.0/83.5/66.8

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer‐installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

Positioning the Pump

NOTE

Before installing and operating the pump, check

the direction of impeller rotation to ensure that the

pump is properly wired at the control box. See IM

PELLER ROTATION, SECTION C.

This pump is designed to be mounted on a stand in

a dry pit with an optional suction elbow.

Install and secure the stand in the floor of the dry

pit. Install the upper gasket on the stand, and posi

tion the pump on the stand. Install the lower gasket

on the suction elbow and secure the elbow to the

stand and pump with the provided screws.

Align the elbow with the system suction piping and

secure. Align the pump casing flange with the sys

tem discharge piping and secure.

Make certain that the pump and stand sit level in

the dry pit.

Piping

NOTE

Refer to Pump Performance in OPERATION -

SECTION C when determining the most efficient

piping installation.

This pump is designed for operation with an op

tional discharge elbow. Use rigid pipe to make dis

charge connections to the elbow.

The discharge line must be independently sup

ported to avoid vibration and strain on the pump.

For maximum pumping capacity, keep the line as

short and straight as possible. Elbows and fittings

used in a discharge line increase friction losses;

minimize their use.

It is recommended that a check valve or throttling

valve be installed in the discharge line to control si

phoning or back flow when the pump is shut off.

ELECTRICAL CONNECTIONS

Install and operate this pump in accor

dance with the National Electrical Code

and all local codes. Have a qualified

electrician perform all checks and con

nections in this section.

Never attempt to alter the length of the

pump motor cable or to repair it with a

splice. The power cable and pump mo

tor must be kept completely waterproof.

Serious damage to the pump and injury